Anti-icing material with electrothermal photothermal conversion capability and wear-resistant and super-hydrophobic multiple properties as well as preparation method and application of anti-icing material

A photothermal conversion, super-hydrophobic technology, applied in chemical instruments and methods, other chemical processes, epoxy resin coatings, etc., can solve the problems of unsatisfactory anti-icing effect, reduced icing adhesion, and low temperature resistance of composite materials. , to achieve the effect of large-scale preparation, good electric heating and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

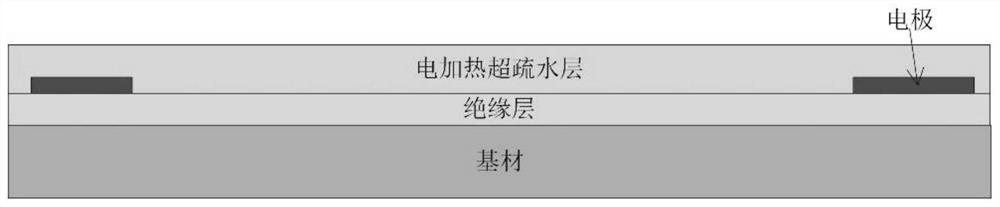

[0038] The present invention provides the preparation method of the anti-icing material described in the above technical solution, comprising the following steps:

[0039] Prepare an insulating layer on the surface of the substrate layer;

[0040] Arrange parallel electrodes on the surface of the insulating layer;

[0041] Mixing the fluorinable grafted polymer matrix, nano-conductive particles, nano-photothermal particles, nano-hydrophobic particles, ammonium fluoride salt curing agent and organic solvent to obtain a paint mixture; spraying the paint mixture on a surface with parallel electrodes arranged After the surface of the insulating layer is cured, the anti-icing material is obtained.

[0042] The process of preparing the anti-icing material in the present invention is as follows: image 3 shown.

[0043] In the present invention, the method for preparing the insulating layer is preferably: dissolving the insulating material in an organic solvent to obtain an insula...

Embodiment 1

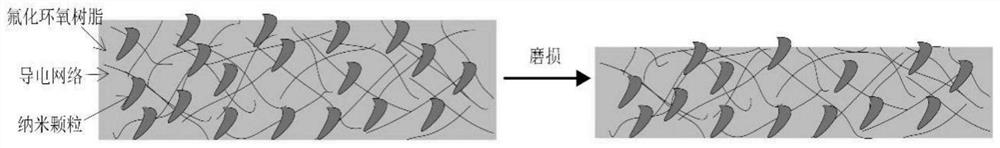

[0048] An anti-icing material with electrothermal photothermal conversion capability and wear-resistant super-hydrophobic multi-performance, the preparation method is as follows:

[0049] The metal substrate to be sprayed is textured, and after textured, the surface of the metal substrate is sprayed with a polyurethane insulating layer, and after the insulating layer is cured, the copper foil parallel electrodes are arranged, and the distance between the parallel electrodes is 10 cm;

[0050] Add nano conductive particle graphite powder, nano photothermal particle ferric oxide particle, nano hydrophobic particle PTFE particle and organic solvent xylene to epoxy resin, and sequentially perform mechanical stirring and ultrasonic dispersion to obtain electrothermal photothermal superhydrophobic coating dispersion; The mass of graphite powder, ferric oxide particles and PTFE particles are respectively 20%, 20% and 80% of the mass of epoxy resin, and the mass of organic solvent is 1...

Embodiment 2

[0057] A kind of anti-icing material with electrothermal photothermal conversion ability and wear-resistant super-hydrophobic multi-performance, the preparation method is as follows:

[0058] The epoxy resin composite material substrate to be sprayed is textured, and an epoxy resin insulating layer is sprayed on the surface of the composite material substrate after textured. After the insulating layer is cured, the copper foil parallel electrodes are arranged, and the parallel electrode interval is 8cm;

[0059] Add nano conductive particle graphene, nano photothermal particle nano gold powder, nano hydrophobic particle alumina nanoparticle and organic solvent xylene to epoxy resin, mix thoroughly, and perform mechanical stirring and ultrasonic dispersion in turn to obtain electrothermal photothermal superhydrophobic coating dispersion liquid; wherein the mass of graphene, nano-gold powder, and alumina nanoparticles are 5%, 15%, and 30% of the mass of epoxy resin, and the mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com