Weld joint machining technology and mechanical equipment with weld joints

A technology of processing technology and mechanical equipment, applied in metal processing equipment, machine tools suitable for grinding the edge of workpieces, manufacturing tools, etc., can solve the problem of food, medicine, germs and other pollutants that are easy to remain, food and medicine hygiene and safety Can not be guaranteed, production equipment hygiene can not be guaranteed and other problems, to achieve the effect of reducing residual pollutants, reducing the probability of residue, and reducing surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

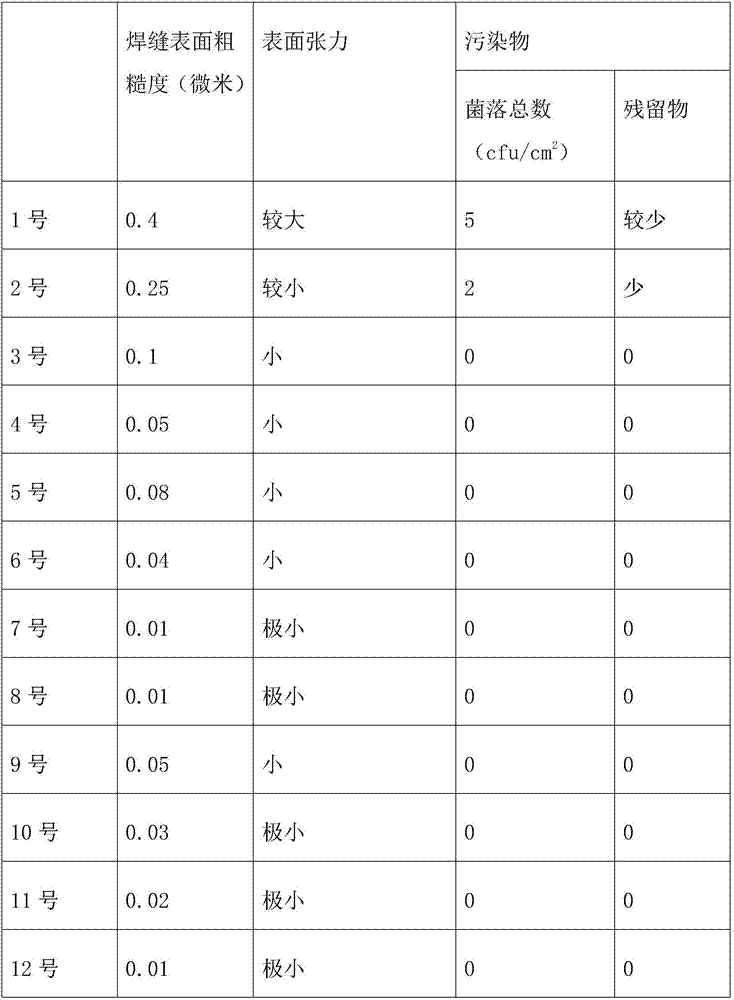

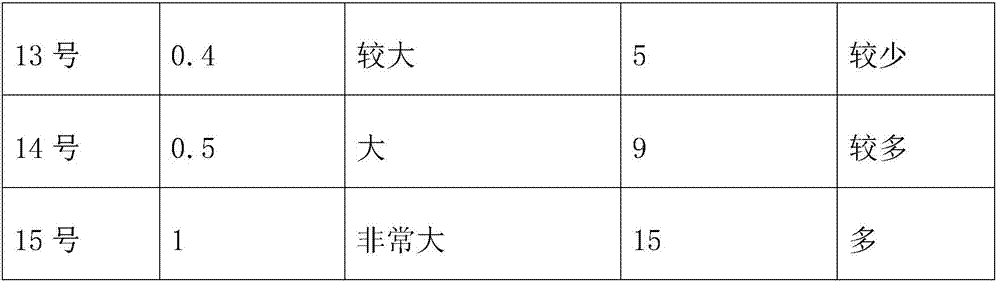

Embodiment 1

[0029] The present embodiment provides a kind of welding seam processing technology, see the following for details:

[0030] Use 150-mesh sandpaper to grind the weld seam until the surface roughness of the weld seam is 0.4 microns, and the grinding is completed. The sandpaper material in this embodiment is mainly Al2O3.

[0031] This embodiment also provides a mechanical device with a weld seam, the weld seam on the mechanical device with a weld seam is mainly made by the above welding seam processing technology.

Embodiment 2

[0033] The present embodiment provides a kind of welding seam processing technology, see the following for details:

[0034] Use 1500-mesh sandpaper to grind the weld seam until the surface roughness of the weld seam is 0.25 microns, and the grinding is completed. The sandpaper material in this embodiment is mainly Al2O3.

[0035] This embodiment also provides a mechanical device with a weld seam, the weld seam on the mechanical device with a weld seam is mainly made by the above welding seam processing technology.

Embodiment 3

[0037] The present embodiment provides a kind of welding seam processing technology, see the following for details:

[0038] Use 50-mesh sandpaper to grind the weld for the first time until the surface roughness of the weld is 5 microns to complete the first grinding. Continue to use 800-mesh sandpaper to grind the weld seam for the second time until the surface roughness of the weld seam is 0.1 micron, and complete the second grinding. In this embodiment, the sandpaper material is mainly diamond.

[0039] This embodiment also provides a mechanical device with a weld seam, the weld seam of the mechanical device with a weld seam is manufactured by the above welding seam processing technology.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com