Preparation method of water-resistant sulfur-resistant ultralow-temperature denitration catalyst and denitration catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

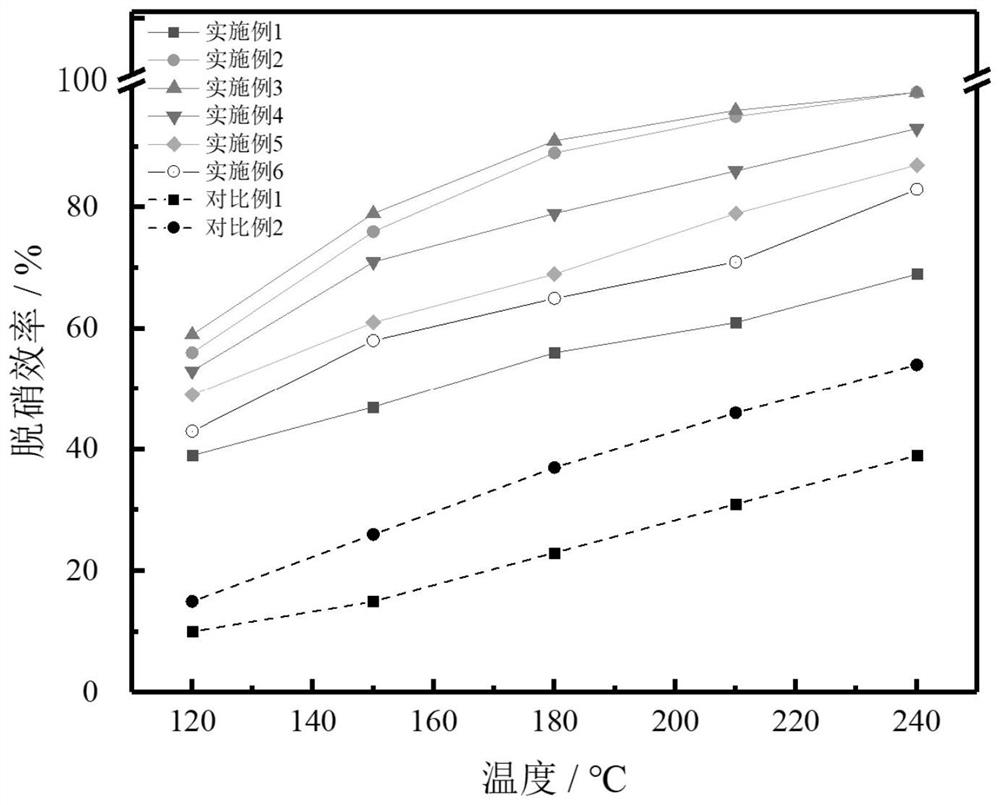

Embodiment 1

[0036] A method for preparing a water-resistant and sulfur-resistant ultra-low temperature denitrification catalyst, comprising the following steps:

[0037] (1) Weigh 0.656g of ammonium metavanadate, 0.59g of ammonium metatungstate, 0.58g of ammonium heptamolybdate, and 2.52g of manganese nitrate solution (50%), dissolve them in water respectively, then add 47g of titanium dioxide, and place in a water bath at 50°C Stirring under ambient conditions, drying and calcining to obtain an ultra-low temperature denitration catalyst; where V 2 o 5 、WO 3 , MoO3, MnO x , The mass ratio of titanium dioxide is 1:1:1:1:96;

[0038] (2) Weigh 20g of the ultra-low temperature denitration catalyst prepared in step (1) and dissolve it in 200ml of toluene, stir and disperse for 30min; then add 2g of perfluorooctyltriethoxysilane dropwise, stir under reflux for 8 hours, and condense The temperature is 80°C; after the reaction is completed, it is filtered and washed three times with toluene,...

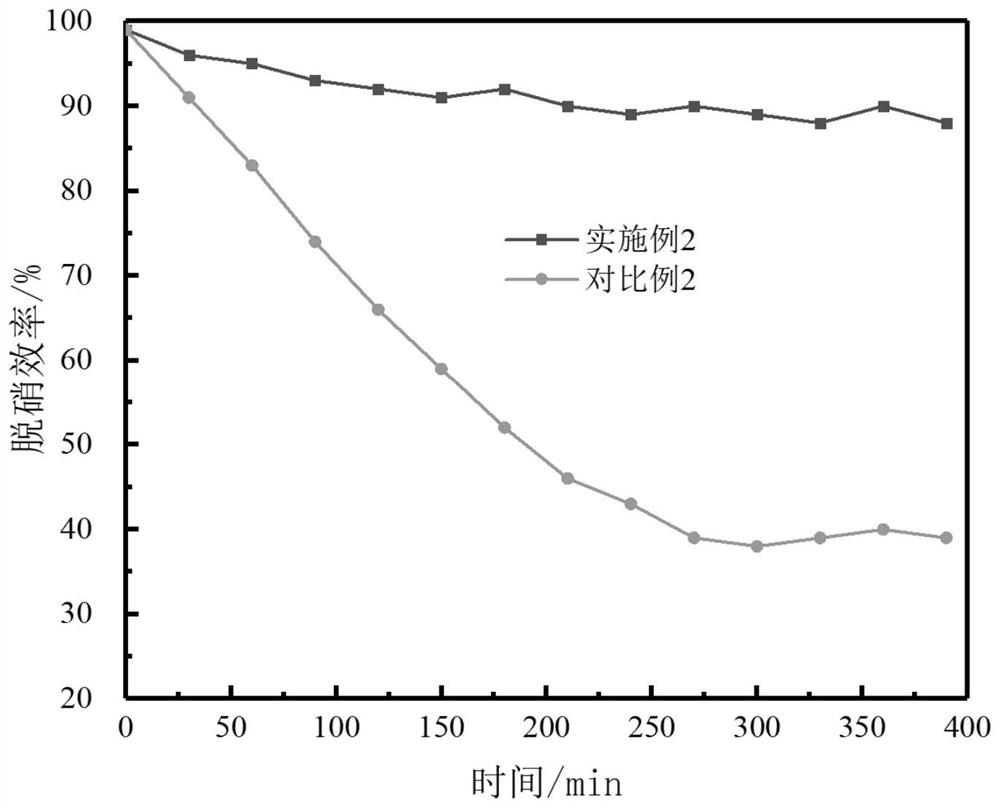

Embodiment 2

[0040] A method for preparing a water-resistant and sulfur-resistant ultra-low temperature denitrification catalyst, comprising the following steps:

[0041] (1) Weigh 1.97g of ammonium metavanadate, 1.76g of ammonium metatungstate, 1.73g of ammonium heptamolybdate, and 7.57g of manganese nitrate solution (50%), dissolve them in water respectively, then add 44g of titanium dioxide, and place in a water bath at 50°C Stirring under ambient conditions, drying and calcining to obtain an ultra-low temperature denitration catalyst; where V 2 o 5 、WO 3 、MoO 3 , MnO x , The mass ratio of titanium dioxide is 3:3:3:3:88;

[0042] (2) Weigh 20g of the ultra-low temperature denitration catalyst prepared in step (1) and dissolve it in 200ml of toluene, stir and disperse for 30min; then add 8g of perfluorooctyltriethoxysilane dropwise, stir under reflux for 8 hours, and condense The temperature is 80°C; after the reaction is completed, it is filtered and washed three times with toluene...

Embodiment 3

[0044] A method for preparing a water-resistant and sulfur-resistant ultra-low temperature denitrification catalyst, comprising the following steps:

[0045] (1) Weigh 3.28g of ammonium metavanadate, 2.94g of ammonium metatungstate, 2.88g of ammonium heptamolybdate, and 12.61g of manganese nitrate solution (50%), dissolve them in water respectively, then add 40g of titanium dioxide, and place in a water bath at 50°C Stirring under ambient conditions, drying and calcining to obtain an ultra-low temperature denitration catalyst; where V 2 o 5 、WO 3 、MoO 3 , MnO x , The mass ratio of titanium dioxide is 5:5:5:5:80;

[0046] (2) Weigh 20g of the ultra-low temperature denitration catalyst prepared in step (1) and dissolve it in 200ml of toluene, stir and disperse for 30min; then add 8g of perfluorooctyltriethoxysilane dropwise, stir under reflux for 8 hours, and condense The temperature is 80°C; after the reaction is completed, it is filtered and washed three times with toluen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com