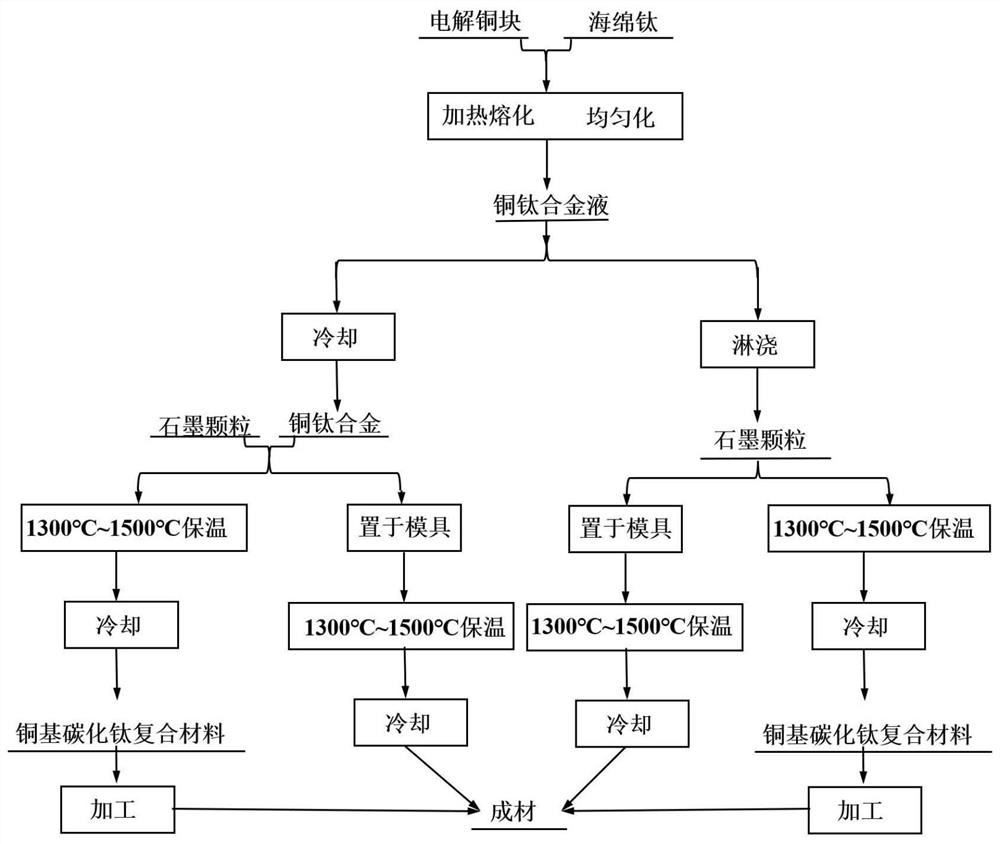

A method for preparing copper-based titanium carbide composite materials by in-situ reaction

A copper-based titanium carbide, in-situ reaction technology, applied in the field of metal composite material preparation, can solve the problems of high cost, easy introduction of impurities, unstable performance, etc., and achieve the effects of reducing production cost, simplifying preparation process, and excellent physical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037](1) Weigh the electrolytic copper block and titanium sponge according to the mass ratio of 9:1, place them in a corundum crucible, transfer them to an electromagnetic induction furnace protected by 100mL / min argon, heat at 1300°C until the raw materials are in a molten state, and then keep warm After 30 minutes, the alloy liquid completed the alloying process, then the power of the electromagnetic induction furnace was turned off, and after natural cooling, the copper-titanium alloy ingot was taken out, and wire-cut into small pieces of copper-titanium alloy.

[0038] (2) Take copper-titanium alloy pieces and 200-mesh graphite particles (the molar ratio of titanium element in copper-titanium alloy to carbon element in graphite is 1), and evenly spread the weighed graphite particles on the bottom of corundum porcelain boat (laying The thickness is about 3mm), and then the copper-titanium alloy small pieces are evenly placed on the top of the graphite particles.

[0039] (...

Embodiment 2

[0044] (1) Weigh the electrolytic copper block and titanium sponge according to the mass ratio of 9:1, place them in a corundum crucible, transfer them to an electromagnetic induction furnace protected by 100mL / min argon, heat at 1300°C until the raw materials are in a molten state, and then keep warm After 30 minutes, the alloy liquid completed the alloying process, then the power of the electromagnetic induction furnace was turned off, and after natural cooling, the copper-titanium alloy ingot was taken out, and wire-cut into small pieces of copper-titanium alloy.

[0045] (2) Weigh copper-titanium alloy pieces and 200-mesh graphite particles (the molar ratio of titanium in copper-titanium alloy to carbon in graphite is 1.6), and evenly spread the weighed graphite particles in the mold of the required shape , and then evenly place the small pieces of copper-titanium alloy on the top of the graphite particles.

[0046] (3) The mold with copper-titanium alloy nubs and graphite...

Embodiment 3

[0049] (1) Weigh the electrolytic copper block and titanium sponge according to the mass ratio of 9:1, place them in a corundum crucible, transfer them to an electromagnetic induction furnace protected by 100mL / min argon, heat at 1300°C until the raw materials are in a molten state, and then keep warm After 30 minutes, the alloy liquid completes the alloying process, and then the power supply of the electromagnetic induction furnace is turned off to obtain the copper-titanium alloy liquid.

[0050] (2) The copper-titanium alloy liquid is poured onto 200-mesh graphite particles (the molar ratio of the titanium element in the copper-titanium alloy to the carbon element in the graphite is 1) to obtain an alloy mixture, and the alloy mixture is placed in a mold of a desired shape.

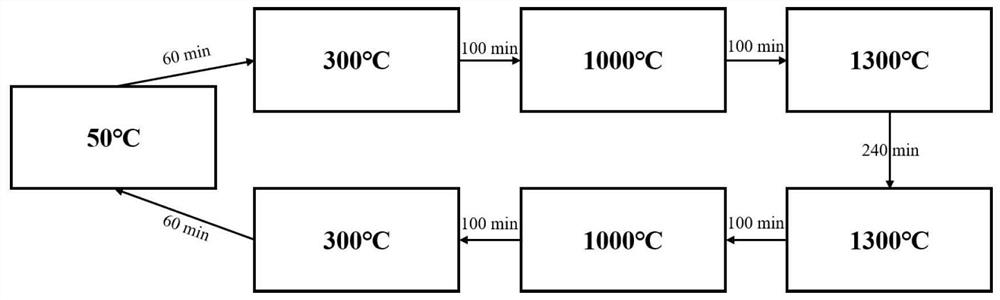

[0051] (3) The mold containing the alloy mixture was placed in a horizontal furnace at 1300°C with an argon flow rate of 100mL / min, then kept for 240min, and then figure 2 The temperature program was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com