Coral-like strip-shaped porous carbon as well as preparation method and application thereof

A technology of porous carbon and coral, applied in the field of its preparation, coral-like strip-shaped porous carbon, can solve the problems of difficult to realize large-scale preparation of electrode materials, increase the cost of electrode materials, and cannot be applied in a large scale, and achieve fast lithium storage reaction power The effect of improving energy density and service life, and stabilizing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] For this reason, the application firstly provides a preparation method of coral-like strip-shaped porous carbon, comprising the following steps:

[0043] Mix coal tar pitch and template activator, and calcine at high temperature to obtain coral-like strip-shaped porous carbon;

[0044] The template activator is potassium bicarbonate.

[0045] The preparation method of the porous carbon described in the present invention has universal applicability, and can carry out the preparation of the kilogram-scale porous carbon-based material at the same time, and the prepared carbon material has the hierarchical channel structure of micropore and mesopore composite, so the porous carbon material prepared by the present invention Compared with graphite in the negative electrode of lithium-ion batteries / capacitors, carbon materials have better lithium storage capacity, exhibit higher lithium storage specific capacity, and can greatly improve the energy density and cycle life of com...

Embodiment 1

[0065] This embodiment provides a preparation method of strip-shaped porous carbon (HPC-3), the preparation method of the porous carbon (HPC-3), comprising the following steps:

[0066] (1) Weigh 1.0 g of coal tar pitch and 3.0 g of potassium bicarbonate, grind them in a 250 mL agate mortar for 10 min, and mix well;

[0067] (2) Transfer the obtained mixture into a 20mL corundum boat, place it in a horizontal tube furnace filled with nitrogen and raise the temperature to 800°C at a heating rate of 5°C / min and keep it for 120min;

[0068] (3) When the temperature of the tube furnace is lowered to room temperature, transfer the product obtained after calcination to a 250mL beaker, add an appropriate amount of water to remove the remaining carbonate after calcination, and then transfer the product obtained by vacuum filtration to a 60°C oven After drying for 24 hours, the final product was obtained, named HPC-3.

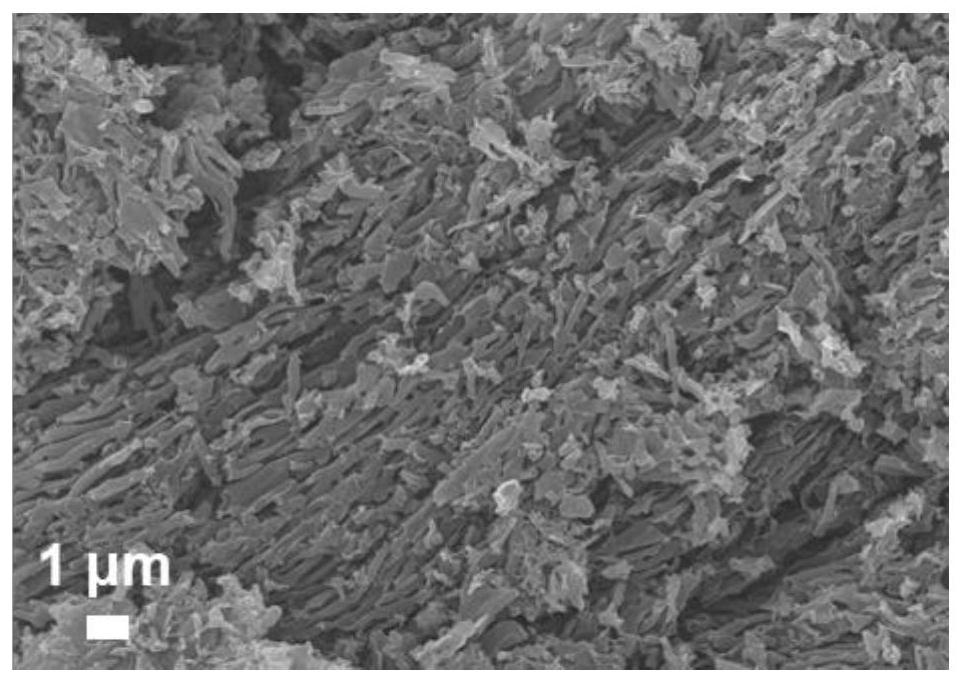

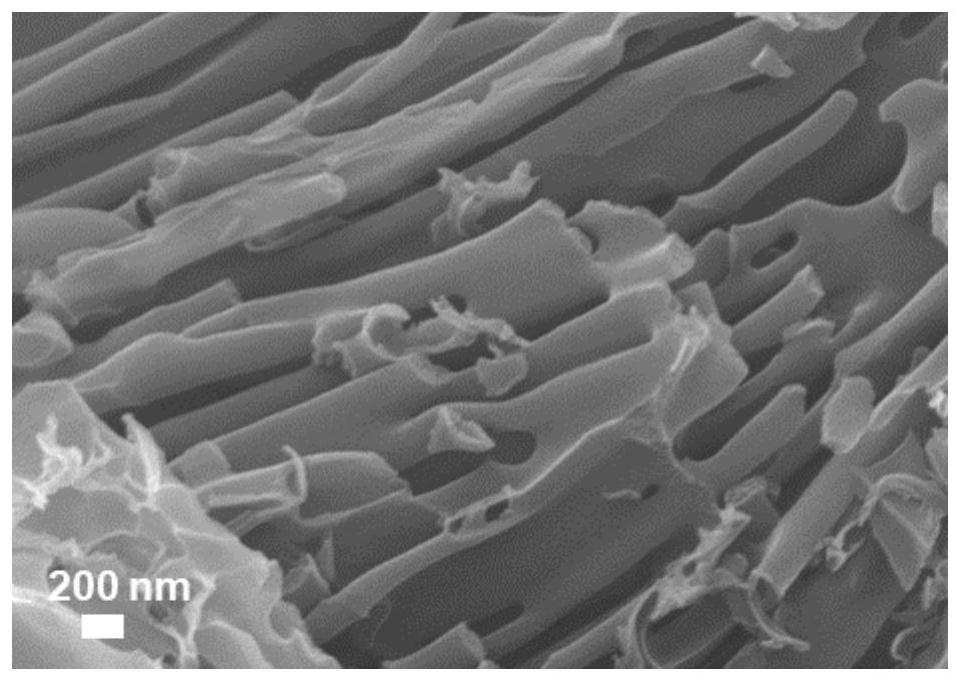

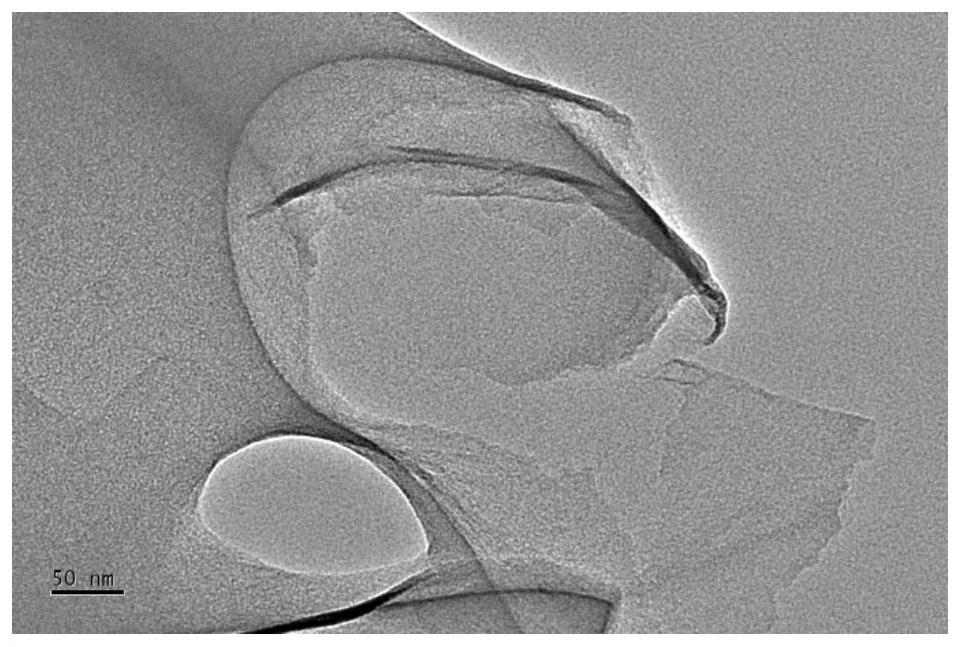

[0069] figure 1 and figure 2 The scanning electron microscope ...

Embodiment 2

[0074] This embodiment provides a preparation method of strip-shaped porous carbon (HPC-2), the preparation method of the porous carbon (HPC-2) comprises the following steps:

[0075] (1) Weigh 1.0 g of coal tar pitch and 2.0 g of potassium bicarbonate, grind them in a 250 mL agate mortar for 10 min, and mix well;

[0076] (2) Transfer the obtained mixture into a 20mL corundum boat, place it in a horizontal tube furnace filled with nitrogen and raise the temperature to 800°C at a heating rate of 5°C / min and keep it for 120min;

[0077] (3) When the temperature of the tube furnace is lowered to room temperature, transfer the product obtained after calcination to a 250mL beaker, add an appropriate amount of water to remove the remaining carbonate after calcination, and then transfer the product obtained by vacuum filtration to a 60°C oven After drying for 24 hours, the final product was obtained, named HPC-2.

[0078] Figure 6 and Figure 7 The scanning electron micrograph o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com