Manufacture method of distributed feedback laser for restraining space hole-burning effect

A distributed feedback and spatial hole-burning technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of high price, harsh and complex grating process requirements, suppress the spatial hole-burning effect, and improve single-mode stability. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

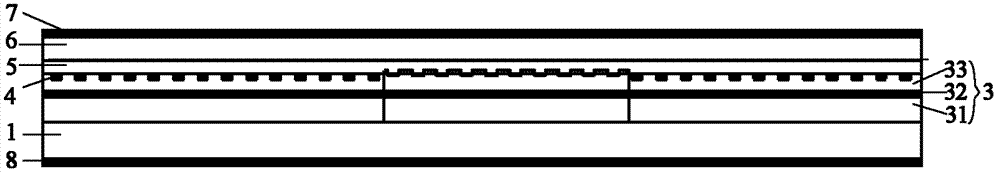

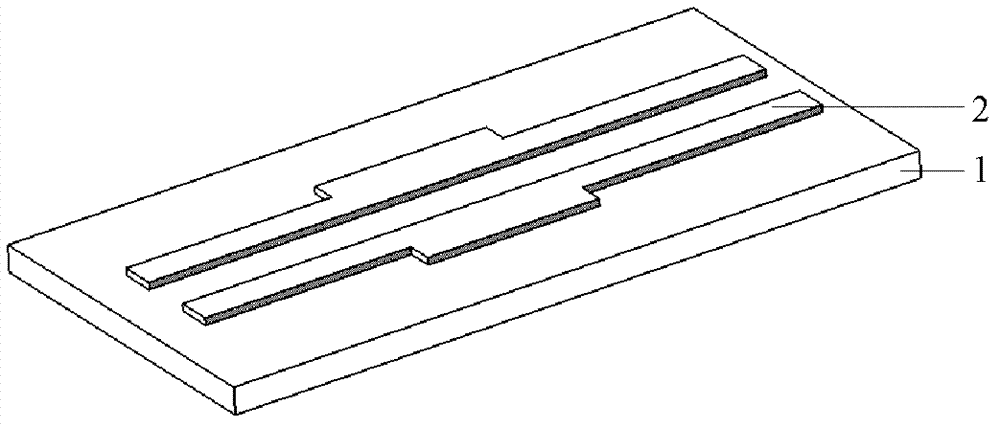

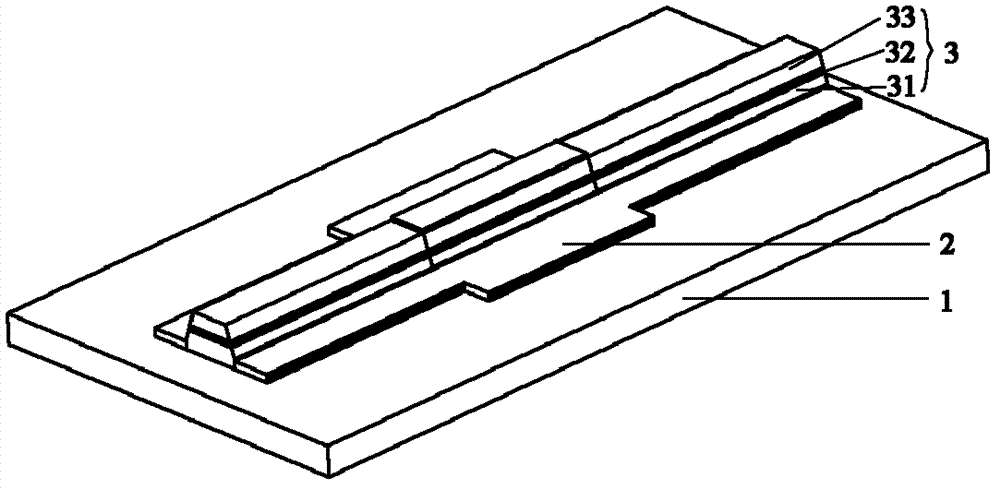

[0043] please refer again figure 1 , and combined with reference to shown in Figure 2, a method for manufacturing a distributed feedback laser that suppresses the spatial hole-burning effect on an n-type InP substrate includes the following steps:

[0044] Select an n-type (100) plane InP substrate 1 with a doping concentration of 5×10 17 -5×10 18 cm -3 ; Utilize conventional plasma-enhanced vapor deposition method to grow SiO with a thickness of 30-300nm on the substrate 1 2 or Si 3 N 4 For the dielectric mask, the dielectric mask pattern 2 is formed on the surface of the dielectric mask by using conventional mask photolithography technology, wherein the dielectric mask pattern 2 appears in pairs, and the width of the mask strip in the middle section is greater than that of the mask strips on both sides. width;

[0045] growing the lower waveguide layer 31, the InGaAsP core layer 32 and the upper waveguide layer 33 sequentially on the substrate 1 with the dielectric mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com