3D printing grade polyether-ether-ketone resin special material, preparation and application thereof, 3D printing interlayer reinforced polyether-ether-ketone alloy material and preparation thereof

A polyether ether ketone resin, 3D printing technology, applied in the field of 3D printing materials, can solve the problems of material decomposition and poor interlayer bonding, and achieve good compatibility, high temperature resistance and stability, and good processing stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention provides a preparation method for 3D printing grade polyether ether ketone resin special material described in the above technical solution, comprising the following steps:

[0036] Mix 4,4'-difluorobenzophenone, hydroquinone, alkali catalyst, melted diphenyl sulfone and water-carrying agent, carry out water-carrying and polymerization reactions in sequence, and add 4-fluorodiphenyl Phenyl sulfone is capped to obtain special materials for 3D printing grade polyetheretherketone resin.

[0037] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0038] In the present invention, the molar ratio of the 4,4'-difluorobenzophenone to hydroquinone is preferably (1.005-1.05):1, more preferably 1.02-1.05:1, even more preferably 1.03: 1.

[0039] In the present invention, the alkali catalyst preferably includes sodium carbonate and potassium ca...

Embodiment 1

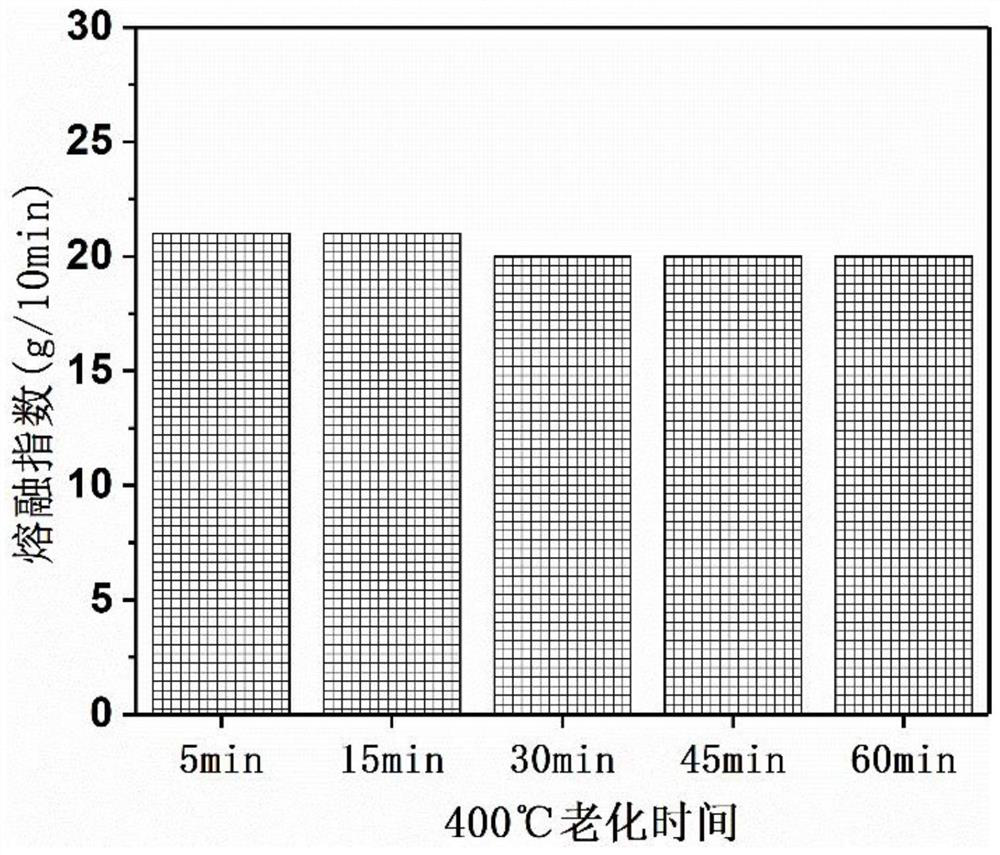

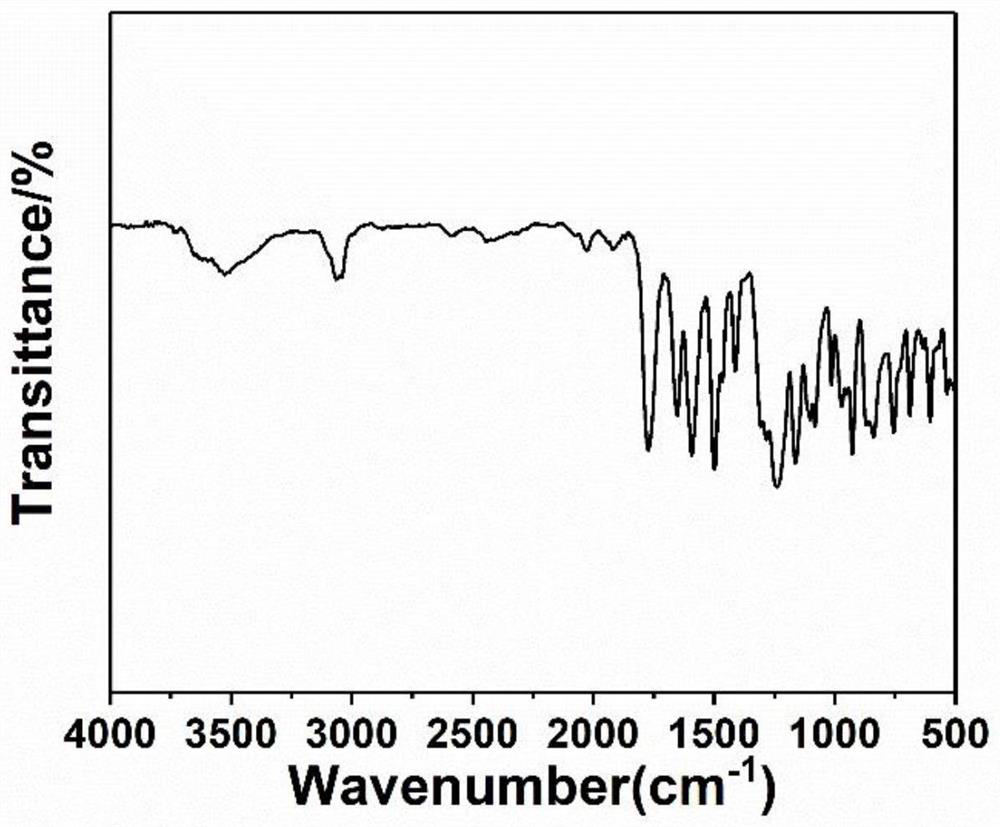

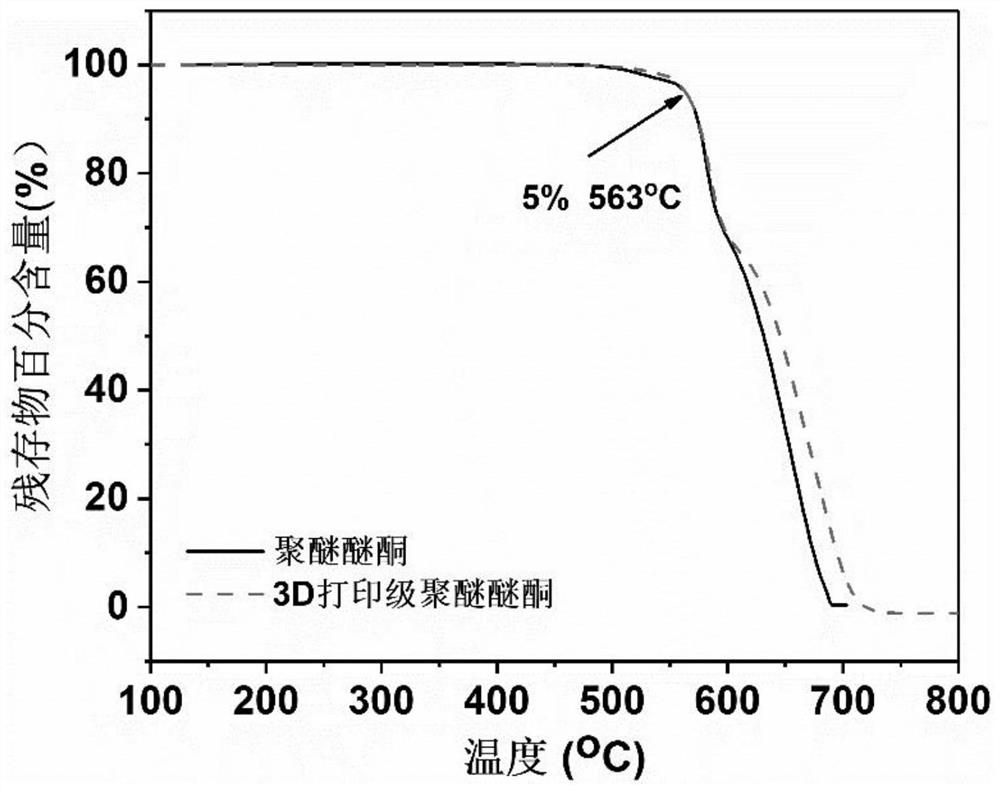

[0070] Add 997.992g of diphenyl sulfone into a three-neck flask equipped with an argon vent, heat to 140°C until the diphenyl sulfone melts into a liquid, then add 222.564g of 4,4'-difluorobenzophenone in sequence (1.02mol) and anhydrous sodium carbonate 127.2g (1.2mol), anhydrous potassium carbonate 1.38g (1.01mol), hydroquinone 110.1g (1mol), the solid content of the gained reaction system is 25wt%, finally add 300mL Xylene, then gradually heat up to 170°C with water for 2 hours, continue to heat up to 210°C for 1 hour, heat up to 250°C for 2 hours, and finally heat up to 310°C for 1 hour; add 4-fluorodiphenylsulfone monomer to the obtained product (2.36g) (0.01mol), after continuing to react for 1 hour, the material was discharged into deionized water, and the obtained strip product was pulverized by a high-speed pulverizer, and then washed 5 times with acetone and deionized water respectively to obtain 3D printing grade polyether Special material for ether ketone resin, th...

Embodiment 2

[0072] Add 1004.538g of diphenylsulfone into a three-neck flask equipped with an argon vent, heat to 140°C until the diphenylsulfone melts into a liquid, and then add 224.746g of 4,4'-difluorobenzophenone in sequence (1.03mol) and anhydrous sodium carbonate 127.2g (1.2mol), anhydrous potassium carbonate 1.38g (0.01mol), add hydroquinone 110.1g (1mol), the solid content of gained reaction system is 25wt%, finally add 300mL of xylene, then gradually raise the temperature to 170°C with water for 2h, continue to raise the temperature to 210°C for 1h, gradually raise the temperature to 250°C for 2h, and finally raise the temperature to 310°C for 1h; add 4-fluorodiphenylsulfone to the obtained product Monomer (2.36g) (0.01mol), after continuing to react for 1 hour, was discharged into deionized water, and the resulting strip-shaped product was pulverized by a high-speed pulverizer, and washed 5 times with acetone and deionized water respectively to obtain 3D printed Grade polyethere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com