A multi-source low-power low-temperature plasma polymerization coating device and method

A low-temperature plasma and coating device technology, applied in the field of plasma, can solve the problems of poor quality uniformity of batch products, uneven spatial distribution of plasma, and poor quality of polymer coatings, etc., to achieve good product quality uniformity , not easy to excessive damage, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

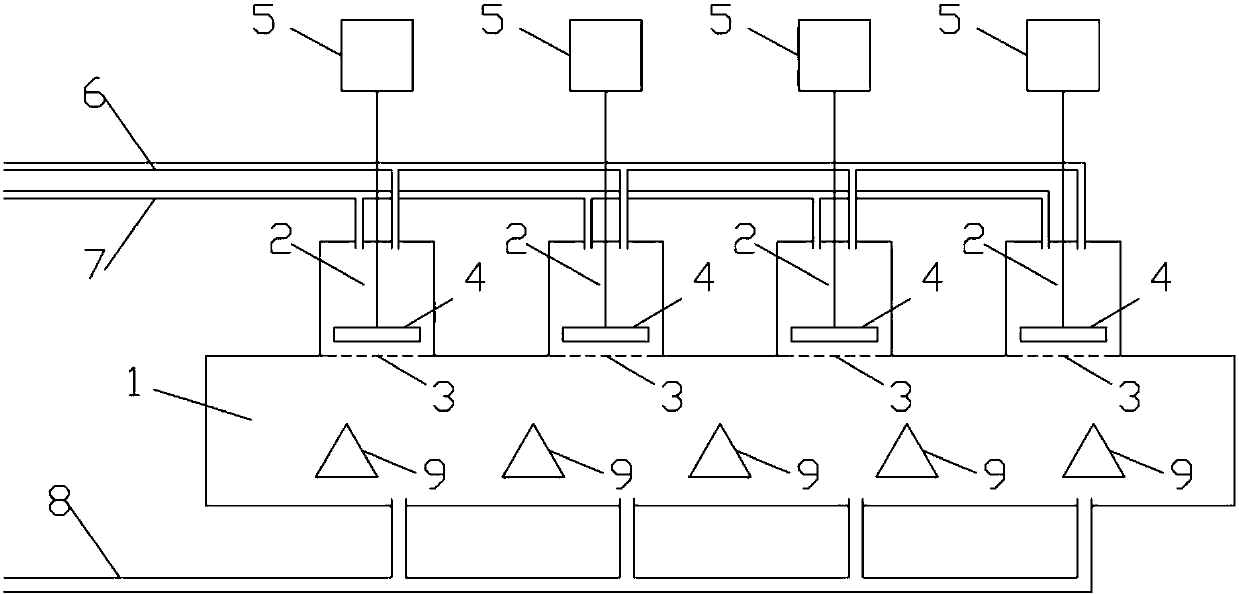

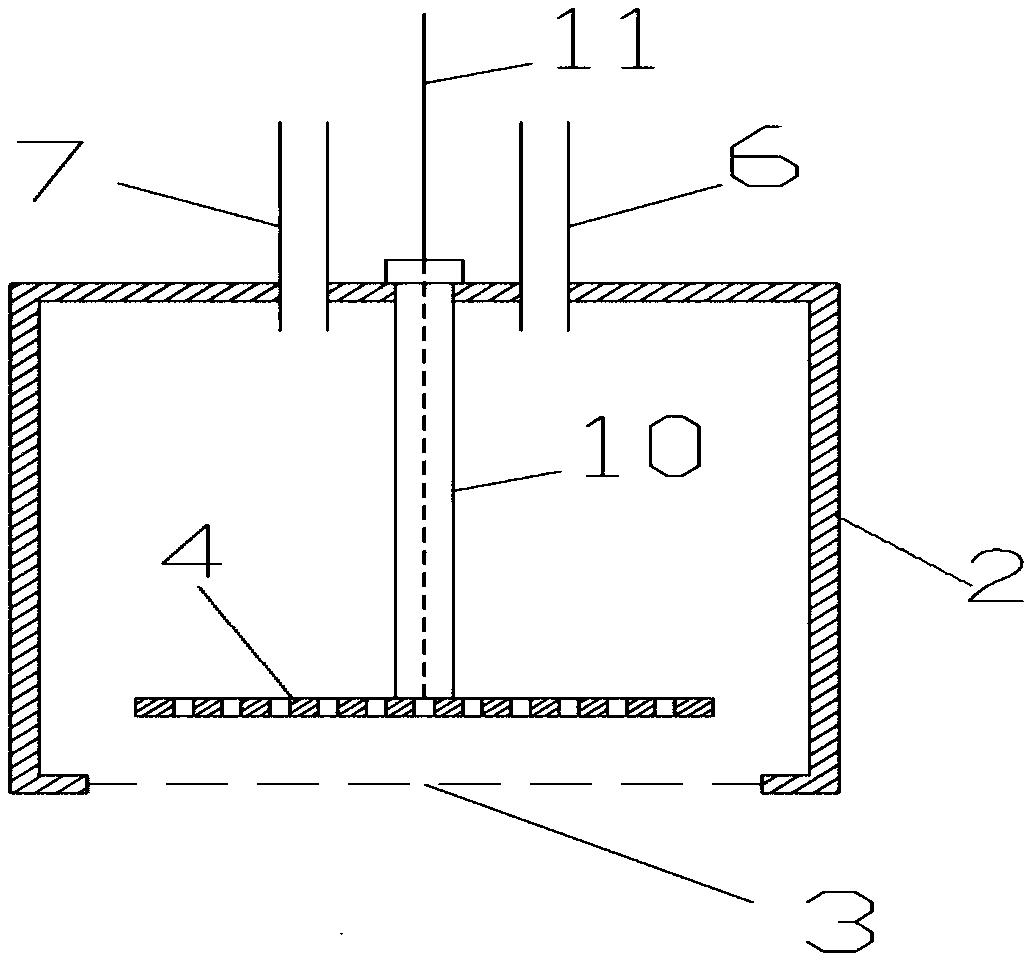

[0027] A multi-source low-power low-temperature plasma polymerization coating device. In the device, multiple discharge chambers are installed on the wall of the main vacuum chamber. The discharge chambers are cylindrical and made of metal. The diameter range is The depth is 150mm; the distance between the axes of adjacent discharge chambers is 70mm; a plane grounding grid is installed at the opening of the discharge chamber leading to the main vacuum chamber; a porous electrode plate is installed near the grid in the discharge chamber, and the porous electrode plate is Evenly distributed through holes, the diameter of the through holes is 1mm, and the hole spacing is 1mm; the porous electrode plate is parallel to the grid and the gap is less than 8mm; the porous electrode plate is fixed by an insulating bracket, connected to a low-power high-frequency power supply through a wire, and the power of the low-power high-frequency power supply The power is 5W, the frequency is 20kH...

Embodiment 2

[0029] A method for coating using the multi-source low-power low-temperature plasma polymerization coating device described in Embodiment 1, is characterized in that: mainly comprising the following steps:

[0030] (1) Place the substrate to be processed in the vacuum chamber, turn on the vacuum pump to pump the vacuum chamber to 1Pa;

[0031] (2), pass into carrier gas, make carrier gas enter discharge cavity and vacuum chamber through carrier gas pipeline, described carrier gas is argon, maintain the vacuum degree in vacuum chamber to be 30Pa; Pass into monomer vapor, make single The monomer vapor enters the vacuum chamber through the monomer vapor pipeline. The monomer vapor contains at least one unsaturated carbon-carbon bond, and one of the unsaturated carbon atoms does not contain a substituent. The structure of the monomer may contain a halogen functional group or Other functional groups, the halogen functional group is one or more of F, Cl, Br, I, and other functional ...

Embodiment 3

[0034] A multi-source low-power low-temperature plasma polymerization coating device. In the device, multiple discharge chambers are installed on the wall of the main vacuum chamber. The discharge chambers are cylindrical and made of metal. The diameter range is The depth is 30mm; the distance between the axes of adjacent discharge chambers is 400mm; a flat ground grid is installed at the opening of the discharge chamber leading to the main vacuum chamber; a porous electrode plate is installed near the grid in the discharge chamber, and the porous electrode plate is Evenly distributed through holes, the diameter of the through holes is 10mm, and the hole spacing is 10mm; the porous electrode plate is parallel to the grid and the gap is less than 8mm; the porous electrode plate is fixed by an insulating bracket, connected to a low-power high-frequency power supply through a wire, and the power of the low-power high-frequency power supply The power is 100W, and the frequency is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com