Preparation process of high-strength and high-conductivity copper alloy and prepared copper alloy

A preparation process, copper alloy technology, applied in crucible furnaces, electric furnaces, rotary drum furnaces, etc., can solve the problems of short service life, inability to meet the high strength and high conductivity of high-voltage cable joints at the same time, surface corrosion and oxidation, etc. Electrical conductivity, improved strength and corrosion resistance, effect of improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

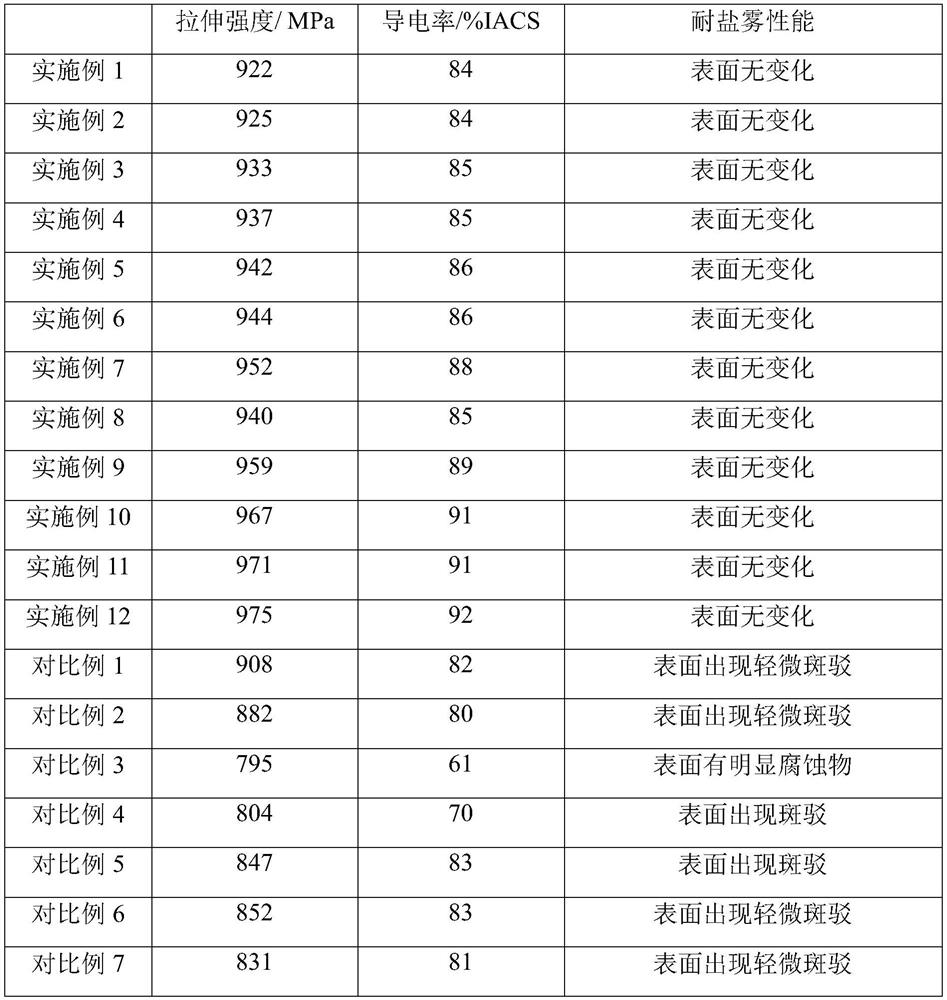

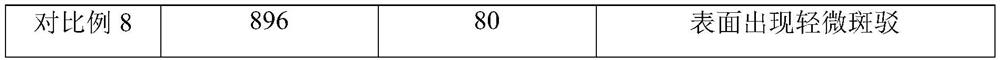

Examples

preparation example 1

[0046] The compound is prepared by the following steps:

[0047] Step 1, uniformly dispersing 0.7kg of carbon fiber and 0.5kg of titanium dioxide in an ethanol solution, ultrasonically treating, and evaporating the ethanol to dryness to obtain a solid product;

[0048] Step 2: Grind 1 kg of polyimide fiber and 2 kg of silicon powder into micropowders below 10 μm, then add solid product and 0.15 kg of dextrin for spray granulation to obtain particles below 0.1 mm.

preparation example 2

[0050] The compound is prepared by the following steps:

[0051] Step 1, uniformly dispersing 1.2 kg of carbon fiber and 1 kg of titanium dioxide in an ethanol solution, ultrasonically treating, and evaporating the ethanol to dryness to obtain a solid product;

[0052] Step 2: Grind 2 kg of polyimide fibers and 3.5 kg of silicon powder into micropowders below 10 μm, then add solid product and 0.22 kg of polyvinyl alcohol for spray granulation to obtain particles below 0.1 mm.

preparation example 3

[0054] The compound is prepared by the following steps:

[0055] Step 1, uniformly dispersing 1kg of carbon fiber and 0.8kg of titanium dioxide in an ethanol solution, ultrasonically treating, and evaporating the ethanol to dryness to obtain a solid product;

[0056] Step 2: Grind 1.5 kg of polyimide fiber and 2.7 kg of silicon powder into micropowders below 10 μm, then add solid product and 0.2 kg of polyvinyl alcohol for spray granulation to obtain particles below 0.1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com