Water-based polytetrafluoroethylene heat-gathering-preventing magnetic-conducting non-stick coating and preparation method thereof

A polytetrafluoroethylene, non-stick coating technology, applied in the direction of magnetic coatings, coatings, etc., can solve the problems of non-stick coating not having magnetic conductivity, affecting the effect of electromagnetic heating, uneconomical, etc., and achieving excellent non-stick performance. , The effect of improving uniform dispersion and high electromagnetic heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

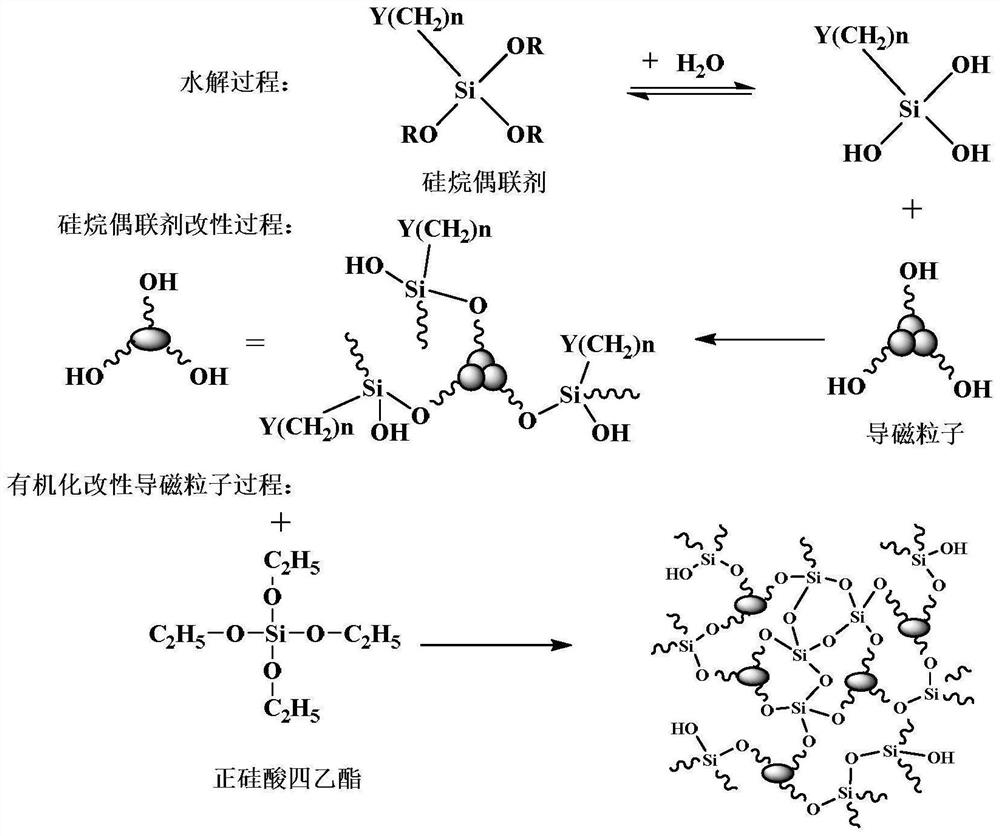

[0033] A preparation method of water-based polytetrafluoroethylene polytetrafluoroethylene anti-polymerization heat-conducting magnetic non-stick coating, comprising the following steps:

[0034] 1) Preparation of organically modified magnetically conductive particles: Disperse the magnetically conductive particles in a total amount of 40-60% of water through a pre-dispersion process (ultrasonic or grinding or a combination thereof) to form a slurry of magnetically conductive particles, then add silane coupling Combined agent, stir (200-500rpm) at room temperature for 3-5h and then filter, add a total of 40-60% tetraethyl orthosilicate, heat up to 50-85°C, stir (200-500rpm) after heating After 2-4 hours, the organically modified magnetic permeable particles are obtained after separation.

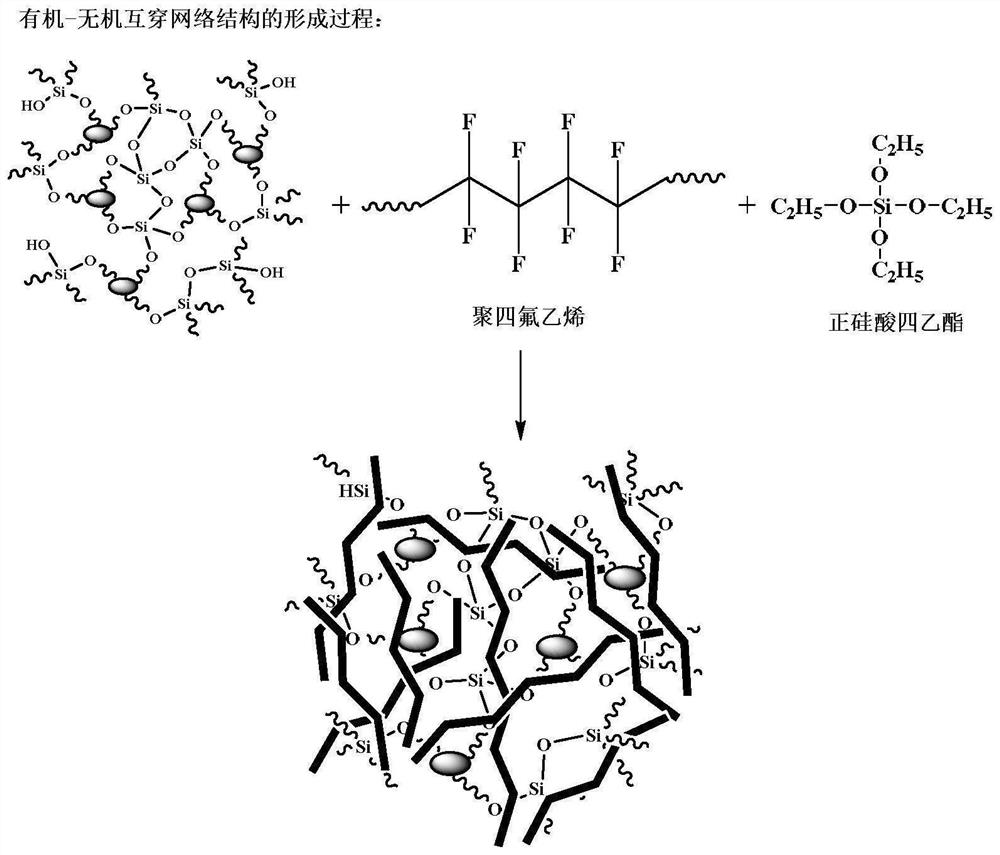

[0035] 2) Preparation of water-based polytetrafluoroethylene anti-polythermal, magnetically conductive and non-stick coating: adding the organically modified magnetically conductive particle...

Embodiment 1

[0037] 1) Preparation of organically modified magnetic conductive particles:

[0038] Disperse 20 parts of silver powder of magnetically conductive particles in 12 parts of water by ultrasonic process to form a slurry of magnetically conductive particles, add 4 parts of γ-(2,3-glycidyloxy)propyltrimethoxysilane, at room temperature 200rpm After stirring and reacting for 5 hours, filter, add a total of 1.2 parts of tetraethyl orthosilicate, raise the temperature to 50° C., stir and react at 200 rpm for 4 hours after heating, and obtain organically modified magnetically conductive particles.

[0039] 2) Preparation of water-based polytetrafluoroethylene anti-polymerization thermal conductivity and magnetic non-stick coating:

[0040] Add the organically modified magnetically conductive particles prepared in step 1) to a mixture of 60 parts of 60wt% polytetrafluoroethylene emulsion and 1.8 parts of tetraethyl orthosilicate, raise the temperature to 50°C, and stir at 200rpm for 4 ...

Embodiment 2

[0043] 1) Preparation of organically modified magnetic conductive particles:

[0044] Disperse 9 parts of magnetically conductive particle iron powder and 1 part of holmium oxide powder in 4 parts of water by grinding process to form a slurry of magnetically conductive particles, add 2 parts of γ-methacryloxypropyl trimethoxysilane, Stir and react at 500 rpm at room temperature for 3 hours, then filter, add a total of 0.6 parts of tetraethyl orthosilicate, heat up to 85°C, and stir and react at 500 rpm for 2 hours after heating to obtain organically modified magnetic permeable particles.

[0045] 2) Preparation of water-based polytetrafluoroethylene anti-polymerization thermal conductivity and magnetic non-stick coating:

[0046] Add the organically modified magnetically conductive particles prepared in step 1) to a mixture of 20 parts of 60wt% polytetrafluoroethylene emulsion and 0.4 parts of tetraethyl orthosilicate, raise the temperature to 85°C, and stir at 500rpm for 2 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com