Anti-corrosion polycarbonate sheet and preparation method thereof

A technology of polycarbonate board and polycarbonate, which is applied in the direction of anti-corrosion coatings and coatings, and can solve the problems of non-corrosion resistance and easy aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

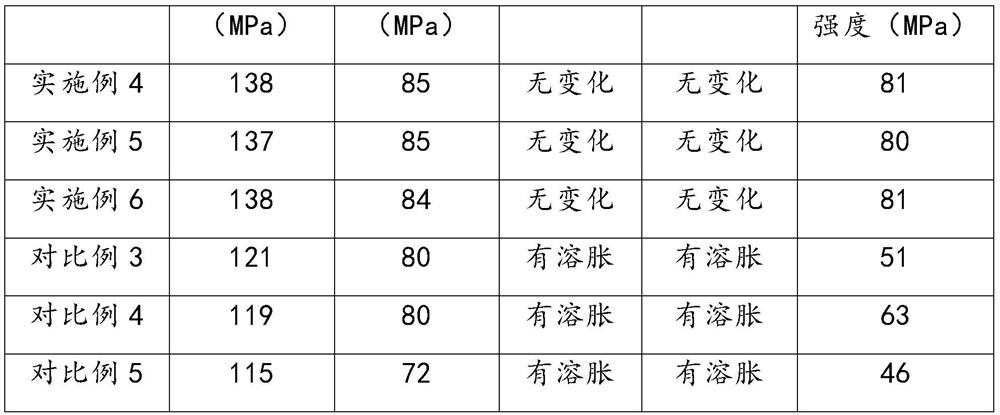

Examples

Embodiment 1

[0033] The present embodiment provides a kind of anticorrosion coating, and preparation steps are as follows:

[0034] Step 1: Stir and mix the emulsifier, monomer and 2 / 3 of the total mass of deionized water at 25°C for 30 minutes to obtain a pre-emulsion;

[0035] The second step is to mix the remaining deionized water and sodium bicarbonate, add 1 / 3 of the pre-emulsion, heat up to 70°C, add 1 / 2 of the total mass of the initiator solution, stir and mix at a speed of 100r / min for 1h, and obtain seed emulsion;

[0036] The third step is to add the remaining pre-emulsion and initiator solution to the seed emulsion, and keep it warm at 70°C for 4 hours. After the reaction, adjust the pH value to 8 with 25% ammonia water by mass fraction, and then cool to room temperature to obtain an anti-corrosion coating. .

[0037] The emulsifier is a mixture of alkylphenol polyoxyethylene ether and sodium lauryl sulfate at a mass ratio of 1:1, and the monomers are methyl methacrylate, modi...

Embodiment 2

[0045] The present embodiment provides a kind of anticorrosion coating, and preparation steps are as follows:

[0046] Step 1: Stir and mix the emulsifier, monomer and 2 / 3 of the total mass of deionized water at 25°C for 30 minutes to obtain a pre-emulsion;

[0047] The second step is to mix the remaining deionized water and sodium bicarbonate, add 1 / 3 of the pre-emulsion, heat up to 70°C, add 1 / 2 of the total mass of the initiator solution, and stir and mix at a speed of 150r / min for 1h to obtain seed emulsion;

[0048] The third step is to add the remaining pre-emulsion and initiator solution to the seed emulsion, and keep it warm for 5 hours at 70°C. After the reaction, adjust the pH value to 8 with ammonia water with a mass fraction of 25%, and then cool to room temperature to obtain an anti-corrosion coating. .

[0049] The emulsifier is a mixture of alkylphenol polyoxyethylene ether and sodium lauryl sulfate at a mass ratio of 1:1, and the monomers are methyl methacryl...

Embodiment 3

[0057] The present embodiment provides a kind of anticorrosion coating, and preparation steps are as follows:

[0058] Step 1: Stir and mix the emulsifier, monomer and 2 / 3 of the total mass of deionized water at 25°C for 30 minutes to obtain a pre-emulsion;

[0059] In the second step, mix the remaining deionized water and sodium bicarbonate, add 1 / 3 of the pre-emulsion, heat up to 70°C, add 1 / 2 of the total mass of the initiator solution, stir and mix at a speed of 200r / min for 1h, and obtain seed emulsion;

[0060] The third step is to add the remaining pre-emulsion and initiator solution to the seed emulsion, and keep it warm for 6 hours at 70°C. After the reaction, adjust the pH value to 8 with ammonia water with a mass fraction of 25%, and then cool to room temperature to obtain an anti-corrosion coating. .

[0061] The emulsifier is a mixture of alkylphenol polyoxyethylene ether and sodium lauryl sulfate at a mass ratio of 1:1, and the monomers are methyl methacrylate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com