High-performance low-cost DFB laser epitaxial wafer and manufacturing method thereof

A DFB laser and manufacturing method technology, which is applied to lasers, laser parts, semiconductor lasers, etc., can solve the problem that the holographic exposure uniformity has a large influence on the optical path, the DFB laser yield has a large influence, and it is difficult to achieve large-size uniform gratings, etc. problem, to achieve the effect of suppressing the spatial hole burning effect, improving the side mode suppression ratio, and achieving excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

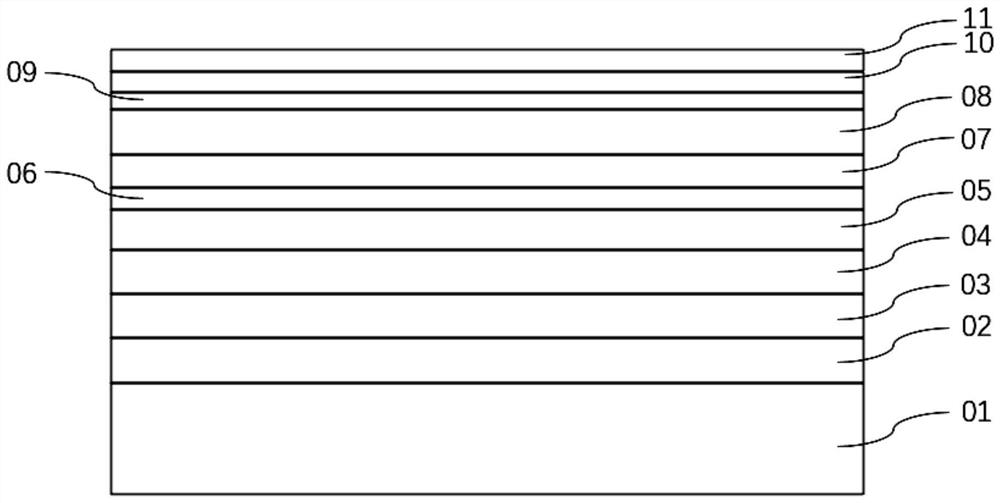

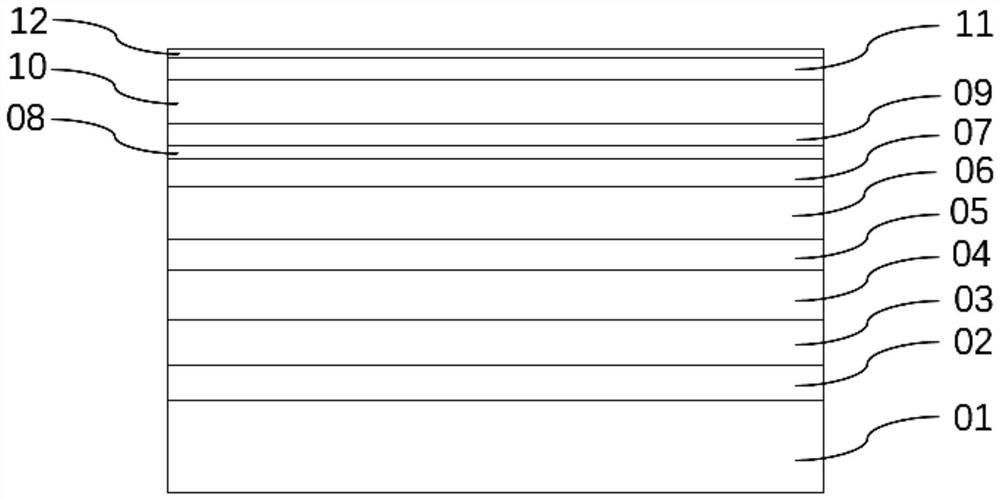

[0041] Example: such as figure 1 As shown, a high-performance and low-cost DFB laser epitaxial wafer, including a substrate 01, a lower buffer layer 02, a lower confinement layer 03, a lower waveguide layer 04, a quantum well 05, and an upper waveguide layer 06, which are sequentially stacked from bottom to top , upper confinement layer 07, upper buffer layer 08, corrosion barrier layer 09, cladding layer 10, grating fabrication layer 11, secondary epitaxial layer 14, barrier gradient layer and ohmic contact layer 17; grating fabrication layer 11 is divided into grating area and non-raster area. The area of the grating area is larger than the area of the non-grating area. The thickness of the grating fabrication layer 11 is 40 nm, and the grating region of the grating fabrication layer 11 has an asymmetric grating structure. The substrate 01 is an InP substrate, the lower buffer layer 02 is an N-InP layer, the lower confinement layer 03 is an N-AlInAs layer, the lower wa...

specific Embodiment

[0051] With a conductivity of 2-8x10 18 cm -2 InP is used as the growth substrate and put into the MOCVD system for growth. The reaction chamber pressure was 50mbar, the growth temperature was 670°C, and the 2 As carrier gas, trimethylindium (TMIn), trimethylgallium (TMGa), trimethylaluminum (TMAl), diethylzinc (DeZn), silane (SiH 4 ), arsine (AsH 3 ) and phosphine (PH 3 ) etc. as the reaction source gas, sequentially grow N-InP buffer layer, N-AlInAs confinement layer, non-doped AlGaInAs lower waveguide layer with graded refractive index, 6-period AlGaInAs quantum wells, non-doped graded refractive index AlGaInAs upper waveguide layer, non-doped AlInAs confinement layer, P-InP transition layer, InGaAsP corrosion barrier layer with wavelength of 1100nm, InP cladding layer and InGaAsP grating fabrication layer with wavelength of 1100nm. The thickness of the InGaAsP grating fabrication layer is 40 nm.

[0052] Spin-coat a photoresist mask on the surface of the above-mentio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com