Sorting machine visual inspection device

A visual inspection device and sorting machine technology, applied in sorting and other directions, can solve problems such as machine downtime, increased workload of equipment maintenance personnel, and decline, achieving low cost, high vacuum airtightness, and low wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the spirit of the present invention, it will be further described below in conjunction with some preferred embodiments of the present invention.

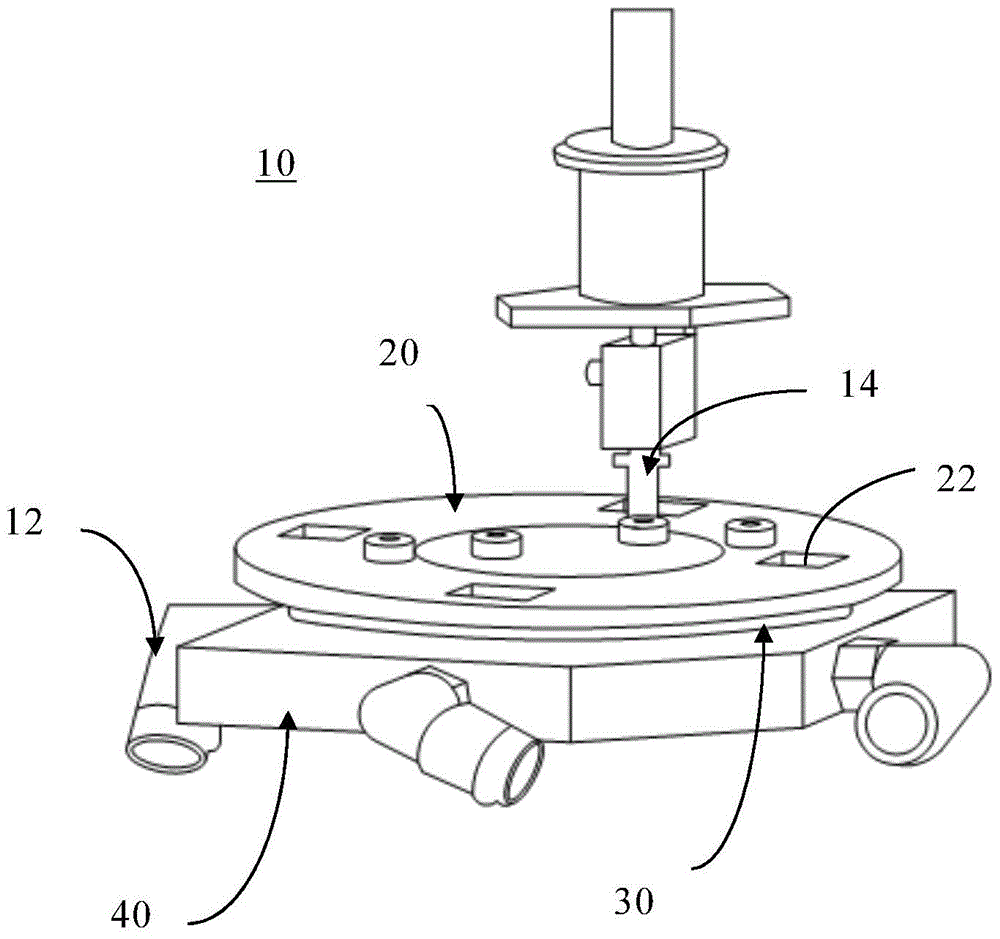

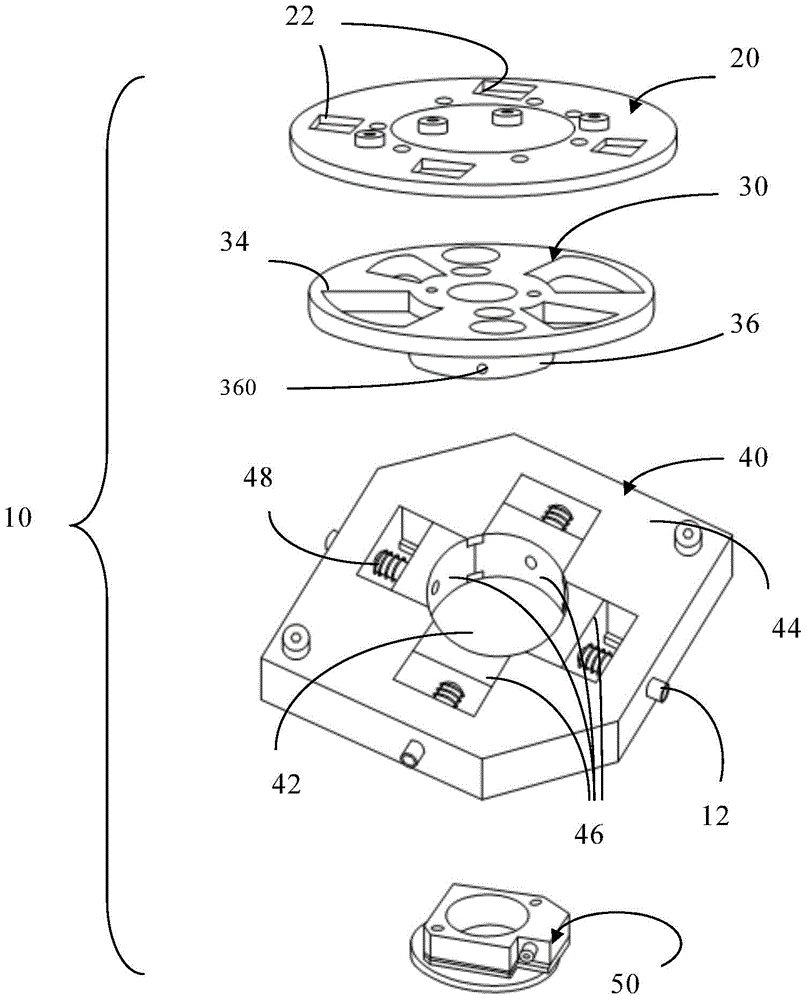

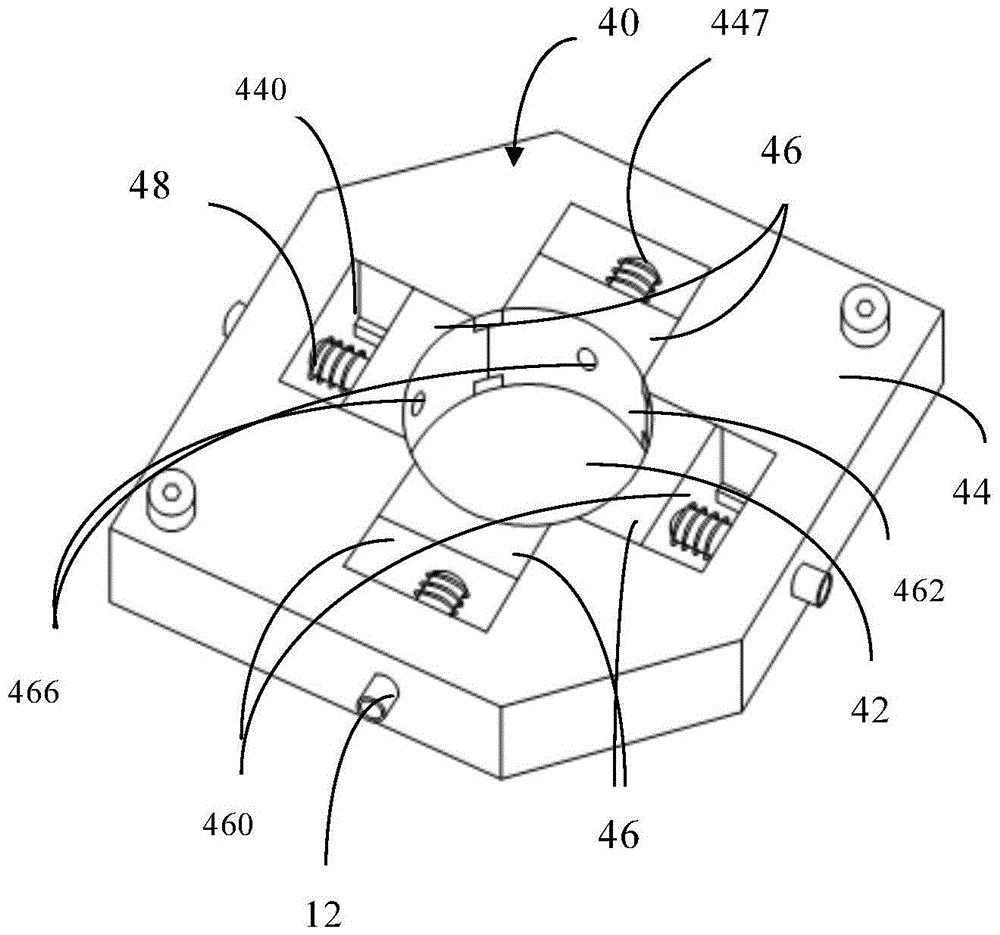

[0015] On a sorting machine for sorting electronic components, such as semiconductor packages, the visual inspection device usually includes a rotary table and a carrier table in a mother-in-law structure. The carrying platform is provided with a rotating space for the rotating shaft of the rotating platform to rotate at a high speed therein, and to maintain vacuum and airtight contact between the two. Since the bearing table is used to limit the rotation table in a way of stress compression, the rotation table and the bearing table need to be made of wear-resistant and hard materials, such as tungsten steel. However, this kind of material is usually expensive, highly brittle, and requires precise dimensions. Once deformed, it cannot be returned to its original size through mechanical processing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com