Grinding wheel for roughing and thinning mobile phone backboard glass and preparation method of grinding wheel

A backplane glass, mobile phone technology, applied in manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of low strength and low life, and achieve improved life, increased control, good sharpness and resistance. deformable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0018] Three-dimensionally mix diamond (400#) with epoxy resin and 1-3μm copper-tin-titanium (70-15-15) alloy powder in an acetone environment for 60 minutes, then dry and sieve through 60 meshes to obtain packages with uniform particle size The diamond particles of the alloy powder are used in the following examples; the mass ratio of diamond and copper-tin-titanium alloy powder is 2.5:1, and the epoxy resin is 1% of the total mass of diamond and copper-tin-titanium alloy powder.

[0019] The following grinding wheel preparation process:

[0020] (1) Material mixing: According to the formula requirements of a certain proportion, put the precisely weighed copper powder, tin powder, and cobalt powder into the tank in turn, perform ball milling, add 25% alcohol in total mass, and then put steel balls, The ratio of ball to material is 2:1 (wt.%), the rotation speed is 500rpm, and the ball mill is 60min. Take out the ball material, scrape off all the material on the inner wall of...

Embodiment 1

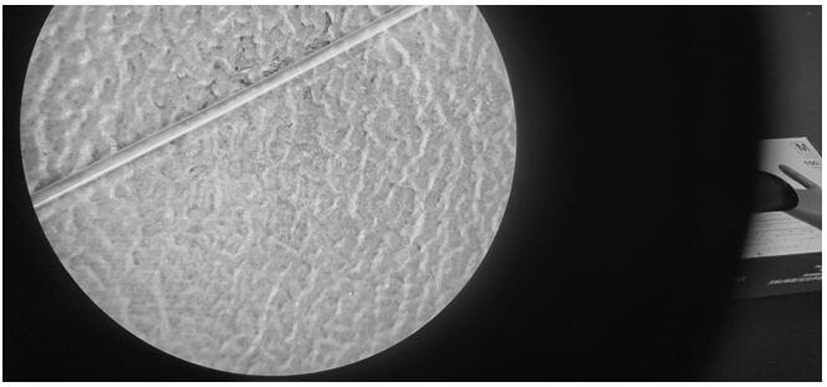

[0025] Accurately weigh 62% copper powder, 17.5% tin powder, and 20.5% cobalt powder, ball mill several raw materials to form a binder, and mix with diamond wrapped in alloy powder at a volume ratio of 70%: 30% to prepare molding materials. Weigh the molding material according to the unit weight requirements, and carry out pressing, sintering and shape processing. Thinning processing of glass with a size of 150*75, within the processing life, the split rate is 1.02%, and the processing life of the grinding wheel can reach 1500pcs (pieces). See the product photo after processing figure 1 .

Embodiment 2

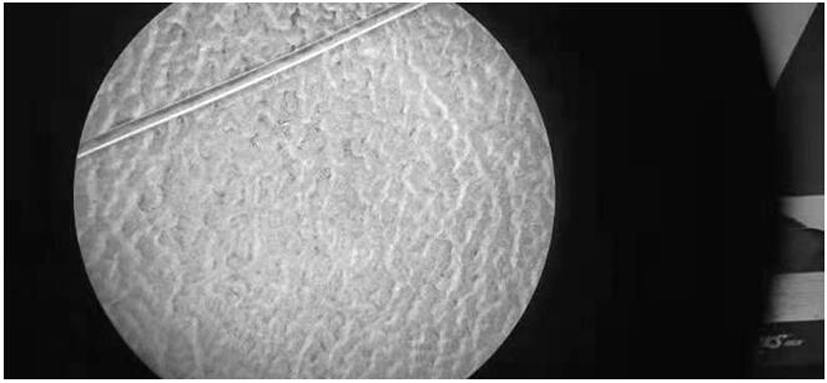

[0027] Accurately weigh 65.5% copper powder, 16.1% tin powder, and 18.4% cobalt powder, and ball-mill several raw materials to form a binder, which is mixed with diamond wrapped in alloy powder at a volume ratio of 70%: 30% to prepare molding materials. Weigh the molding material according to the unit weight requirements, and carry out pressing, sintering and shape processing. Thinning processing of glass with a size of 150*75, within the processing life, the split rate is 1.22%, and the processing life of the grinding wheel can reach 1300pcs. After processing, see the photo of the product figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com