Molybdenum rod for vacuum electronic device and preparation method thereof

A technology for vacuum electronic devices and molybdenum rods, applied in vacuum tubes, electrical components, circuits, etc., can solve the problem of being limited to a diameter of less than 20mm; Jinduicheng Molybdenum Industry Co., Ltd. applies, but cannot meet the performance of large-diameter, high-strength and tough molybdenum rods It does not involve issues such as bar density and toughness, and achieves the effect of uniform and fine microstructure, good strength and toughness, and good machinability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

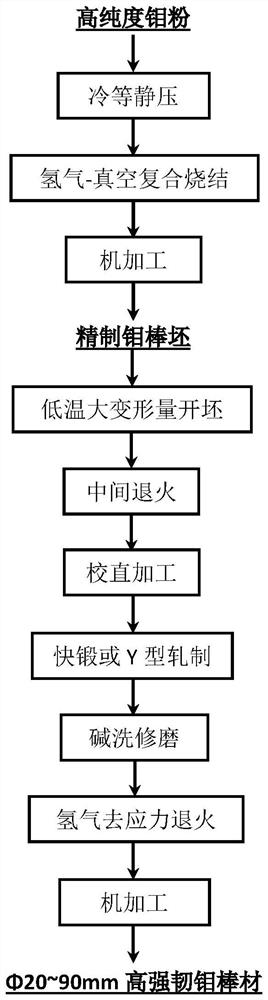

[0034] The technological process of molybdenum rod preparation method of the present invention is as figure 1As shown, the following steps are included: 1 cold isostatic compact preparation; 2 hydrogen-vacuum composite sintering; 3 low temperature large deformation billet opening; 4 intermediate annealing and straightening processing; 5 diameter reduction processing; 6 alkali cleaning and grinding; 7. Annealing treatment; 8. Machining; Finally, a large-diameter, high-strength and tough molybdenum rod with uniform structure composition, high density, good strength and toughness is obtained.

[0035] A method for preparing large-diameter, high-strength and tough molybdenum rods, comprising the following steps:

[0036] (1) Preparation of cold isostatic compact: use high-purity molybdenum powder with medium particle size (Fischer particle size 3-5 μm) as raw material, and use cold isostatic pressing to obtain a refined molybdenum rod compact with regular shape and uniform size, w...

Embodiment 1

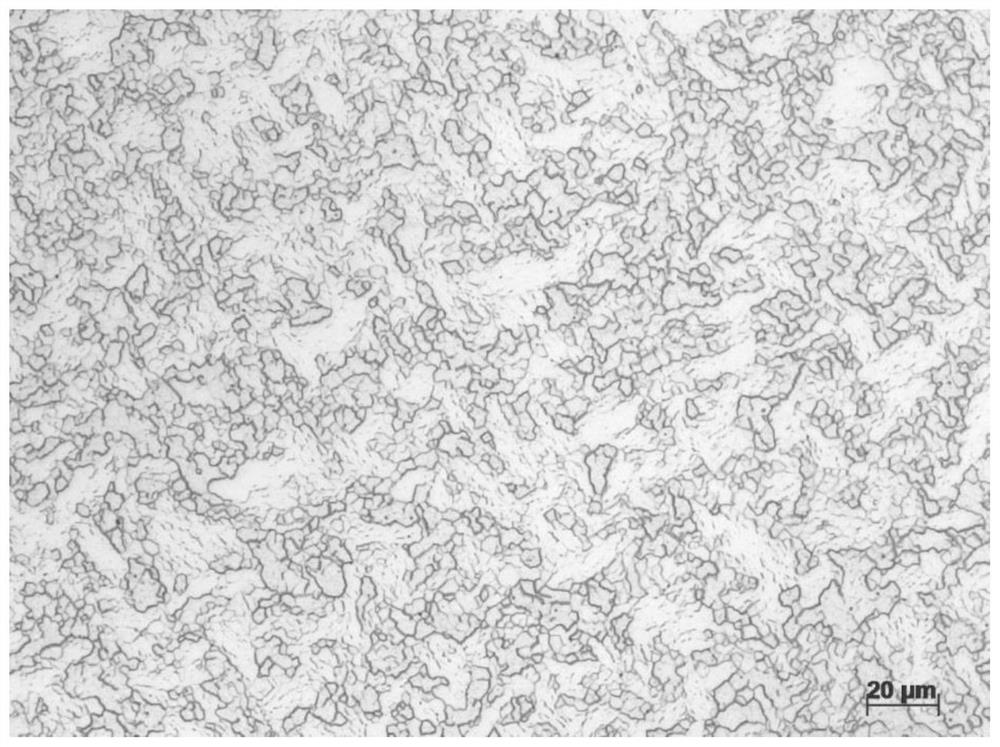

[0045] Using the molybdenum powder with a Fibonacci particle size of 5.0 μm as a raw material, the Mo content is 99.99% by weight, the impurity C / O is 50ppm / 500ppm, and the K / W is 20ppm / 50ppm respectively; the high-purity molybdenum powder is evenly packed into In the soft rubber sleeve fixed by the PVC rigid sleeve, the material must be knocked evenly with a pestle and tightly sealed with iron wires when loading, and cold isostatic pressing under a pressure of 200MPa for 10 minutes to obtain a refined molybdenum billet with regular shape and uniform size; The molybdenum rod-shaped compact was placed in a hydrogen-vacuum dual-purpose high-temperature furnace, and sintered at 1100°C for 1h in a high-purity hydrogen atmosphere with a dew point of -40°C; after that, the atmosphere was directly changed to 10 -2 Pa vacuum, complete high temperature vacuum sintering at 1700°C for 1 hour, and obtain a density of 9.9g / cm 3 And uniform, qualified grain size, low impurity refined sinter...

Embodiment 2

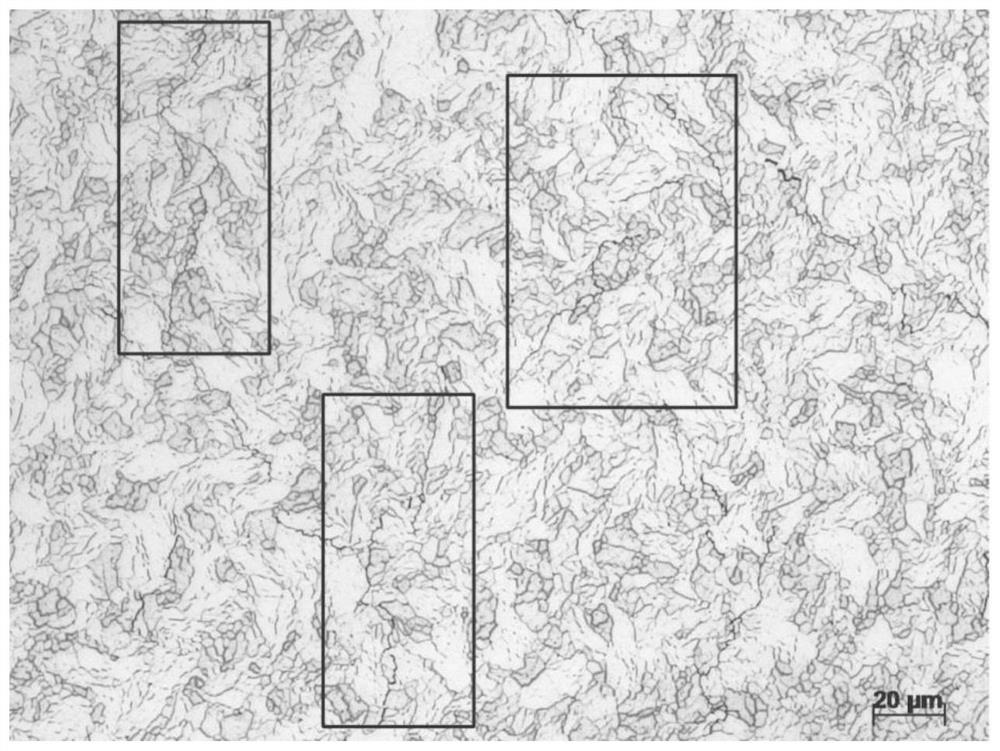

[0047] The molybdenum powder with a Fibonacci particle size of 4.0 μm is used as a raw material, and its Mo content is 99.99% by weight, the impurity C / O is 50ppm / 500ppm, and the K / W is 20ppm / 50ppm respectively; the high-purity molybdenum powder is evenly packed into The carbon steel rigid sleeve is fixed in the soft rubber sleeve, and the material must be pounded evenly when loading, and it must be tightly sealed with iron wires. Cold isostatic pressing under 250MPa pressure for 10 minutes to obtain a refined molybdenum billet with regular shape and uniform size. ; Place the molybdenum rod-shaped compact in a hydrogen-vacuum dual-purpose high-temperature furnace, and sinter at 1200°C for 2 hours in a high-purity hydrogen atmosphere with a dew point of -60°C; then directly switch the atmosphere to 10 in the same furnace -3 Pa vacuum, complete high temperature vacuum sintering at 1800°C for 2 hours, and obtain a density of 9.7g / cm 3 And uniform, qualified grain size, low impuri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com