Preparation method of propping agent coated with superhydrophobic polymeric membrane

A technology of polymer membranes and proppants, which is applied in chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problem of no contribution of proppant anti-fragmentation ability, change of wettability of solid surface, intermolecular Small force and other problems, to achieve the effect of facilitating hydrophobic oil conduction, improving surface hydrophobicity, and improving hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

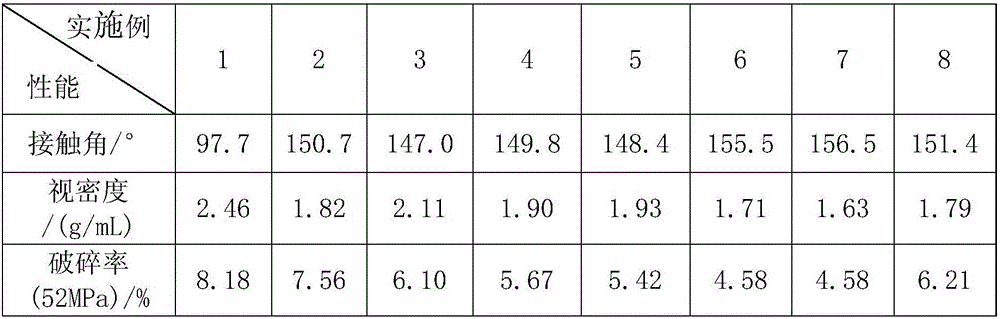

Embodiment 1

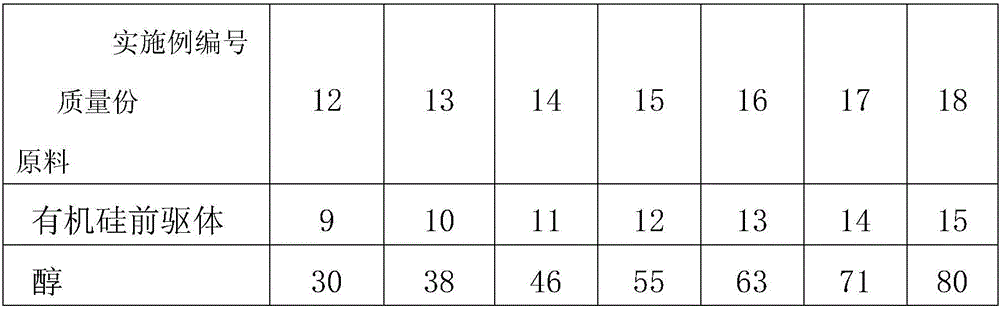

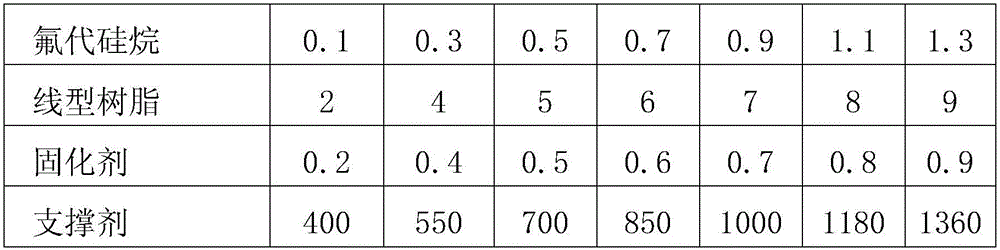

[0027] A preparation method of a proppant wrapped with a superhydrophobic polymer membrane, the steps are:

[0028] a. Mix 8 parts by mass of tetraethyl orthosilicate and 30 parts by mass of ethanol to obtain solution A, add quantitative ammonia water to the solution, adjust the pH value of the solution to about 12.1, and react at a temperature of 50 ° C for 2 hours, form nanoparticles. Afterwards, 0.1 parts by mass of perfluorodecylmethylsiloxane was added to solution A, and the reaction was continued for 2 hours to obtain solution B;

[0029] b. Mix solution B and 1.5 parts by mass of thermoplastic phenolic resin, heat up to 70°C, and stir for about 10 minutes to obtain a homogeneous mixture C;

[0030] c. Add 0.15 parts by mass of hexamethylenetetramine to mixture C. After mixing for about 10 minutes, mix with 300 parts by mass of proppant ceramsite and stir for 5 minutes. ~40 mesh) surface coated with a layer of super-hydrophobic polymer film, cured at 90°C for 3 hours, ...

Embodiment 2

[0032] A preparation method of a proppant wrapped with a superhydrophobic polymer membrane, the steps are:

[0033] a. Mix 8 parts by mass of tetraethyl orthosilicate and 40 parts by mass of ethanol to obtain solution A, add quantitative ammonia water to the solution, adjust the pH value of the solution to about 12.5, and react at 55°C for 2 hours , forming nanoparticles. After that, 1.3 parts by mass of perfluorodecyltriethoxysilane was added to solution A, and the reaction was continued for 0.5 hours to obtain solution B;

[0034] b. Mix solution B and 1.5 parts by mass of thermoplastic phenolic resin, heat up to 70°C, and stir for about 10 minutes to obtain a homogeneous mixture C;

[0035] c. Add 0.6 parts by mass of hexamethylenetetramine to the mixture C. After mixing for about 10 minutes, mix with 300 parts by mass of proppant ceramsite and stir for 5 minutes, wrap a piece of ceramsite (20 / 40 mesh) A layer of super-hydrophobic polymer film, placed at 120 ° C for 1 hou...

Embodiment 3

[0037] A preparation method of a proppant wrapped with a superhydrophobic polymer membrane, the steps are:

[0038] a. Mix 10 parts by mass of tetramethyl orthosilicate and 50 parts by mass of ethanol to obtain solution A, add quantitative ethylenediamine to the solution, adjust the pH value of the solution to about 12.3, and react at 60°C for 2 Hours, nanoparticles are formed. Afterwards, 0.1 parts by mass of perfluorodecyltriethoxysilane was added to solution A, and the reaction was continued for 1 hour to obtain solution B;

[0039] b. Mix solution B with 8 parts by mass of thermoplastic epoxy resin, heat up to 90°C, and stir for about 10 minutes to obtain a homogeneous mixture C;

[0040] c. Add 0.8 parts by mass of diethylenetriamine to mixture C, mix for about 10 minutes, mix with 600 parts by mass of proppant ceramsite and stir for 7 minutes, and wrap a layer on the surface of ceramsite (20 / 40 mesh) The super-hydrophobic polymer film is cured at 110°C for 2 hours, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com