Method for preparing ceramic composite membrane of proton conduction type solid oxide pool through water-based tape casting

A solid oxide and ceramic composite membrane technology, which is applied in fuel cells, final product manufacturing, electrochemical generators, etc., can solve the problem of unstable reaction between barium cerate and barium zirconate proton conductors, low electrolyte density, and electrical conductivity. Low-level problems, to achieve the effect of no pollution to the environment, good uniformity, and high energy conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The specific preparation method comprises the following process steps:

[0039] Step 1: Proportionally mix the first ceramic powder mixture, deionized water, starch pore-forming agent, polyacrylic acid dispersant, diluted ammonia water, polyvinyl alcohol binder, polyethylene glycol-200 and glycerin plasticizer, 1 - Octanol defoamer and 2,4,7,9-tetramethyl-5-decyne-4,7-diol surfactant were added into a ball mill tank, and ball milling was carried out to mix uniformly to obtain a hydrogen electrode slurry. The first ceramic powder mixture includes nickel oxide and proton conductor ceramic powder;

[0040] The mass ratio of each component is: the first ceramic powder mixture: deionized water: dispersant: binder: plasticizer: surfactant: defoamer=1: (0.5~1.6): (0.015~0.03 ):(0.03~0.1):(0.06~0.3):(0.01~0.05):(0.005~0.02), the mass ratio of nickel oxide and proton conductor ceramic powder in the first ceramic powder mixture is 6:4,

[0041] In another solution, the hydrogen...

Embodiment 1

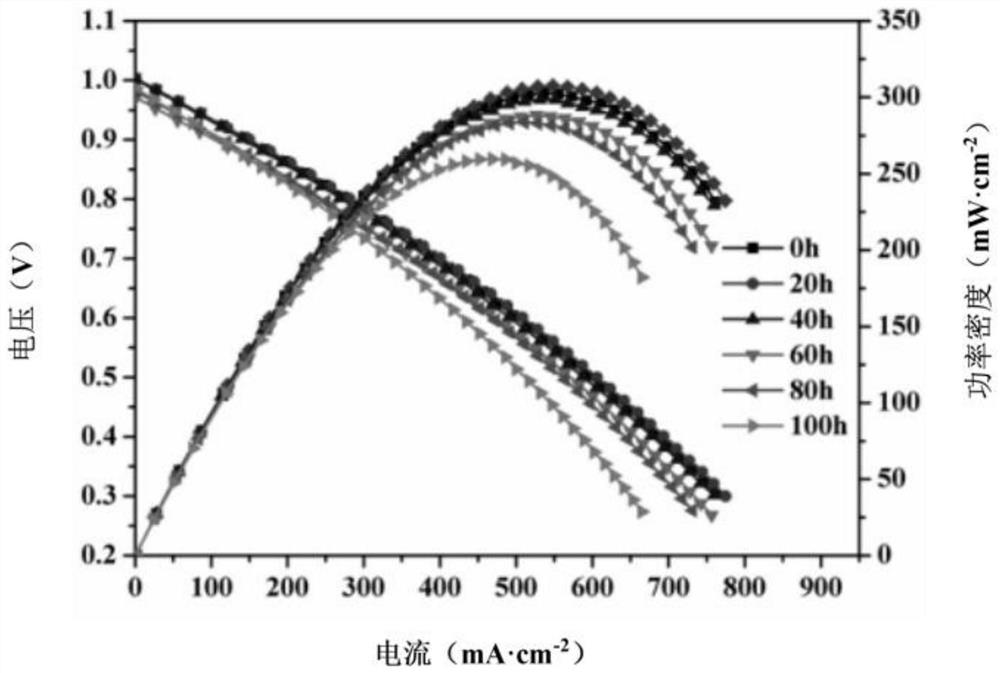

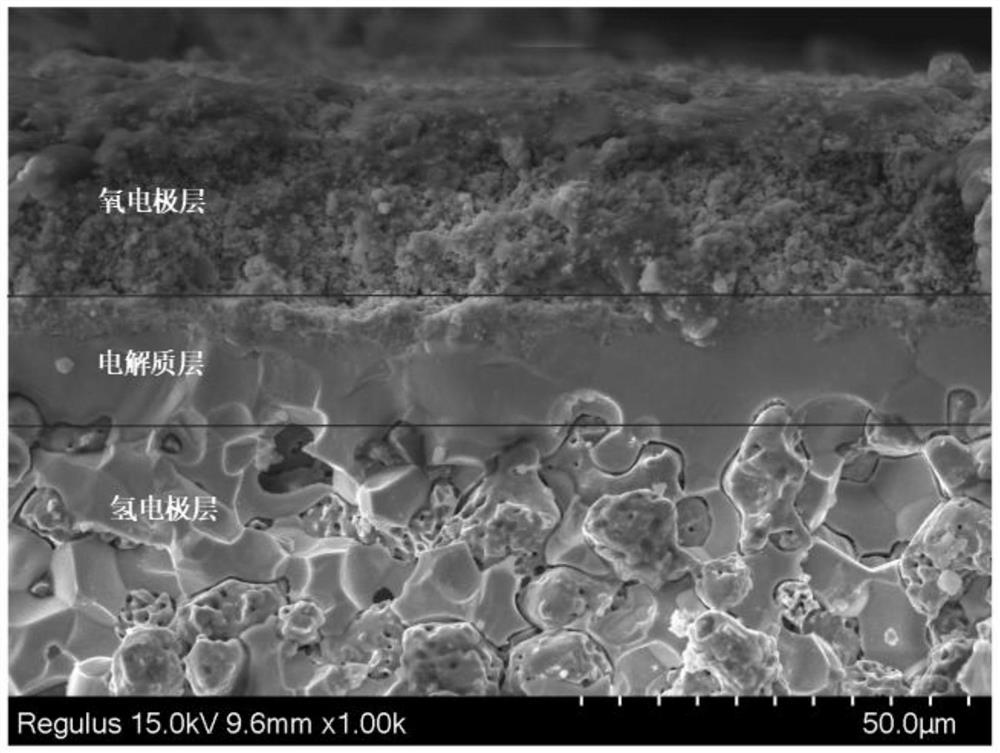

[0049] Weigh 0.2 and 36 grams of NiO powder and 10 and 24 grams of BZCYYb powder for the electrolyte and hydrogen electrode slurry, respectively. The hydrogen electrode slurry needs to add 6 grams of starch as a pore-forming agent, and add 15 and 15 grams of the electrolyte and hydrogen electrode slurry respectively. 33ml deionized water, 2% and 2.5% polyacrylic acid and a small amount of ammonia water as dispersant, add 3.9% and 9% polyvinyl alcohol binder, 3.23% and 13.8% polyethylene glycol-200, 3.23% and 13.8% glycerin Plasticizer, 0.8% and 1.5% 1-octanol antifoam, 4.2% and 1.16% 2,4,7,9-tetramethyl-5-decyne-4,7-diol surfactant, put In a planetary ball mill, ball mill at 400 rpm for 3.5 hours to mix evenly; after vacuum degassing treatment, adjust the knife height on the casting machine, and cast layer by layer to make a composite film blank; dry at room temperature for 24 hours , cut it into square pieces with an area of 80×80mm, and after removing the composite film bl...

Embodiment 2

[0054] In the middle of the electrolyte and hydrogen electrode layers in Example 1, an active layer is added, and the mass ratio of NiO to BZCYYb is 5:5, that is, three-layer composite casting. After co-firing, a half-cell with a structure of hydrogen electrode support layer / hydrogen electrode active layer / electrolyte layer is obtained, and other steps are consistent with Example 1.

[0055] The invention relates to a method for preparing a hydrogen electrode-supported proton conductor electrolyte composite membrane. Since the hydrogen electrode support is used, the electrolyte formed by water-based casting has a large area and a small thickness, and there is no pollution to the environment during the preparation process. After sintering The density of the electrolyte is higher, and its electrochemical performance and stability are improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com