Fluorine-free high-early-strength liquid alkali-free accelerator as well as preparation method and application thereof

A technology of quick-setting agent and early-strength agent, which is applied in the field of building material additives, can solve the problems of low-dosage quick-setting effect, hinder C3 hydration, and high-dosage problems, achieve green production costs, shorten the hydration incubation period, and improve the preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides a fluorine-free high early strength liquid alkali-free accelerator and its preparation method, the specific details are as follows:

[0055] S1: Preparation of complexation activator:

[0056] S11: 35 parts by weight of acrylamide, 10 parts by weight of vinyltriethoxysilane, 47.5 parts by weight of sodium p-styrenesulfonate, 2.5 parts by weight of sodium methacrylsulfonate, 2.0 parts by weight of persulfuric acid Add ammonium and 300 parts by weight of deionized water into the reactor, stir to dissolve and heat up to 40°C;

[0057] S12: Add a mixed solution of 0.5 parts by weight of sodium bisulfite and 50 parts by weight of deionized water dropwise at a uniform speed for 1 hour, continue to react for 1 hour after the addition, cool down to room temperature, and add 60 parts by weight of deionized water water to obtain a complexation activator at a concentration of 20% by weight.

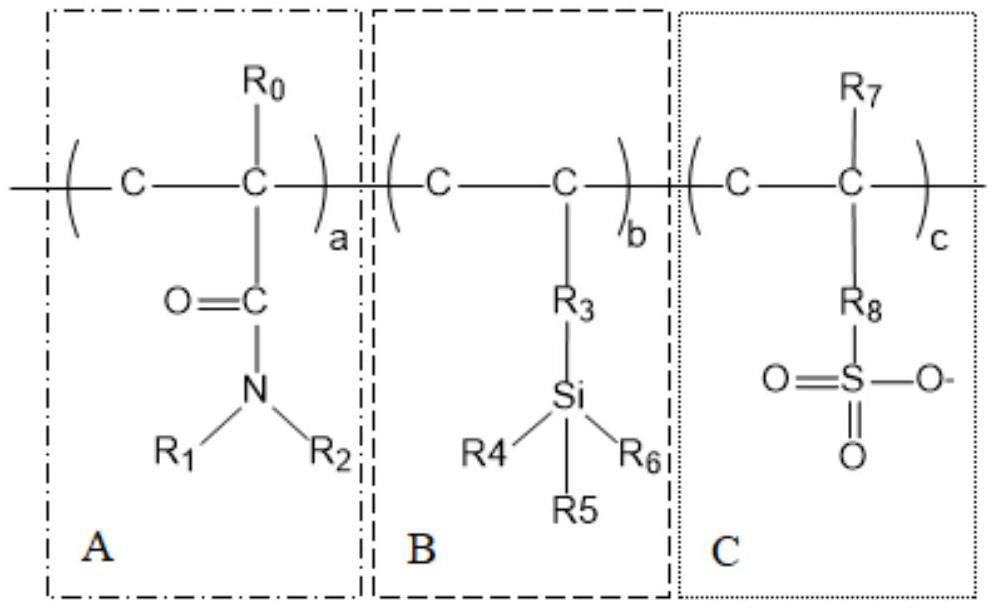

[0058] The complexation activator obtained in Example 1 is car...

Embodiment 2

[0065] This embodiment provides a fluorine-free high early strength liquid alkali-free accelerator and its preparation method, the specific details are as follows:

[0066] S1: Synthesis of complexation activator:

[0067] S11: Bottom solution: 30 parts of N,N-dimethylacrylamide + 7.5 parts of 3-methacryloxypropyltrimethoxysilane + 62.5 parts of 2-acrylamide-2-methylpropanesulfonic acid + over 1.0 parts of ammonium sulfate + 300 parts of deionized water, initial reaction temperature: 30°C;

[0068] S12: Dropping solution: 0.25 parts of vitamin C + 50 parts of deionized water, adding time of 0.5 hours, reaction time of 2 hours; add 55 parts of deionized water, and get a complexing activator with a concentration of 20% after cooling down to room temperature .

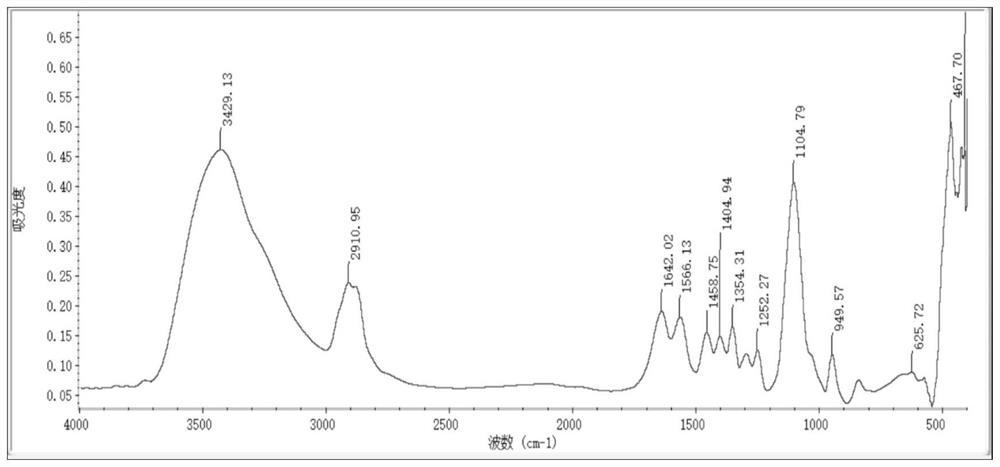

[0069] The complexation activator prepared in embodiment 2 is carried out infrared spectrum (IR) detection, as figure 1 As shown, at ~2910cm -1 、~1354cm -1 Nearby - CH 3 Characteristic absorption peak at ~1404cm -1...

Embodiment 3

[0074] This embodiment provides a fluorine-free high early strength liquid alkali-free accelerator and its preparation method, the specific details are as follows:

[0075] S1: Synthesis of complexation activators:

[0076] S11: Bottom solution: 20 parts of N-methylolacrylamide + 5 parts of vinyltriacetoxysilane + 72.5 parts of 2-acrylamide-2-methylpropanesulfonic acid + 2.5 parts of sodium methacrylsulfonate + over 1.5 parts of ammonium sulfate + 300 parts of deionized water, initial reaction temperature: 30°C;

[0077] S12: Dropping solution: 0.3 parts of white block + 50 parts of deionized water, adding time of 0.5 hours, reaction time of 1.5 hours; add 55 parts of deionized water, and get a complex excitation with a concentration of 20% after cooling down to room temperature agent.

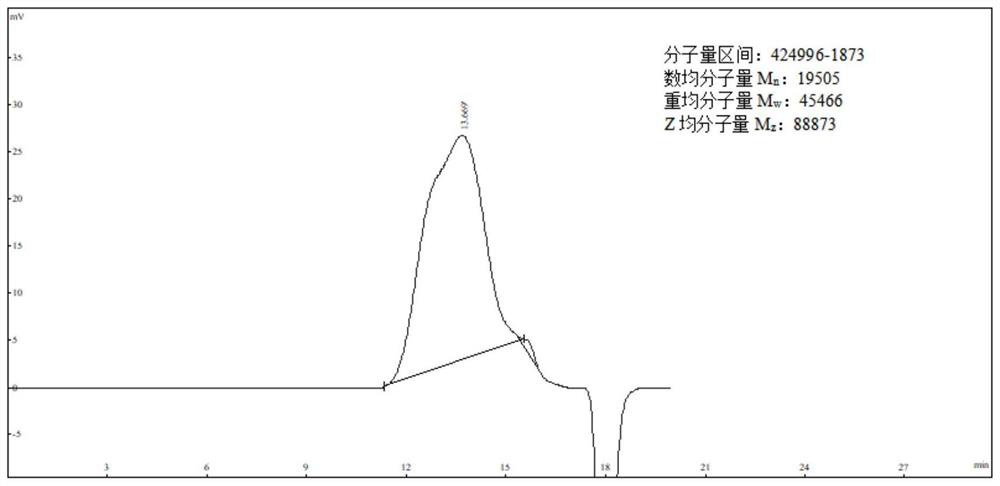

[0078] The complexation activator obtained in Example 3 is carried out to gel permeation chromatography (GPC) detection, the synthetic complexation activator polymer molecular weight distrib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com