Titanium dioxide composite material and preparation method and application thereof

A technology of titanium dioxide and composite materials, applied in chemical instruments and methods, electrolytic coatings, chemical/physical processes, etc., to achieve the effects of increasing photocatalytic performance, strong regulation, antibacterial and anti-inflammatory cell proliferation and mineralization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

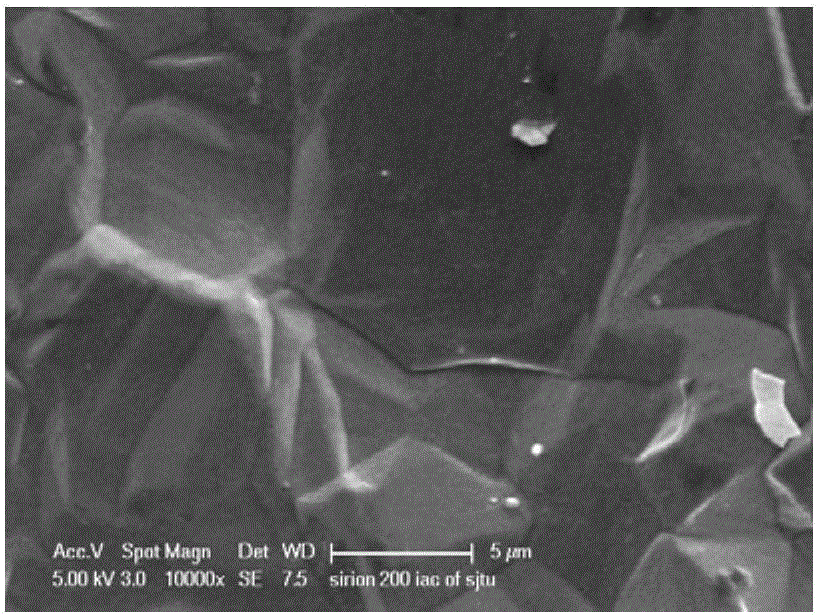

Image

Examples

Embodiment 1

[0068] Example 1 Preparation of fluorine-doped smooth titanium dioxide film by anodic oxidation

[0069] Adopt composite electrolyte (containing ethanol) to carry out anodic oxidation and prepare smooth titania film step as follows:

[0070] (1) Titanium alloy Ti-Zr pretreatment: the alloy is polished smooth, immersed in the pickling solution, chemically polished for 10s, then rinsed with deionized water and absolute ethanol in turn, and dried for later use; wherein the pickling solution is HF, HNO 3 Mixed solution with deionized water, the volume ratio is 1:1.5:50;

[0071] (2) Preparation of electrolyte: a certain amount of HF, H 3 PO 4 Dissolve in 20mL deionized water and 10mL absolute ethanol to obtain 0.1mol / L H 3 PO 4 , a mixed solution of 0.8wt% HF, which is used as the electrolyte;

[0072] (3) Anodic oxidation: put the pretreated titanium sheet as the anode and the platinum sheet as the cathode in the electrolyte in (2) for anodic oxidation, using a DC power sup...

Embodiment 2

[0077] Example 2 Preparation of fluorine-doped carbon composite porous titanium dioxide film by anodic oxidation

[0078] The steps of preparing porous titanium dioxide film by anodic oxidation using composite electrolyte solution (containing ethanol and carbon source) are as follows:

[0079] (1) Pretreatment of medical titanium alloy Ti-35Nb-5Ta-7Zr: the alloy is polished smooth, immersed in pickling solution, chemically polished for 20s, and then rinsed with deionized water and absolute ethanol in turn, dried and set aside; The pickling solution is HF, HNO 3 Mixed solution with deionized water, the volume ratio is 2:3:100;

[0080] (2) Preparation of electrolyte: ①Dissolve a certain amount of biomass-derived carbonaceous mesophase in 90mL of absolute ethanol, stir and dissolve to obtain solution a; ②Dissolve a certain amount of HF, H 3 PO 4 Dissolve in 10.1mL deionized water to obtain solution b; ③ Mix solutions a and b to obtain a carbonaceous mesophase with a concentra...

Embodiment 3

[0086] Example 3 Preparation of fluorine-doped carbon composite three-dimensional ordered titanium dioxide nanotubes by anodic oxidation

[0087] The steps for preparing three-dimensional ordered titanium dioxide nanotubes by anodic oxidation using composite electrolyte (containing methanol and carbon source) are as follows:

[0088] (1) Pretreatment of medical titanium alloy Ti-12Mo-6Zr-2Fe: the alloy sheet is polished smooth, immersed in pickling solution, chemically polished for 26s, and then rinsed with deionized water and absolute ethanol in turn, dried and set aside; The pickling solution is HF, HNO 3 Mixed solution with deionized water, the volume ratio is 2:1.8:100;

[0089] (2) Preparation of electrolyte: ①Dissolve a certain amount of biomass-derived carbonaceous mesophase in 80mL of methanol, stir and dissolve to obtain solution a; ②Dissolve a certain amount of HF, H 3 PO 4 Dissolve in 20mL deionized water to obtain solution b; ③ Mix solutions a and b to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com