Chromium-free passivation solution as well as preparation method and application thereof

A chromium-free passivation and reaction technology, applied in the field of materials, can solve the problems of the technical application limitation of chromium-free passivation agent for steel, uneven film formation on the metal surface, poor adhesion of the passivation film, etc., and achieve excellent storage stability. And the effect of stability in use, excellent adhesion, and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

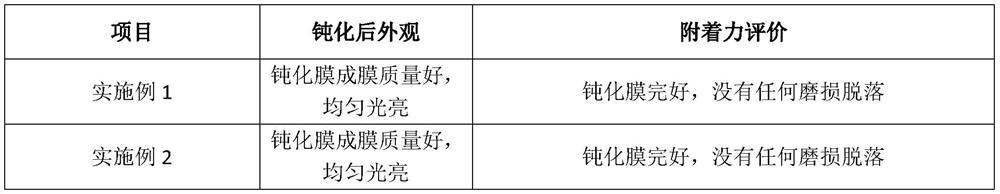

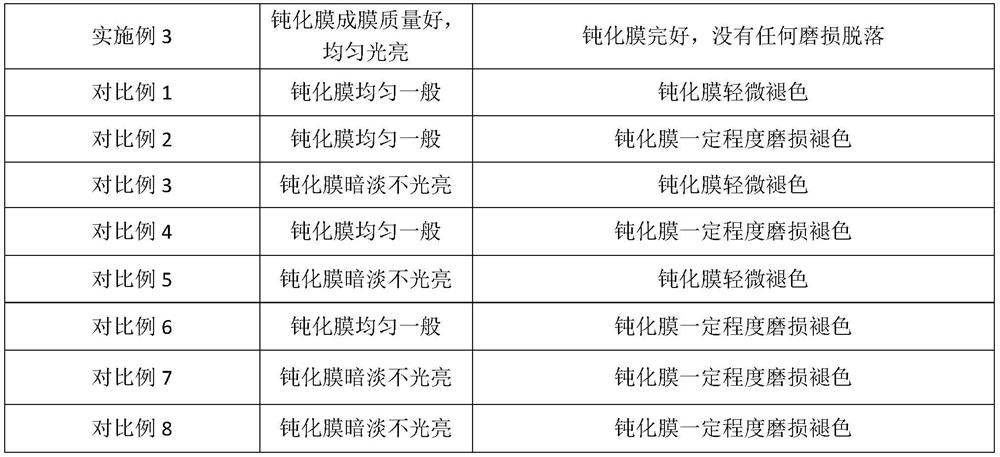

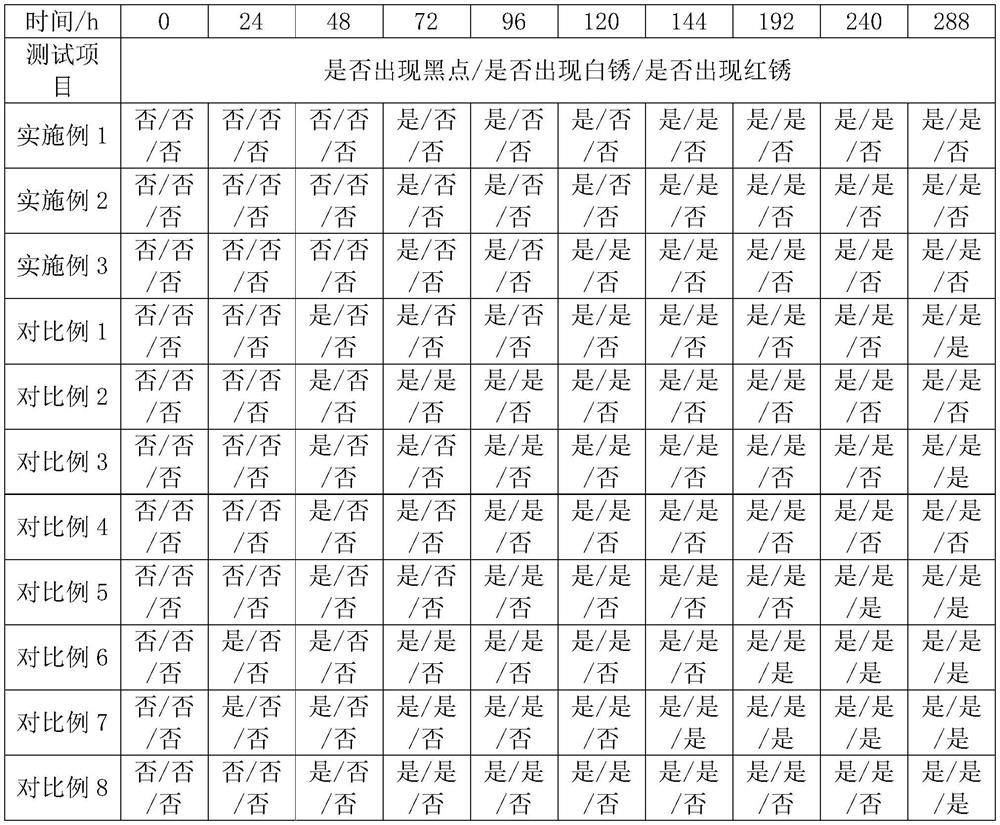

Examples

Embodiment 1

[0056] The chromium-free passivation solution in this example includes the following components by weight: 2 parts of silane coupling agent, 2 parts of tetraalkoxysilane, 6 parts of lithium polysilicate, 10 parts of cationic urethane resin emulsion , 5 parts of titanate and / or titanium-containing compound, 4 parts of corrosion inhibitor, 6 parts of chelating agent, 100 parts of distilled water; the silane coupling agent is HYDROSIL2776 produced by Guangzhou Jianyi Chemical Import and Export Co., Ltd.; cationic urethane The ester resin is ethyl formate resin containing primary amino groups; the titanate and / or titanium-containing compound is ammonium fluorotitanate; the corrosion inhibitor is benzotriazole; and the chelating agent is nitrilotriacetic acid.

[0057] The chromium-free passivation solution in this example is prepared by the following preparation method, comprising the following steps:

[0058] (1) Add 100 parts of distilled water into the container and heat it to ...

Embodiment 2

[0063] The chromium-free passivation solution in this example includes the following components by weight: 3 parts of silane coupling agent, 3 parts of tetraalkoxysilane, 4 parts of lithium polysilicate, 12 parts of cationic urethane resin emulsion , 4 parts of titanate, 3 parts of corrosion inhibitor, 5 parts of chelating agent, 100 parts of distilled water; the silane coupling agent is HYDROSIL2776 produced by Guangzhou Jianyi Chemical Import and Export Co., Ltd.; the cationic urethane resin emulsion is Secondary amino ethyl formate resin; titanate is potassium fluotitanate; corrosion inhibitor is rosin-based imidazoline; chelating agent is sodium edetate.

Embodiment 3

[0065] The chromium-free passivation solution in this example includes the following components by weight: 2 parts of silane coupling agent, 4 parts of tetraalkoxysilane, 2 parts of lithium polysilicate, 8 parts of cationic urethane resin emulsion , 5 parts of titanate, 6 parts of corrosion inhibitor, 3 parts of chelating agent, 100 parts of distilled water; the silane coupling agent is HYDROSIL2776 produced by Guangzhou Jianyi Chemical Import and Export Co., Ltd.; the cationic urethane resin emulsion is Secondary amino ethyl formate resin; titanate is potassium titanate; corrosion inhibitor is thioureidoimidazole; chelating agent is ammonium citrate.

[0066] The preparation method of the chromium-free passivation solution in Example 2 and Example 3 is prepared with reference to the preparation method of the chromium-free passivation solution in Example 1.

[0067] The chromium-free passivation solution in Examples 1 to 3 of the present invention is suitable for use as a pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com