Negative electrode material, preparation method and application thereof

A negative electrode material and negative electrode technology, applied in the field of negative electrode material and its preparation, can solve the problems of large irreversible capacity, uneven distribution of slurry, and reduce material stability, and achieve the improvement of lithium ion transmission speed, elimination of polarization effect, and method. Simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037]According to another aspect of the present invention, the present invention also relates to the preparation method of described negative electrode material, comprises the following steps:

[0038] Mixing the negative electrode base material, stearic acid and dispersant;

[0039] The negative electrode substrate is a core-shell structure, wherein the inner core includes Si and SiO x , 0.5≤x≤2; the middle layer includes a lithium silicate compound; the shell layer includes carbon.

[0040] A stable lithium-supplementing silicon-oxygen material can be obtained after being uniformly dispersed by a mechanical mixing method.

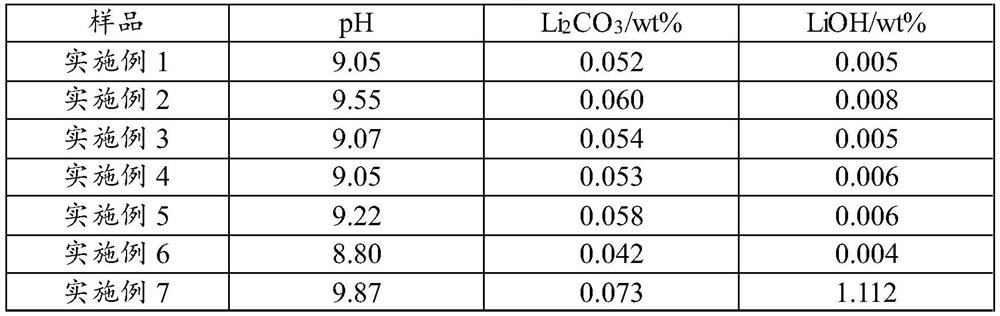

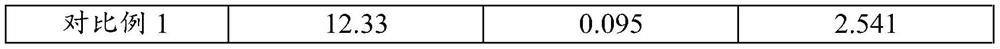

[0041] Stearic acid is esterified with partially reversible lithium silicate and residual alkali LiOH in the negative electrode substrate at room temperature. The resulting reaction product has certain elasticity and can inhibit the volume expansion of the internal silicon oxide particles together with the carbon coating layer. , to ensure the integrit...

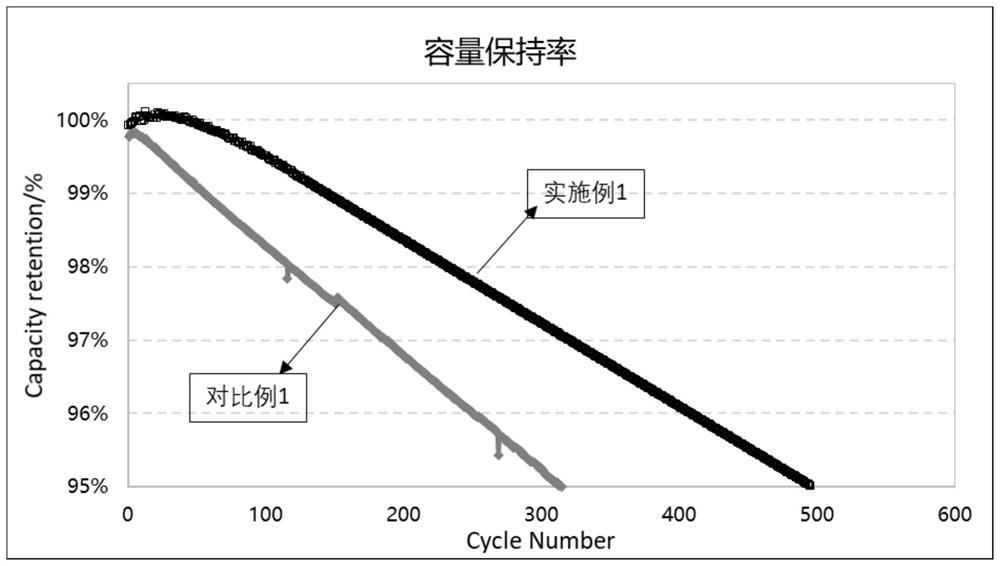

Embodiment 1

[0070] A preparation method of negative electrode material, comprising the following steps:

[0071] (1) Sample SiO after ball milling x Transfer to a tube furnace, pass through Ar to remove the air in the tube, heat to 700°C at a heating rate of 5°C / min, and then maintain a constant temperature for 2 hours; after the heat preservation is completed, change Ar to acetylene gas for CVD deposition, and control the flow rate of acetylene to make the sample The carbon coating content is 3wt%; then the atmosphere in the furnace is changed to Ar, and Si / SiO can be obtained by natural cooling x @C composite material (silicon-oxygen composite material coated with carbon, the same below), denoted as sample S1;

[0072] (2) 50g S1 sample and 10g Li 2 Mix the O powder evenly, transfer it to a tube furnace, pass it into Ar to remove the air in the tube, raise the temperature at 5°C / min to 400°C and keep it for 1 hour to complete the thermal doping lithium supplementation, and obtain lith...

Embodiment 2

[0075] A preparation method of negative electrode material, comprising the following steps:

[0076] (1) Sample SiO after ball milling x Transfer to a tube furnace, pass through Ar to remove the air in the tube, heat to 700°C at a heating rate of 5°C / min, and then maintain a constant temperature for 2 hours; after the heat preservation is completed, change Ar to acetylene gas for CVD deposition, and control the flow rate of acetylene to make the sample The carbon coating content is 1wt%; then the atmosphere in the furnace is changed to Ar, and Si / SiO can be obtained by natural cooling x @C composite material, denoted as sample S1;

[0077] (2) 50g S1 sample and 10g Li 2 Mix the O powder evenly, transfer it to a tube furnace, pass it into Ar to remove the air in the tube, raise the temperature at 5°C / min to 400°C and keep it for 1 hour to complete the thermal doping lithium supplementation, and obtain lithium supplementation silicon oxide material after cooling with the furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com