Phosphorus-free plastic refractory for casting and preparation method thereof

A plastic, mass percentage technology, applied in the field of cast steel and cast iron smelting, can solve the problems of low construction blank strength, hazards of molten iron and molten steel, short storage life, etc., achieve excellent high temperature volume stability, avoid pollution and damage, The effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

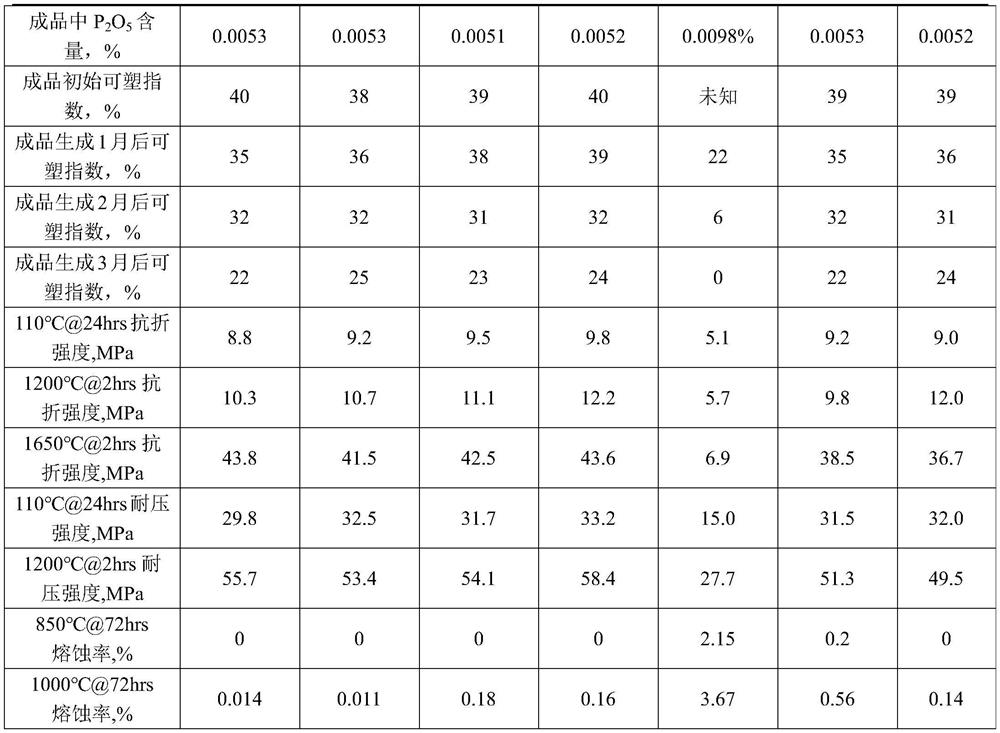

Embodiment 1

[0044] Example 1: A phosphorus-free plastic for casting and its preparation method

[0045] A phosphorus-free plastic for casting, calculated according to weight percentage, including the following: high-purity calcined tabular corundum 69%, high-purity low-sodium α-Al 2 o 3 11% fine powder, 6% fused cast zirconia corundum fine powder, 5% aluminum sulfate powder, 1.5% sodium silicate powder, 3% metallurgical coke powder, 3% 97% silicon fine powder and 1.5% metallic aluminum powder.

[0046] A preparation method of phosphorus-free plastic for casting, the method is as follows:

[0047] S1. Prepare high-purity calcined tabular alumina and high-purity low-sodium α-Al 2 o 3 Micropowder, fused cast zirconia corundum powder, aluminum sulfate powder, sodium silicate powder, metallurgical coke powder, 97% silicon micropowder, metal aluminum powder;

[0048] S2. High-purity calcined platy corundum raw material (0.045-1mm), high-purity and low-sodium α-Al 2 o 3 Add micropowder, fu...

Embodiment 2

[0051] Embodiment 2: A phosphorus-free plastic for casting, calculated according to weight percentage, including the following: 69% of high-purity calcined platy corundum, high-purity and low-sodium α-Al 2 o 3 12% fine powder, 7% fused cast zirconium corundum fine powder, 3% aluminum sulfate powder, 1.68% sodium silicate powder, 3% metallurgical coke powder, 3% 97% silicon fine powder and 1.32% metallic aluminum powder;

[0052] High-purity and low-sodium α-Al 2 o 3 Al in micropowder 2 o 3 The content is 99.8%, the sodium oxide content is less than 0.10%, and the particle size is 1.8-2.5μm; fused-cast zirconium corundum powder ZrO 2 The content is 31.5%, Al 2 o 3 content of 46.5%, SiO 2 ≤20.0%; Particle size ≥0.075mm; SiO in sodium silicate powder 2 The content is 65.0%, Na 2 The O content is 34.5%, and the modulus is 2.10.

[0053] According to the formula Calculate the addition of sodium silicate powder to be: 1.68%.

[0054] Wherein, w is the mass percent of so...

Embodiment 3

[0063] Embodiment 3: A phosphorus-free plastic for casting, calculated according to weight percentage, including the following: 70% high-purity calcined platy corundum, high-purity low-sodium α-Al 2 o 3 11% fine powder, 7% fused cast zirconia corundum powder, 3.3% aluminum sulfate powder, 1.20% sodium silicate powder, 3% metallurgical coke powder, 3% 97% silicon fine powder, and 1.5% metal aluminum powder.

[0064] High-purity and low-sodium α-Al 2 o 3 Al in micropowder 2 o 3 The content is 99.8%, the sodium oxide content is less than 0.10%, and the particle size is 1.8-2.5μm; fused-cast zirconium corundum powder ZrO 2 The content is 31.5%, Al 2 o 3 content of 46.5%, SiO 2 ≤20.0%; particle size ≥0.075mm; SiO in sodium silicate powder 2 The content is 65.0%, Na 2 The O content is 34.5%, and the modulus is 2.10.

[0065] According to the formula Calculate the addition of sodium silicate as 1.20%;

[0066] where T 1 is 1200°C, T 2 It is the maximum heating temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com