Diaphragm for solid electrolyte of lithium battery and preparation method of diaphragm

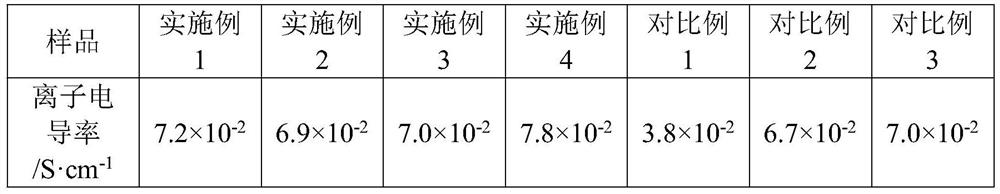

A solid electrolyte, lithium battery technology, applied in electrolytes, secondary batteries, and secondary battery repair/maintenance, etc., can solve the problems of stable operation of electrolytes, inability to effectively popularize and apply magnesium borate nanowires, and poor cycle stability. Achieving the effect of excellent ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of surface-grafted polymer brushed magnesium borate nanowires: magnesium nitrate hexahydrate and sodium tetraborate were added to water in a mass ratio of 1:1.5, then heated to 220°C and kept for 36h, and then the resulting precipitate was 100°C After drying for 4 h, after grinding, it was placed in a tube furnace for calcination at 700 °C for 2 h to obtain magnesium borate nanowires; the obtained magnesium borate nanowires were dispersed in polyvinylidene fluoride dimethyl sulfoxide solution with a concentration of 2 mg / mL, Then, it was centrifuged at 4000 rpm, dried, and put into an oven for annealing at 160° C. for 48 hours to prepare surface-grafted polymer brushed magnesium borate nanowires.

[0035] (2) Add 25 parts of lithium bistrifluoromethane yellow imide, 20 parts of polyethylene glycol, 15 parts of lanthanum oxide, 8 parts of polydimethylsiloxane and 1 part of methyl methacrylate into 80 parts of N,N- In dimethylformamide, stir under argon at...

Embodiment 2

[0039] (1) Preparation of surface-grafted polymer brushed magnesium borate nanowires: magnesium nitrate hexahydrate and sodium tetraborate were added to water in a mass ratio of 1:1, then heated to 200 °C and kept for 36 h, and then the resulting precipitate was 100 °C After drying for 4 h, put it into a tube furnace for calcination at a high temperature of 700 °C for 2 h to obtain magnesium borate nanowires; disperse the obtained magnesium borate nanowires in a polyethylene glycol aqueous solution with a concentration of 2 mg / mL, and then rotate at 4000 rpm. Centrifugation, drying, and annealing at 160° C. for 48 hours in an oven to prepare surface-grafted polymer brushed magnesium borate nanowires.

[0040] (2) 30 parts of lithium hexafluorophosphate, 25 parts of polyvinylidene fluoride, 20 parts of lithium oxide, 3 parts of polydimethylsiloxane and 1.5 parts of acrylate were added to 60 parts of N,N-dimethylacetamide, under argon Stir under the atmosphere, and mix evenly to...

Embodiment 3

[0044] (1) Preparation of surface-grafted macromolecular brushed magnesium borate nanowires: magnesium nitrate hexahydrate and sodium tetraborate were added to water in a mass ratio of 1:2, then heated to 250 °C and kept for 24 h, and then the resulting precipitate was precipitated at 100 °C After drying for 4 hours, put it into a tube furnace for calcination at a high temperature of 700 °C for 2 hours to obtain magnesium borate nanowires; disperse the obtained magnesium borate nanowires in a polymethacrylic acid aqueous solution with a concentration of 2 mg / mL, and then rotate at 4000 rpm. Centrifugation, drying, and annealing at 160° C. for 48 hours in an oven to prepare surface-grafted polymer brushed magnesium borate nanowires.

[0045] (2) 20 parts of lithium perchlorate, 30 parts of polyacrylonitrile, 10 parts of zirconium oxide, 5 parts of polydimethylsiloxane and 2 parts of methyl methacrylate were added to 70 parts of dimethyl sulfoxide, in Stir under argon atmosphere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com