Device for improving tightness of steam turbine vacuum system

A vacuum system and tightness technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of condenser vacuum deterioration, affecting unit vacuum, inconvenient monitoring of water level, etc., to improve reliability and economy. performance and reduce maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 下面结合附图对本发明做清楚完整的描述,以使本领域的技术人员在不需要作出创造性劳动的条件下,能够充分实施本发明。

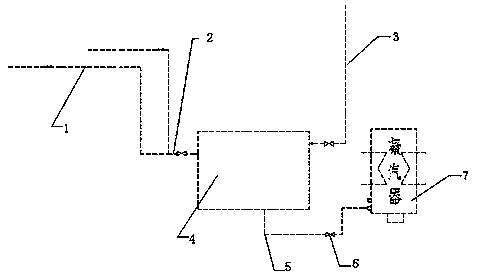

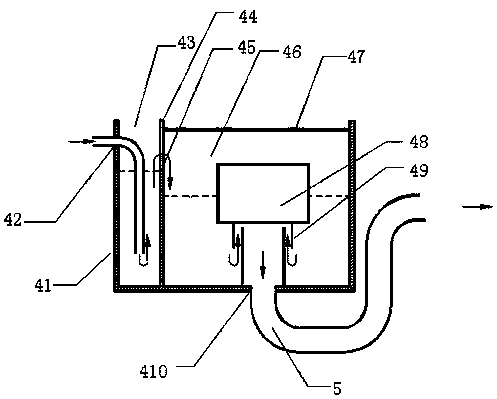

[0020] 本发明的具体实施方式是:如 Figure 2-3 所示,一种提高汽轮机真空系统严密性的装置,包括多个汽泵密封水回水管1、回水母管2、轴加汽侧回水管3、水封装置4、出水管5、截止阀6和凝汽器7,所述水封装置4包括箱体41、液位浮子48、箱盖,所述箱体41两侧分别设有进水口42和出水口410,所述箱体41通过隔板44设置成两部分,一部分为进水槽43,另一部分为出水槽46,隔板44设有溢流口,液位浮子48设置箱体41的出水槽46内,所述汽泵密封水回水管1均连通至回水母管2,所述回水母管2和轴加汽侧回水管3从箱体41的进水口42进入至进水槽43内,所述出水管5一端从箱体41的出水口410进入出水槽46内,另一端和凝汽器7连接,所述截止阀6设置在出水管5上,用于控制回水量。

[0021] 进一步地,所述汽泵密封水回水管1为两个。

[0022] 进一步地,所述箱盖上设有推拉式观察窗,便于检查。

[0023] 进一步地,所述回水母管2和轴加汽侧回水管3在进水槽43内的位置低于溢流口45高度,进水口42位置高于溢流口45位置。

[0024] 进一步地,所述液位浮子48底部设有两个导向套49,所述导向套49上均匀设有多个通孔。

[0025] 进一步地,所述出水槽46上部设有限位板47,其高度高于液位浮子48,防止水位过高将液位浮子48顶出箱体41。

[0026] 进一步地,所述出水管5在出水槽46内的高度高于导向套49底部位置。

[0027] 如一优选的实施方式中,箱体41高度为高度1000mm,液位浮子48用4mm的不锈钢板制作,直径800mm,高度400mm,最大浸没深度200mm,在液位浮子48下方使用不锈钢无缝钢管制作导向套49,导向套49直径245mm,高度290mm,导向套49周向均布通孔,使用不锈钢无缝钢管制作箱体41底部的出水管5,出水管5高度300mm,使用槽钢制作液位浮子48的限位板47,防止水位过高将液位浮子48顶出箱体41,限位板47距箱体41底部880mm。

[0028] 以上对本发明的较佳实施例进行了描述,需要指出的是,本发明并不局限于上述特定实施方式...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com