A helical tube type absorption heat exchanger for district heating

A spiral heat exchange tube and absorption technology, applied in the field of energy saving, can solve the problems of reducing the heat transfer capacity of the absorption heat exchange unit, the difficulty of internal structure processing, and the reduction of space utilization, so as to reduce the difficulty of processing and manpower cost, improve space utilization, and improve the effect of vacuum airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

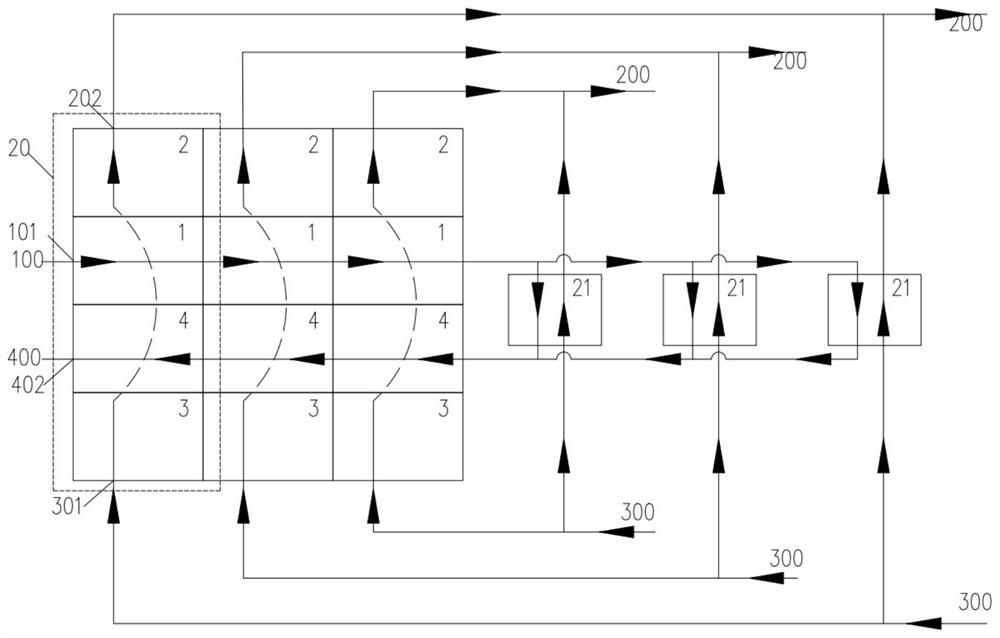

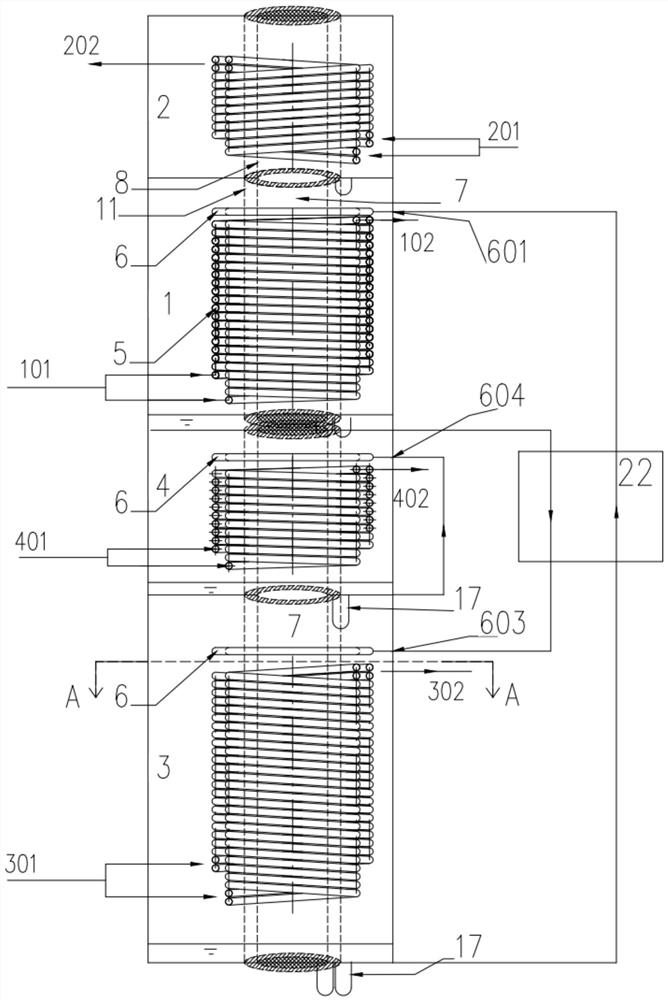

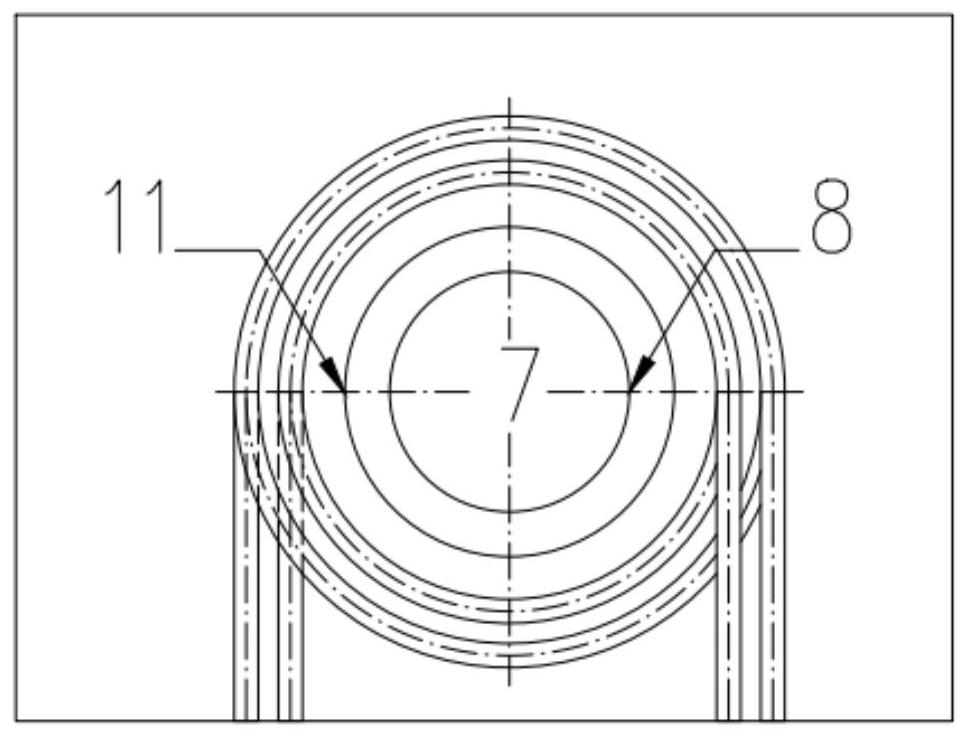

[0027] like Figure 1 to Figure 3 The illustrated embodiment 1 of the present invention includes: y independent 2≤y≤10 helical tube type absorption heat exchange units 20 and y water-water heat exchangers 21; The heat exchange unit 20 is divided into first, second, The generator 1, the condenser 2, the absorber 3, the evaporator 4 and the solution heat exchanger 22 arranged on the side of the heat exchange unit of the linear heat exchange tube, wherein the upper condenser 2 and the lower generator 1 are arranged in the The central cylindrical steam channel 7 is connected, and the upper evaporator 4 and the lower absorber 3 are also connected through the inner cylindrical steam channel 7; the cylindrical steam channel 7 is equipped with an auxiliary cylindrical orifice plate baffle plate 11. At least one turn of the spiral heat exchange tube group 5 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com