Corrosion-resistant aluminum alloy composite coating as well as preparation method and application thereof

A composite coating and aluminum alloy technology, which is applied in the field of metal corrosion resistance, can solve the problems that the anti-corrosion and self-repairing effects of the aluminum alloy matrix cannot be completely replaced, the metal matrix has weak bonding force, and the human body and the environment are harmful, so as to inhibit corrosion Response, long-lasting protection, less time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

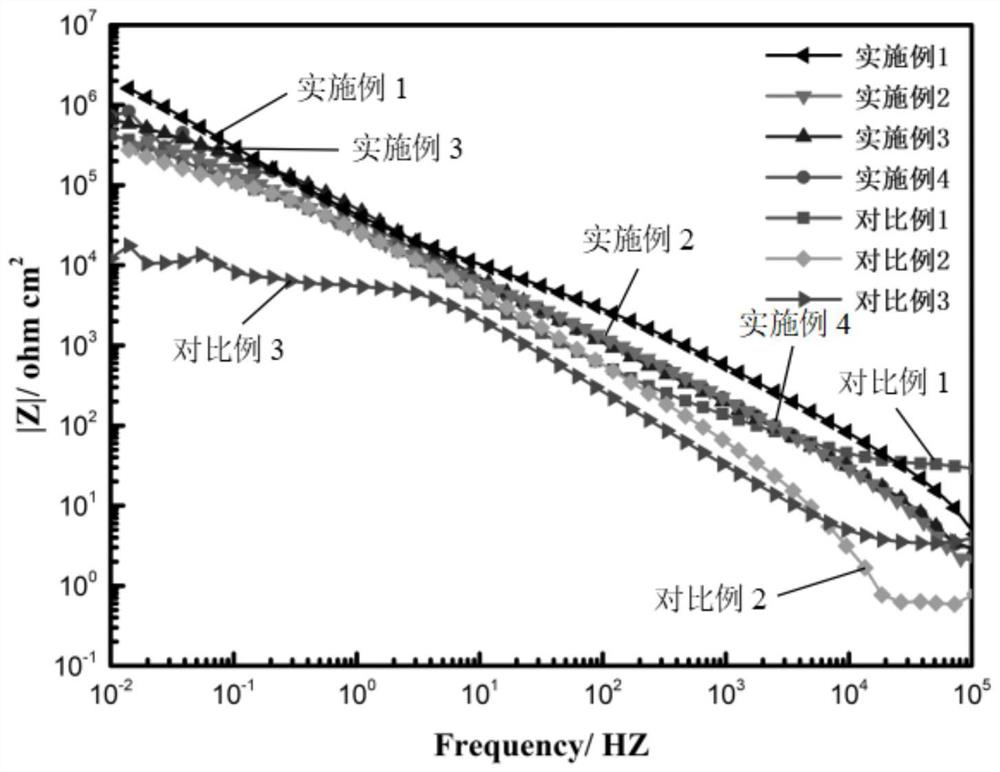

Embodiment 1

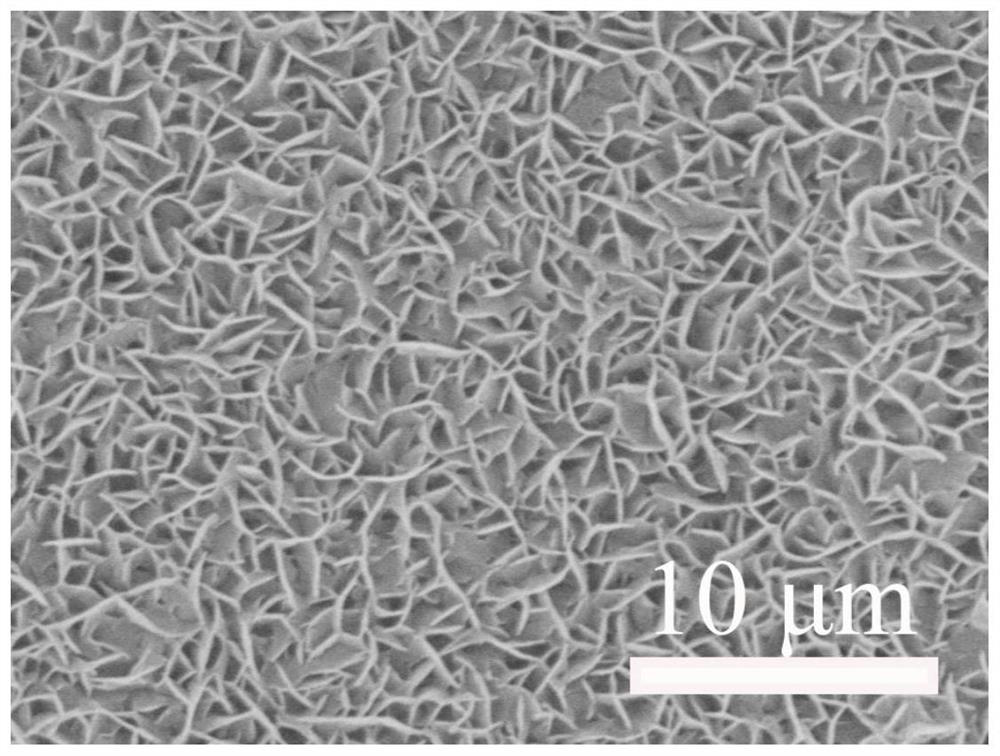

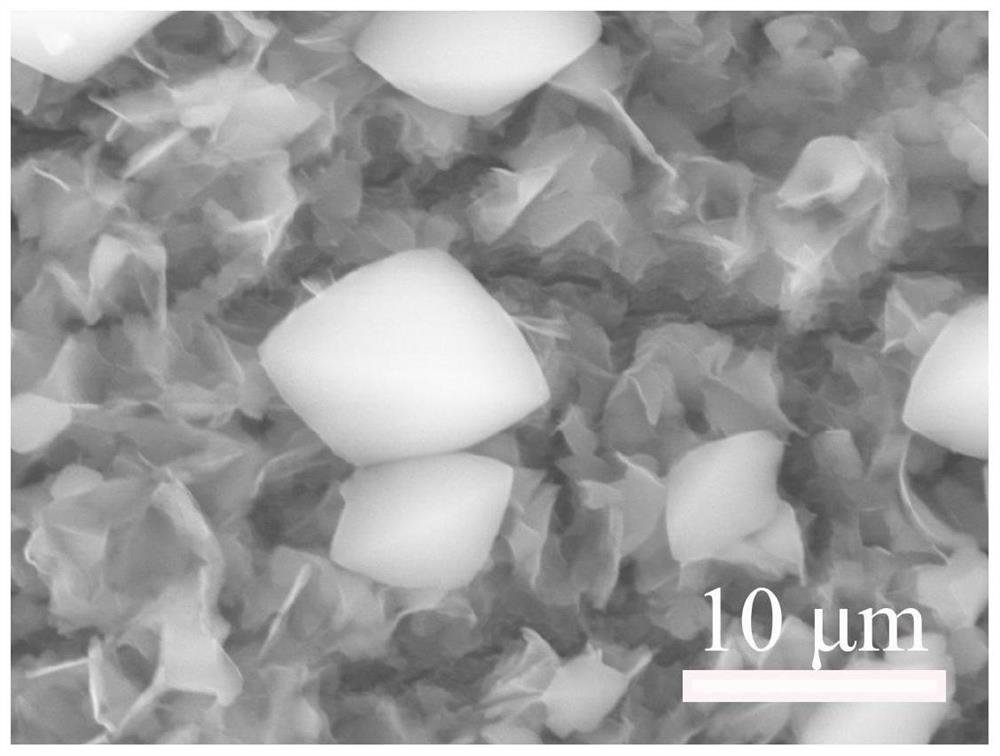

[0049] An aluminum alloy composite coating, which includes a lithium-aluminum layered double metal hydroxide film layer and a metal organic framework material layer from the inside to the outside; and the interlayer of the lithium-aluminum layered double metal hydroxide film layer contains an amino acid buffer etchant.

[0050] Among them: the components of the conversion solution for preparing the lithium-aluminum layered double metal hydroxide film layer include: methionine 2.1g / L, lithium hydroxide 2.6g / L, lithium nitrate 8g / L; preparation of metal organic framework materials The conversion solution of the layer includes: Trimellitic acid 0.6g / L, the mass ratio of ethanol and water in the solvent is 3:1; the thickness of the aluminum alloy composite coating is 100nm.

[0051] A method for preparing an aluminum alloy composite coating, comprising the following steps:

[0052] (1) At room temperature, immerse the 6063 aluminum alloy sheet in an alkaline solution mixed with 4...

Embodiment 2

[0056] An aluminum alloy composite coating, which includes a lithium-aluminum layered double metal hydroxide film layer and a metal organic framework material layer from the inside to the outside; and the interlayer of the lithium-aluminum layered double metal hydroxide film layer contains an amino acid buffer etchant.

[0057] Among them: the components of the conversion solution for preparing the lithium-aluminum layered double metal hydroxide film layer include: methionine 2.2g / L, lithium hydroxide 2.5g / L, lithium nitrate 10g / L; preparation of metal organic framework materials The conversion liquid of the layer includes: trimesic acid 0.5g / L, the mass ratio of ethanol and water in the solvent is 3:1; the thickness of the aluminum alloy composite coating is 150nm.

[0058] A method for preparing an aluminum alloy composite coating, comprising the following steps:

[0059] (1) At room temperature, immerse the 6063 aluminum alloy sheet in an alkaline solution mixed with 40g / L...

Embodiment 3

[0063] An aluminum alloy composite coating, which includes a lithium-aluminum layered double metal hydroxide film layer and a metal organic framework material layer from the inside to the outside; and the interlayer of the lithium-aluminum layered double metal hydroxide film layer contains an amino acid buffer etchant.

[0064] Wherein: the components of the conversion liquid for preparing the lithium-aluminum layered double metal hydroxide film layer include: threonine 2.5g / L, lithium hydroxide 3g / L, lithium nitrate 7g / L; The conversion solution includes: trimesic acid 0.7g / L, the mass ratio of ethanol to water in the solvent is 3:1; the thickness of the aluminum alloy composite coating is 200nm.

[0065] A method for preparing an aluminum alloy composite coating, comprising the following steps:

[0066] (1) At room temperature, immerse the 6063 aluminum alloy sheet in an alkaline solution mixed with 40g / L sodium hydroxide and 0.1g / L sodium dodecyl sulfate, take it out after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com