A Microcurrent Cesium Ion Source

A cesium ion and micro-current technology, applied in the field of ion sources, can solve problems such as harsh conditions of use, short service life, and difficulty in controlling the current of the ion source, and achieve the effects of high cesium utilization, long life, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

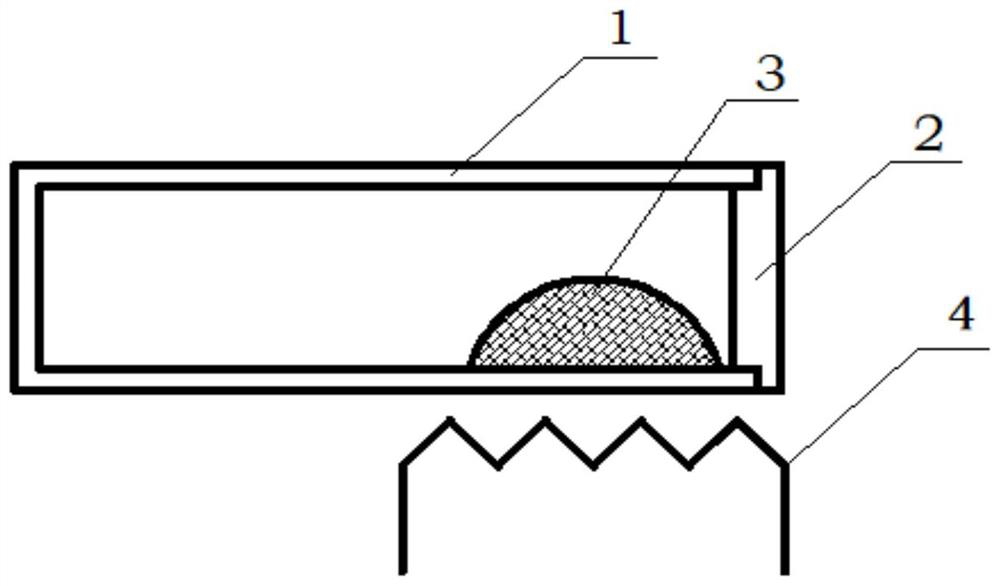

[0030] The present embodiment provides a kind of micro-current cesium ion source, such as figure 1 It includes a cesium storage body 1, a sealing cover 2, a cesium source 3 and a heater 4; the sealing cover 2 forms a vacuum-sealed container with the cesium storage body through vacuum sealing welding, and the cesium source 3 is installed in the vacuum chamber before welding. In the sealed container, the cesium source 3 can be elemental cesium or a cesium salt that is heated to generate elemental cesium. The heater 4 heats the vacuum-sealed container and the cesium source 3 to a high temperature state. The cesium salt generates elemental cesium at a high temperature, and the elemental cesium is passed through Heating and gasification forms cesium vapor, and gaseous cesium atoms diffuse through the top cover to the surface of the top cover and complete ionization on the surface to generate cesium ions.

[0031] In this embodiment, the sealing cover 2 is made of molybdenum materia...

Embodiment 2

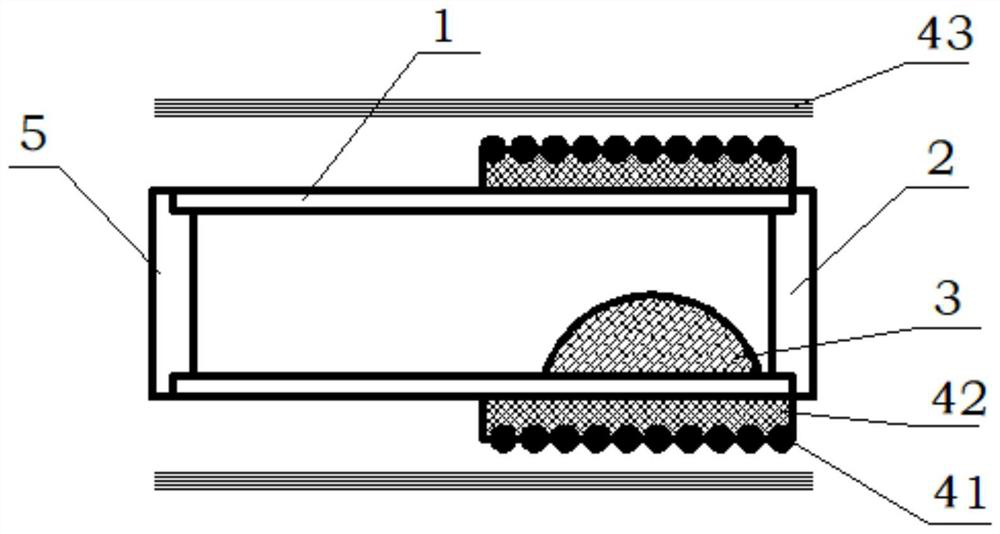

[0035] The present embodiment provides a kind of micro-current cesium ion source, such as figure 2 Shown includes a cesium storage body 1, a sealing cover 2, a cesium source 3, a heater 4 and a top cover 5. In this embodiment, the heater 4 is composed of a heating wire 41, an insulating ceramic 42 and a heat shield 43; the sealing cover 2 passes through Electron beam welding and the cesium storage body form a vacuum-sealed container, and the cesium source 3 is installed in the vacuum-sealed container before welding, and the heater 4 heats the vacuum-sealed container and the cesium source 3 to a high temperature state. The gaseous cesium atoms diffuse through the top cover to the surface of the top cover and complete ionization on the surface to generate cesium ions.

[0036] In this embodiment, the sealing cover 2 is made of molybdenum material through turning; the cesium storage body 1 and the top cover 5 are made of metal tantalum rod through turning;

[0037] In this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com