Bisphenol A derivative and preparation method thereof and application of bisphenol A derivative in photoetching

A photolithography and photoresist technology, applied in the field of photolithography, can solve the problems of increasing the diffusion of photoacid generators, unable to overcome resolution, performance degradation, etc., and achieve excellent mechanical strength and improve the effect of pattern collapse behavior.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The synthetic preparation of embodiment 1 epoxy compound (I-a)

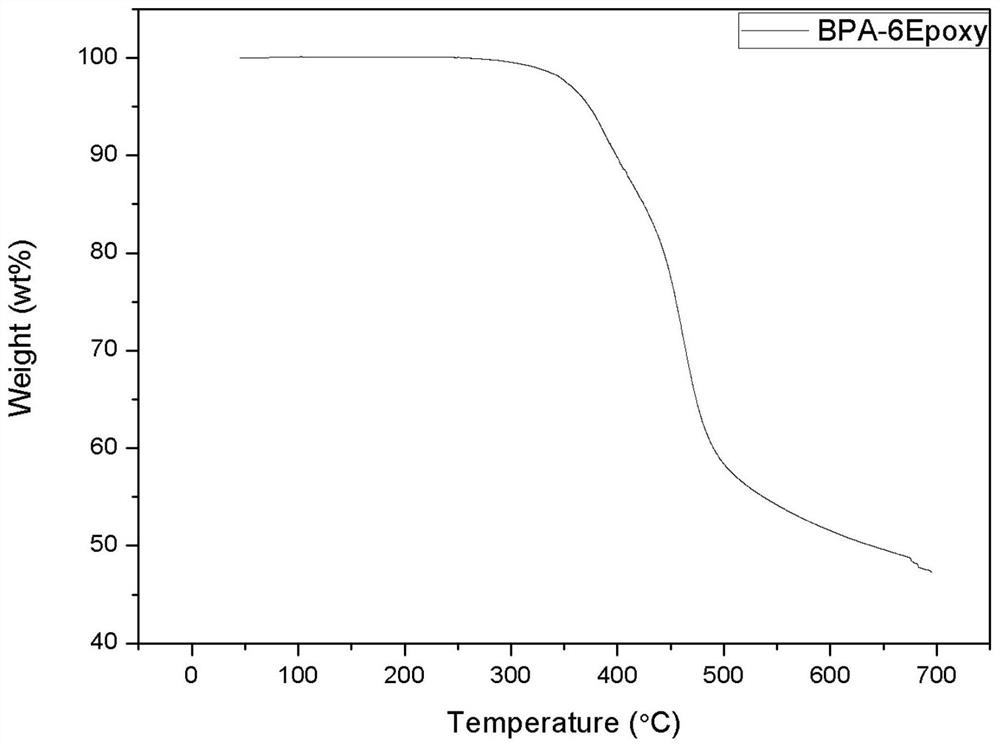

[0051] Weigh 5.98g (10mmol) of BPA-6OH, 21.50g (66mmol) of Cs 2 CO 3 , into a 150ml three-necked flask in turn, measure 7ml (70mmol) of epibromohydrin, and then add 15ml of N-methylpyrrolidone, and stir at reflux at 50-55°C for 18-24h. After the reaction, the reaction mixture was diluted with chloroform, then washed three times with deionized water, and washed with anhydrous Na 2 CO 3 After drying, it was exchanged in a methanol solvent and dried in vacuum at 60°C to obtain 5.05 g of a light yellow solid epoxy compound (I-a) with a fully protected epoxy group, with a yield of 54%. MALDI-TOF (C 57 h 56 o 12 ), m / z: 932.376. Its TGA diagram is as follows figure 1 shown by figure 1 It can be seen that it has high thermal stability, and only loses 5% of its mass around 370°C.

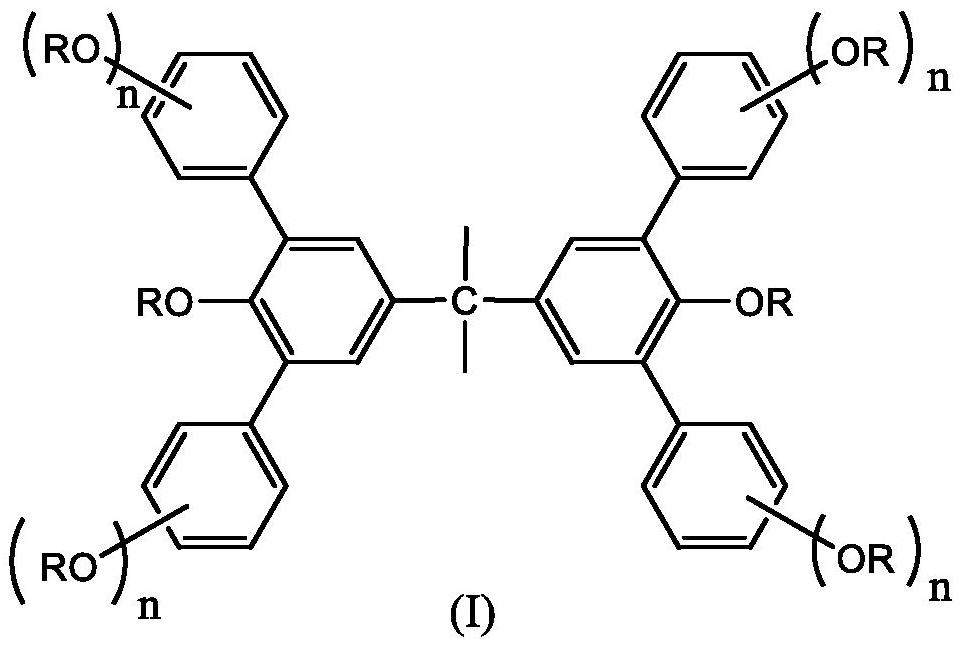

[0052] Wherein, the structure of raw material BPA-6OH is:

[0053]

[0054] The structure of product epoxy compound (I-a...

Embodiment 2

[0056] The preparation of embodiment 2 containing epoxy compound (I-a) negative photoresist composition

[0057] Weigh 300 mg of the epoxy compound (I-a) which is fully protected by the epoxy group prepared in Example 1, 22.5 mg of the photoacid generator N-hydroxynaphthalimide trifluoromethanesulfonate, and measure the photoresist 10 ml of solvent propylene glycol monomethyl ether acetate (PGMEA) was prepared into a photoresist solution, and after ultrasonic treatment for half an hour, it was filtered three times with a 0.20 μm polytetrafluoroethylene film to prepare a negative photoresist composition.

Embodiment 3

[0058] Embodiment 3 contains the lithography performance of test epoxy compound (I-a) negative photoresist composition

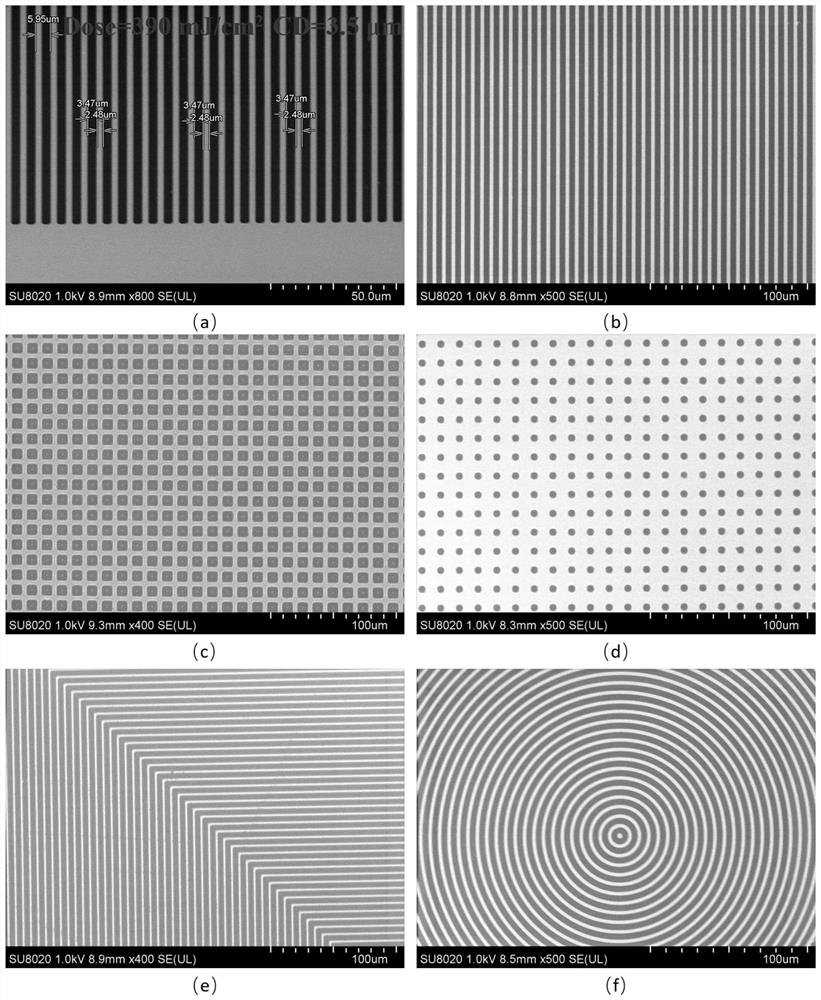

[0059] Prepare a negative photoresist composition of 30mg / ml according to Example 2, select an untreated blank silicon wafer, set the spin coating parameters to 3000rpm / 90s, and set the pre-baking parameters to 80°C / 120s, and measure the film with an ellipsometer The thickness is about 50nm. The 365nm wavelength UV lithography was carried out using a front-side alignment UV lithography machine from ABM Company in the United States. The exposure time was set to 30s, the post-baking parameter was 90°C / 120s, the developing parameter was methyl isobutyl ketone / 30s, and the washing parameter was isopropyl Alcohol / 30s. After exposure, use a Hitachi 8020 scanning electron microscope to collect SEM images. The specific photolithography results are as follows figure 2 shown. Depend on figure 2 It can be seen that the obtained photoresist composition has higher ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com