Fe-based cBN grinding wheel and preparation method thereof

A grinding wheel and iron-based binder technology, which is applied in the manufacture of tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problem of insufficient bonding force between diamond abrasives and binders, can not meet the processing requirements, and does not have high temperature resistance And other problems, to achieve the effect of improving the service life and processing efficiency, increasing the grinding speed, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

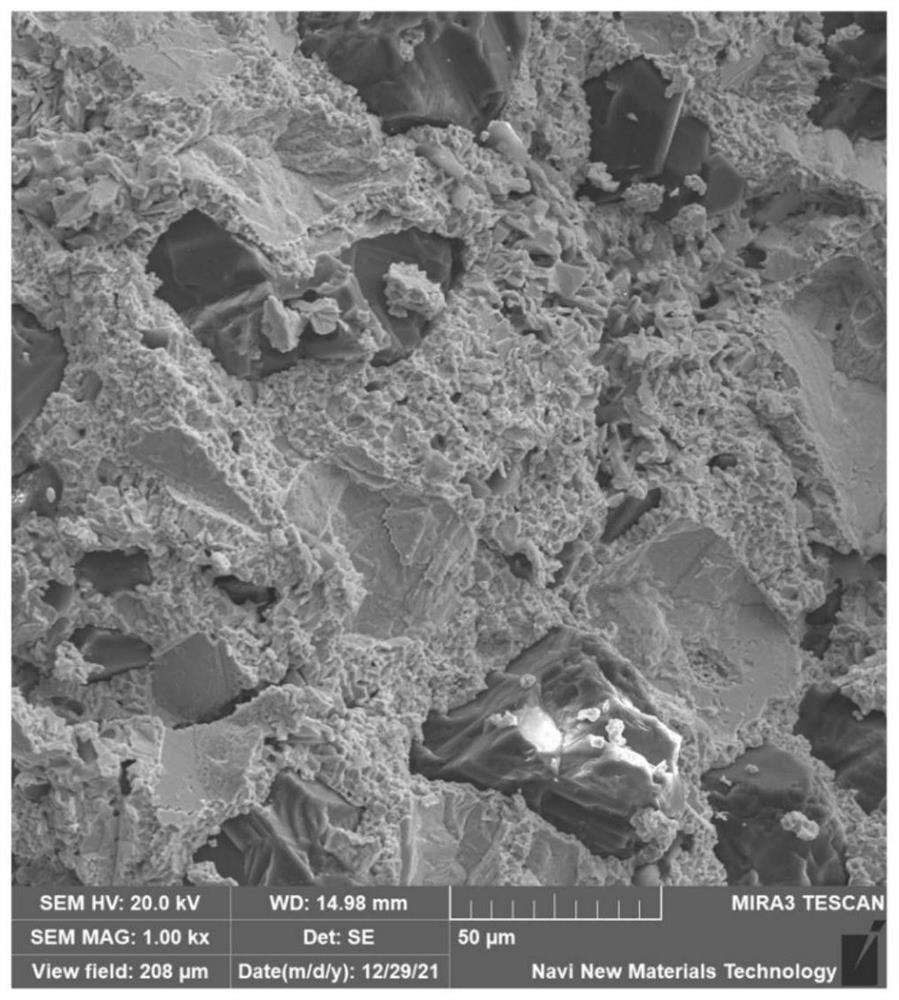

Image

Examples

Embodiment 1

[0034] Present embodiment takes following technical scheme:

[0035] An Fe-based cBN grinding wheel, wherein the cBN grinding wheel is prepared by combining the following parts according to the mass percentage: cBN abrasive: 15%, metal bond: 67%, auxiliary binder: 10%, pore-forming agent: 8 %, the sum of cBN abrasive, metal bond and auxiliary binder and pore-forming agent overall mass percentage is 100%; the mass percentage of described metal bond contains composition is: Fe powder: 60%, Co powder: 25% , Mo powder: 15%; Fe powder, the sum of Co powder and Mo powder mass percent is 100%; The porosity of emery wheel is 20%; The particle diameter of described cBN abrasive, Fe powder, Co powder and Mo powder is 200 μ m , purity ≥ 99%; the auxiliary binder is acrylic emulsion. The pore-forming agent is graphite, and the particle size of graphite is 80 μm

[0036] The basic dimensions of the grinding wheel are an outer diameter of 100 mm, an inner diameter of 80 mm, and a thicknes...

Embodiment 2

[0051] An Fe-based cBN grinding wheel, wherein the cBN grinding wheel is prepared by combining the following parts according to the mass percentage: cBN abrasive: 15%, metal bond: 67%, auxiliary binder: 10%, pore-forming agent: 8 %, the sum of cBN abrasive, metal bond and auxiliary binder and pore-forming agent overall mass percentage is 100%; the mass percentage of described metal bond contains composition is: Fe powder: 60%, W powder: 15% , Ni powder: 25%; Fe powder, the sum of W powder and Ni powder mass percentage is 100%; The porosity of grinding wheel is 25%; The particle diameter of described cBN abrasive, Fe powder, Co powder and Mo powder is 200 μ m , purity ≥ 99%; the auxiliary binder is acrylic emulsion. The pore-forming agent is graphite, and the particle size of graphite is 80 μm,

[0052] The basic dimensions of the grinding wheel are an outer diameter of 100 mm, an inner diameter of 80 mm, and a thickness of 8 mm.

[0053] The preparation method of the above-m...

Embodiment 3

[0067] An Fe-based cBN grinding wheel, wherein the cBN grinding wheel is prepared by combining the following parts according to the mass percentage: cBN abrasive: 15%, metal bond: 67%, auxiliary binder: 10%, pore-forming agent: 8 %, the sum of cBN abrasive, metal bond, auxiliary binder and pore-forming agent is 100%; the mass percentage of the metal bond contains: Fe powder: 50%, Co powder: 15% , W powder: 10%, Ni powder: 15%, Mo powder: 10%; Fe powder, Co powder, W powder, the sum of Ni powder and Mo powder mass percent is 100%; Grinding wheel porosity is 25%; The described The cBN abrasive, Fe powder, Co powder, W powder, Ni powder and Mo powder all have a particle size of 200 μm and a purity of ≥99%; the auxiliary binder is an acrylic emulsion. The pore forming agent is graphite. The particle size of graphite is 80 μm,

[0068] The basic dimensions of the grinding wheel are an outer diameter of 100 mm, an inner diameter of 80 mm, and a thickness of 8 mm.

[0069] The pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com