Frame glue packaging structure and frame glue material preparation method

A packaging structure and frame glue technology, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of inconvenient digging, pollution of operation table and clean clothes, and difficult operation, so as to reduce the probability of residue and reduce the number of particles Risk, the effect of reducing material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

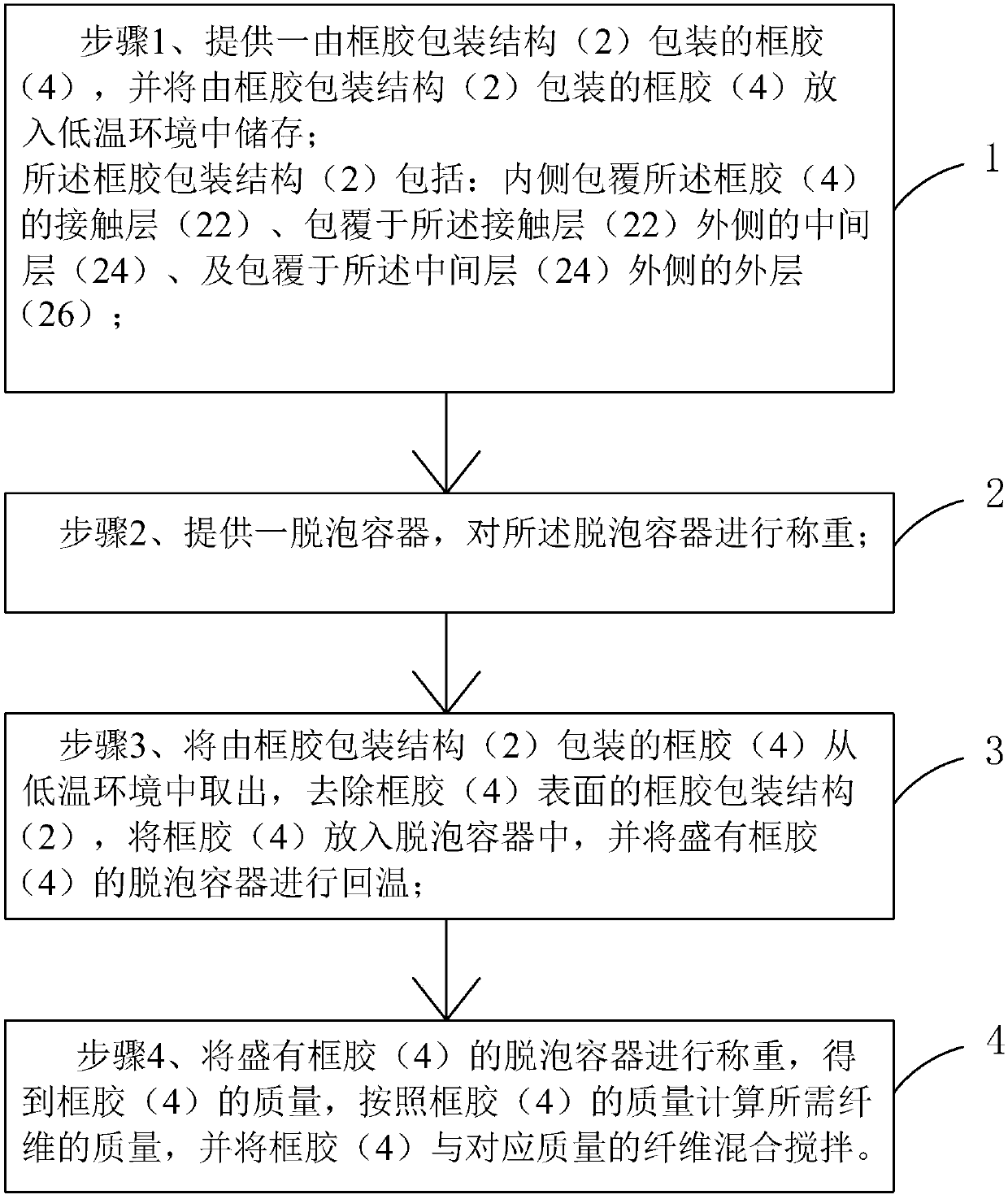

[0032] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

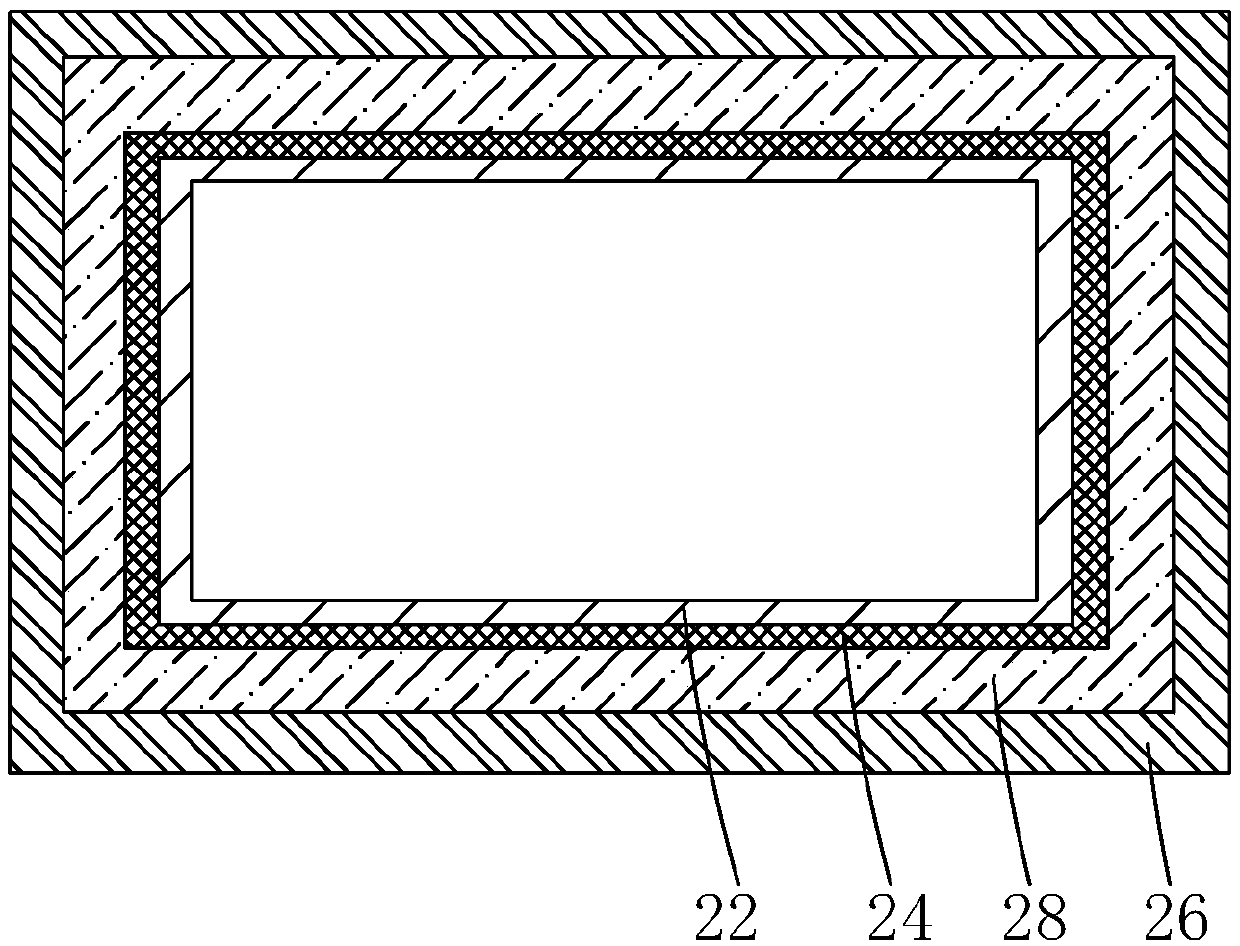

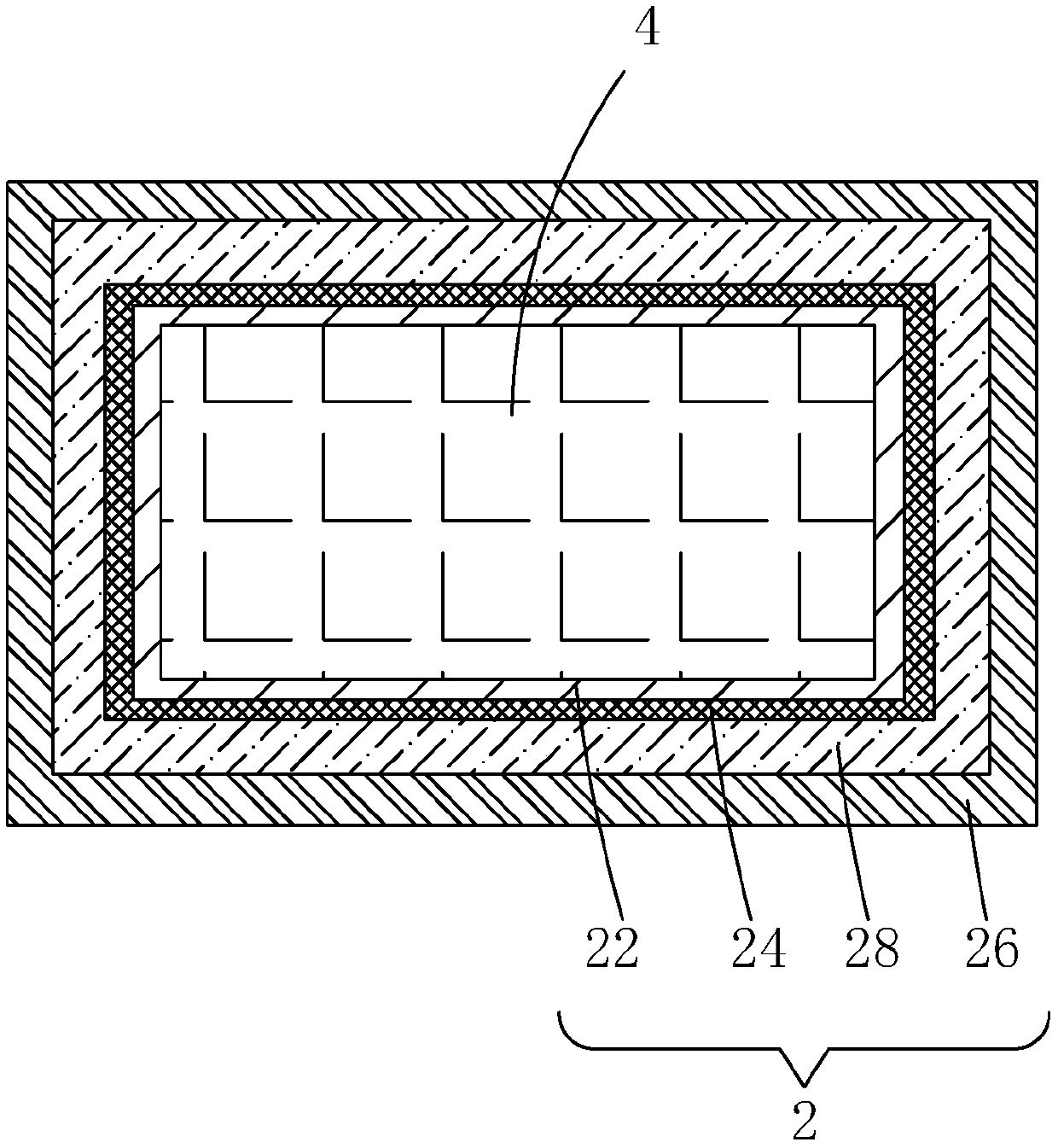

[0033] see figure 1 , the present invention firstly provides a plastic frame packaging structure, including: a contact layer 22 coated with a frame rubber inside, an intermediate layer 24 coated on the outside of the contact layer 22, and an outer layer coated on the outside of the intermediate layer 24 Outer layer 26.

[0034] Specifically, the outer layer 26 is a black or opaque plastic tank, which can prevent the sealant from being bumped, and at the same time prevent the sealant from being irradiated by light and deteriorating.

[0035] Specifically, the middle layer 24 is a plastic bag made of hard aluminum foil, and since the aluminum foil is opaque, it can further prevent light from shining on the sealant.

[0036] Specifically, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com