Secondary epitaxy method of N-type heavily-doped thin-layer gallium nitride material

A secondary epitaxy and heavy doping technology, applied in the secondary epitaxy field of gallium nitride materials, can solve the problems of aggravating the deterioration of GaN crystal quality, increase in resistivity, and high requirements for vacuum conditions, and improve material quality and surface morphology. , reduce ohmic contact resistance, improve the effect of parasitic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

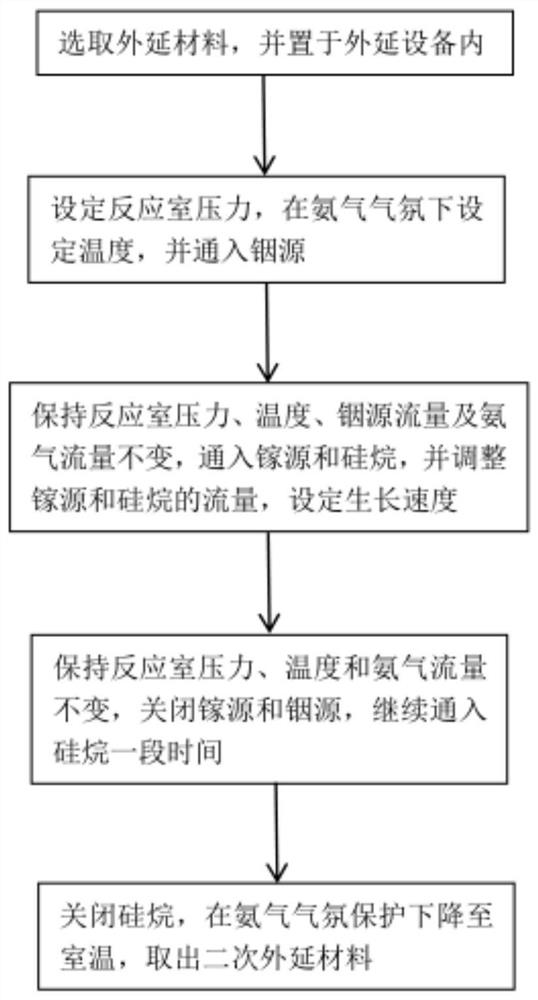

[0023] The secondary epitaxy method of thin-layer GaN material of the present invention, as figure 1 The flowchart shown includes the following steps:

[0024] (1) Select the surface of III-V nitrides such as GaN as the epitaxial material, or the surface of various semiconductor materials and devices as the epitaxial material, and place it in MOCVD (Metal-organic Chemical Vapor Deposition) and other epitaxial growth on the base of the device.

[0025] (2) Set the pressure of the reaction chamber as P, and the ammonia gas (NH 3 ) atmosphere to raise the temperature of the reaction chamber to T, and then feed the flow rate of 1×10 -5 ~1×10 -4 mol / min indium source, and last for 0.5-2min (minutes).

[0026] The growth temperature T ranges from 830 to 990°C. In order to suppress the N-type heavily doped GaN material during the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com