Preparation process of high-strength integrally-formed micro-inductor

A preparation process and micro-inductance technology, applied in the field of microelectronics, can solve the problems of affecting micro-inductance, non-conductive resistance, easy to break under force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

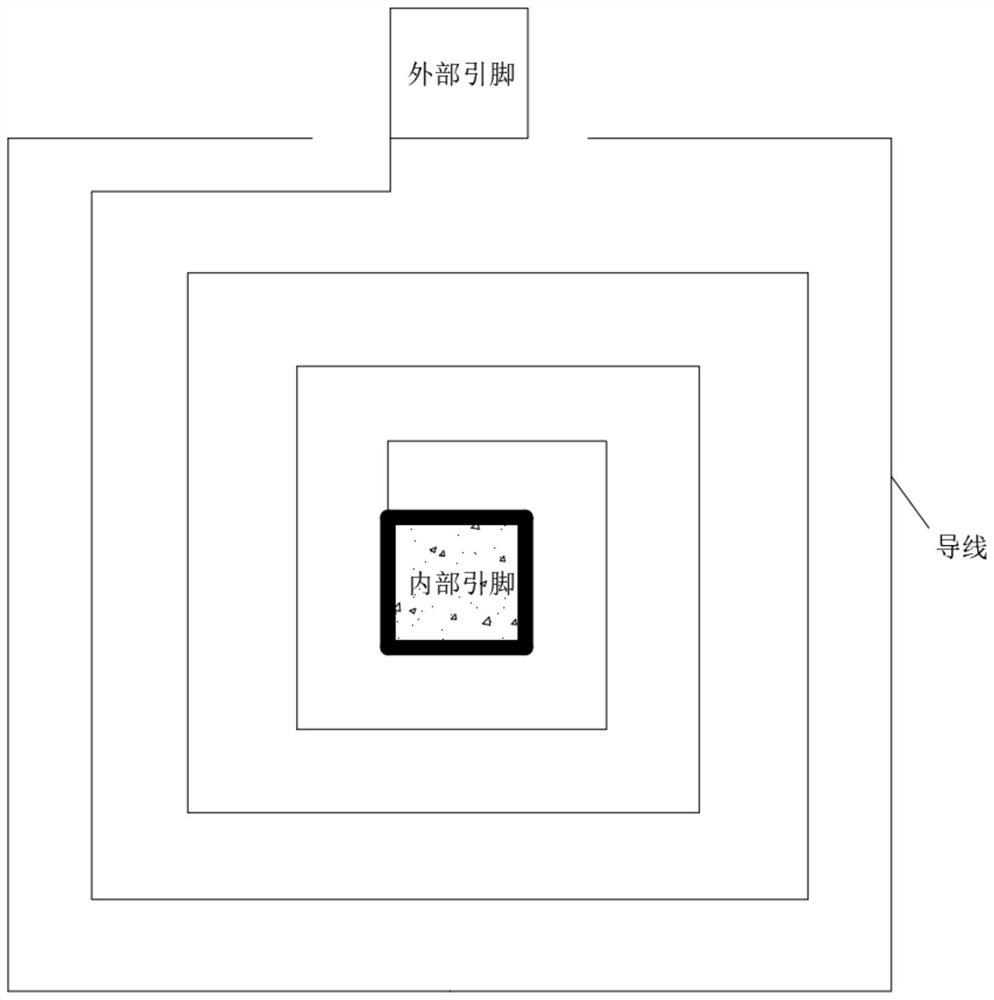

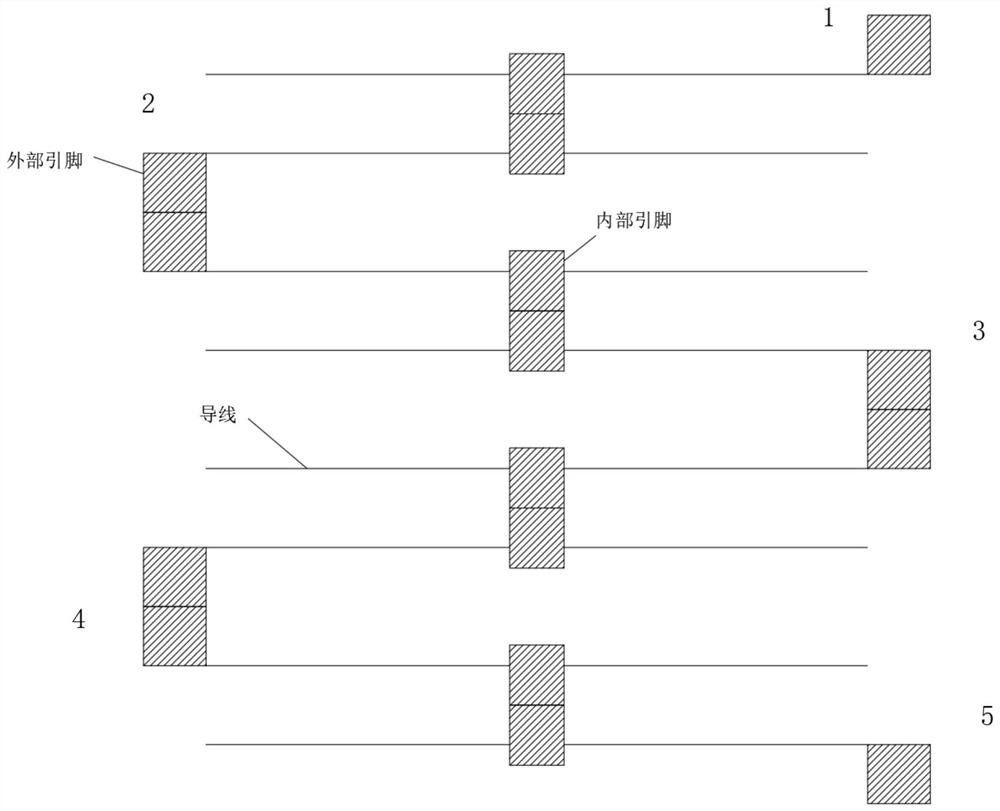

[0029] A high-strength integral molding micro-inductor preparation process, the high-strength integral molding micro-inductance preparation process mainly includes the following preparation steps:

[0030] (1) Coil production: under the conditions of pressure 1Pa, argon gas flow rate 15sccn, sputtering power 100w, sputtering rate 4nm / min, temperature 20°C, sputter 0.3μm on a smooth silicon dioxide substrate by magnetron sputtering For a thick chromium layer, spin-coat photoresist AZ P4620 to a thickness of 4 μm on the chromium layer at 3000r / min, and then stand at 20°C for 20min, 50°C for 60min, 90°C for 6h, and 110°C for 60min. Baking, cooling to 20°C, covering the photoresist with a photomask for contact exposure, exposure time 60s, then immersing in pure water at 20°C for 5 minutes to develop, cleaning the surface with absolute ethanol for 3 times, at 350g / L Copper plating is carried out in an electroplating solution of copper sulfate and 30mL / L sulfuric acid, at a current ...

Embodiment 2

[0035] A high-strength integral molding micro-inductor preparation process, the high-strength integral molding micro-inductance preparation process mainly includes the following preparation steps:

[0036] (1) Coil production: under the conditions of pressure 2Pa, argon gas flow rate 18sccn, sputtering power 120w, sputtering rate 5nm / min, temperature 25°C, sputter 0.4μm on a smooth silicon dioxide substrate by magnetron sputtering For a thick chromium layer, spin-coat photoresist AZ P4620 to a thickness of 5 μm on the chromium layer at 3500r / min, and then stand at 25°C for 18min, 55°C for 55min, 95°C for 4h, and 115°C for 50min. Baking, cooling to 25°C, covering the photoresist with a photomask for contact exposure, exposure time 55s, then immersing in pure water at 25°C for 4 minutes to develop, cleaning the surface 4 times with absolute ethanol, at 350g / L Copper plating is carried out in an electroplating solution of copper sulfate and 30mL / L sulfuric acid, at a current dens...

Embodiment 3

[0041] A high-strength integral molding micro-inductor preparation process, the high-strength integral molding micro-inductance preparation process mainly includes the following preparation steps:

[0042] (1) Coil production: under the conditions of pressure 3Pa, argon gas flow rate 20sccn, sputtering power 150w, sputtering rate 6nm / min, temperature 30°C, magnetron sputtering is sputtering 0.5μm on a smooth silicon dioxide substrate For a thick chromium layer, spin-coat photoresist AZ P4620 to a thickness of 6 μm at 4000 r / min on the chromium layer, and then stand at 30°C for 15 minutes, 60°C for 50 minutes, 100°C for 5 hours, and 120°C for 40 minutes. Baking, cooling to 30°C, covering the photoresist with a photomask for contact exposure, exposure time 50s, then immersing in pure water at 30°C for 3 minutes to develop, cleaning the surface with absolute ethanol 5 times, at 350g / L Copper plating is carried out in an electroplating solution of copper sulfate and 30mL / L sulfuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com