Metal-insulator-metal capacitor structure and fabrication method thereof

A technology of metal capacitors and manufacturing methods, applied in semiconductor/solid-state device manufacturing, semiconductor devices, circuits, etc., can solve the problems of large structure size of MIM capacitors and low requirements on photoresist morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Further description will be given below in conjunction with the accompanying drawings and embodiments.

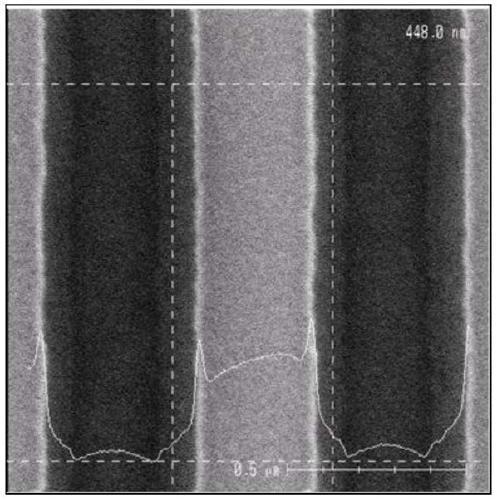

[0027] The method in the following embodiments can be used to fabricate a MIM capacitor ring, the size of which is less than 1 micron. The MIM capacitor ring is a ring-shaped MIM capacitor structure.

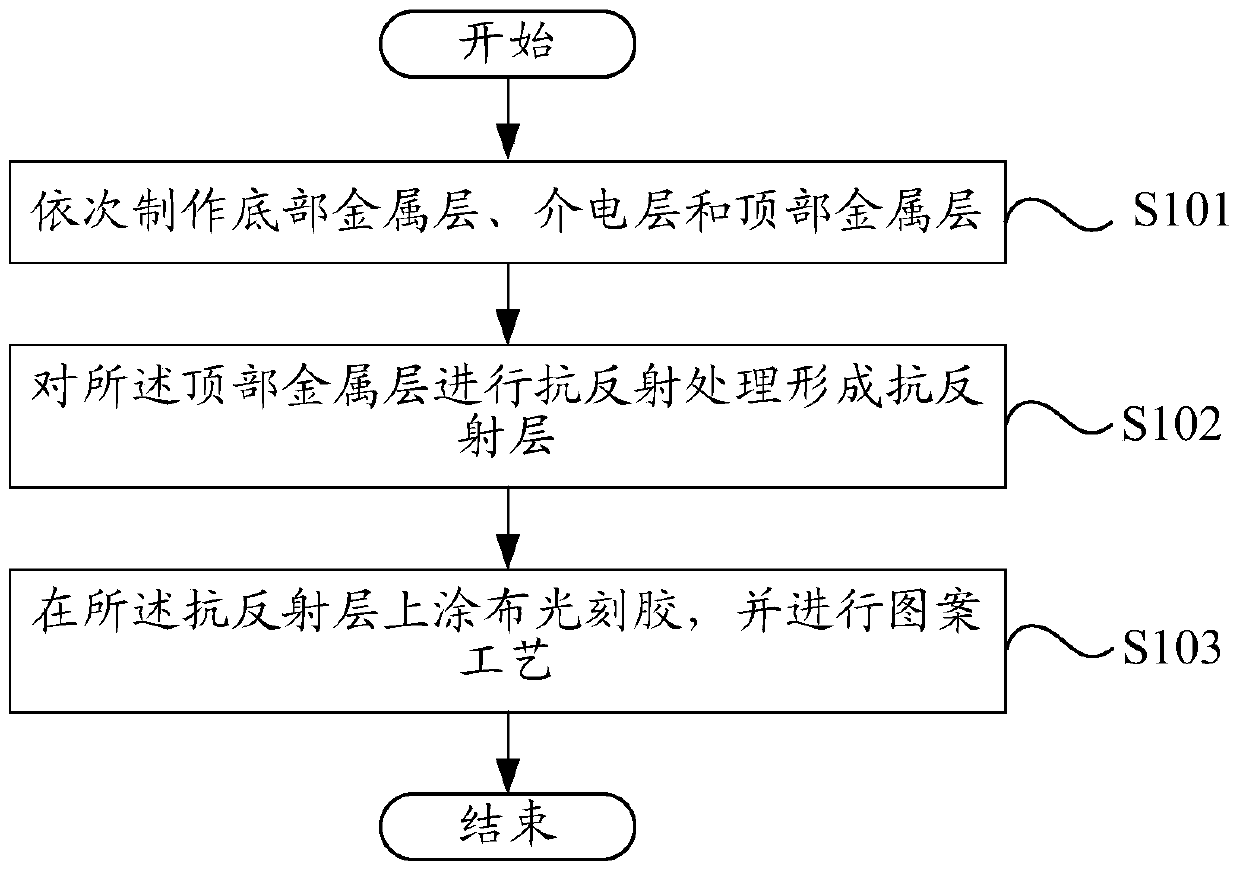

[0028] Such as figure 2 Shown is a flow chart of a fabrication method of a metal-insulator-metal capacitor structure according to an embodiment. The method includes the following steps.

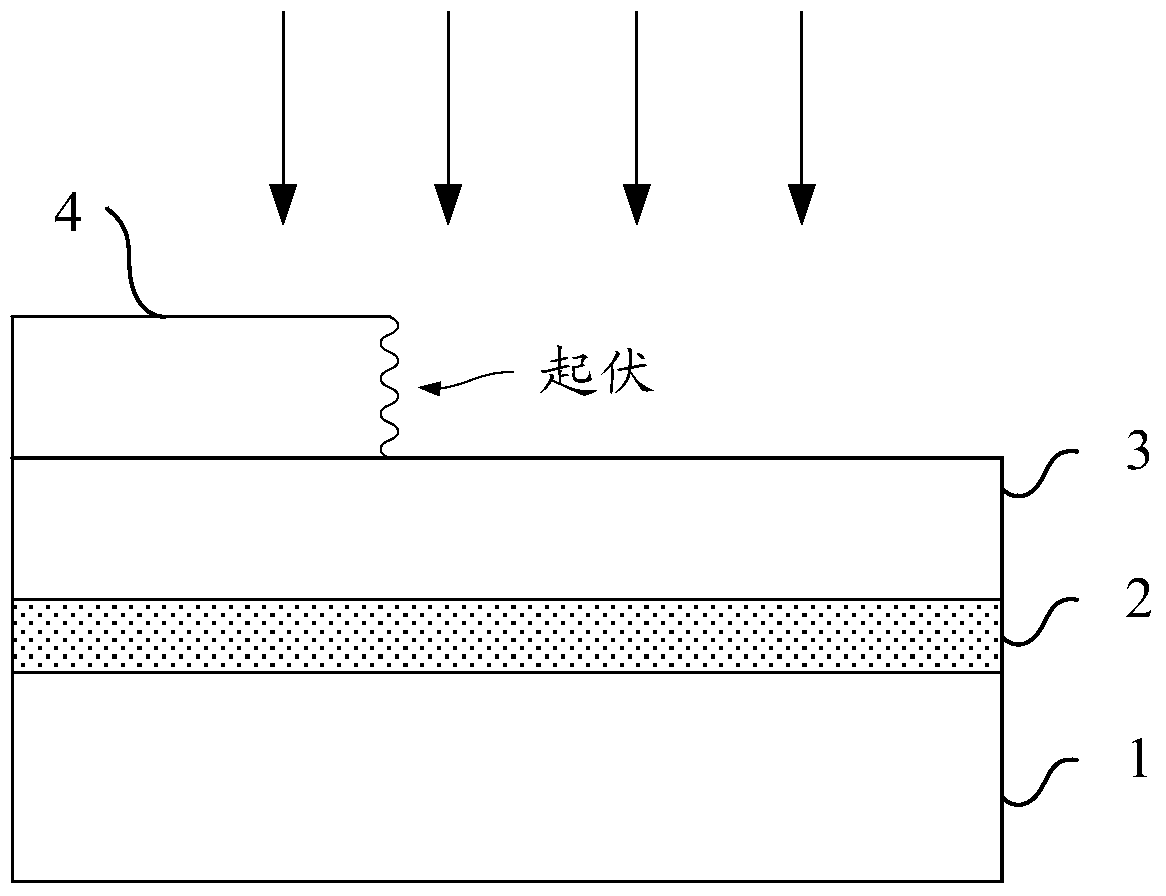

[0029] Step S101 : sequentially fabricate the bottom metal layer 100 , the dielectric layer 200 and the top metal layer 300 . The fabrication process of the bottom metal layer 100 , the dielectric layer 200 and the top metal layer 300 can all adopt a deposition process. Referring to FIG. 3 , the thickness of the bottom metal layer 100 is 3000-5000 angstroms, preferably 4000 angstroms; the thickness of the dielectric layer 200 is 300-400 angstroms, preferably 350 angstroms; the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com