1030nm sine type dielectric grating and manufacturing method thereof

A manufacturing method and a grating technology, applied in the field of optical components, can solve problems such as increasing the difficulty of grating processing, and achieve the effects of high etching process redundancy, easy manufacturing, and large redundancy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] first part

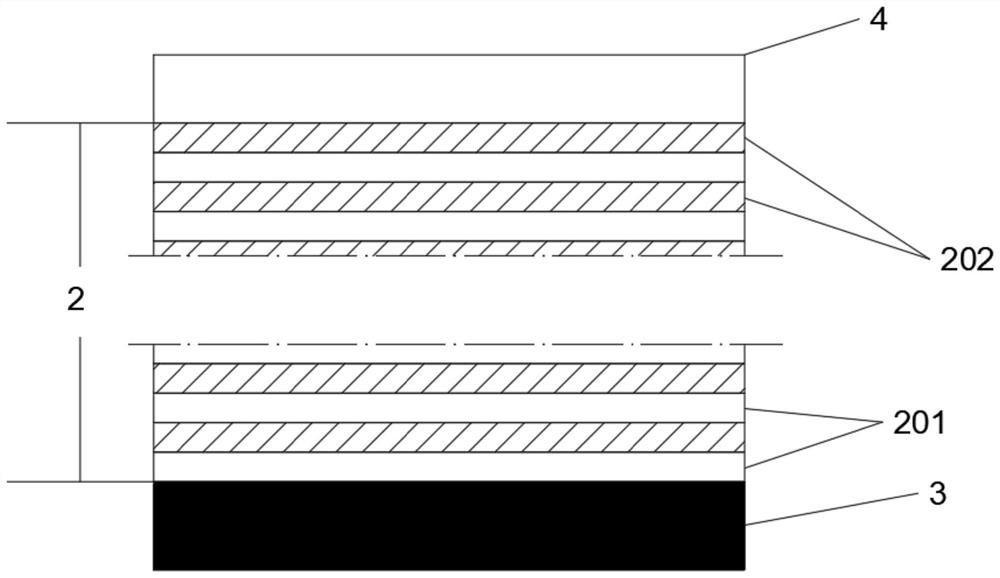

[0035] refer to Figure 4-5 , a 1030nm sinusoidal dielectric grating, comprising a top grating 1, a middle multilayer dielectric layer 2 and a substrate 3; the material of the top grating 1 is a high refractive index film material, and the middle multilayer dielectric layer 2 includes several alternately stacked The high refractive index material medium film layer 201 and the low refractive index material medium film layer 202, the material of the substrate 3 is a low refractive index material; the groove shape of the top grating 1 is sinusoidal. Compared with the existing all-dielectric grating, the grating contains only one film layer, and there is no need to precisely control the grating groove depth, duty cycle and groove shape during fabrication, which reduces the difficulty of grating fabrication.

[0036] Further,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com