Solvent-free polylactic acid bio-based polyurethane synthetic leather, preparation method and application

A solvent-free polyurethane and polylactic acid technology, which is applied in textiles, papermaking, and fiber processing, can solve problems such as poor durability, low strength, and poor stability, and achieve high peel strength, good wear resistance, and high room temperature flexure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

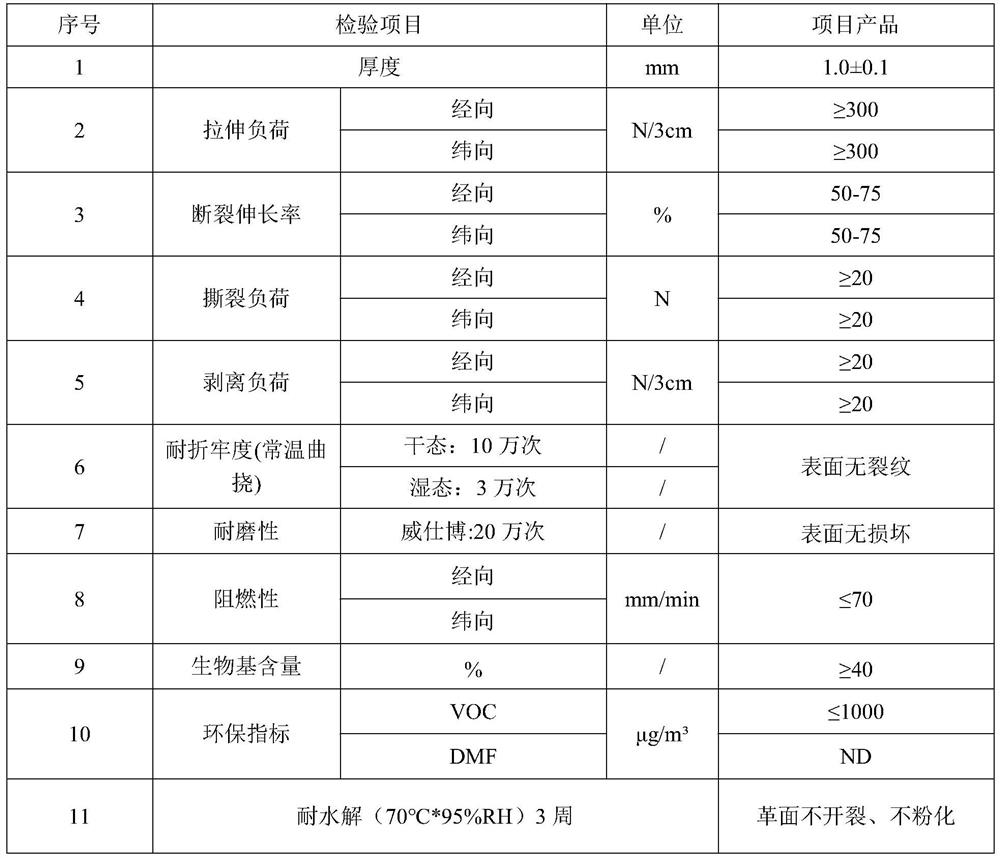

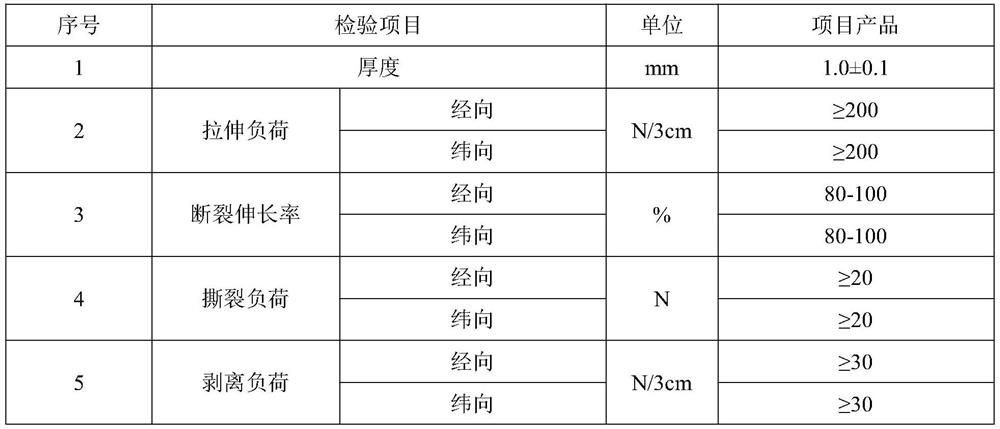

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing a solvent-free polylactic acid bio-based polyurethane synthetic leather. The synthetic leather preparation method includes the following steps: coating a water-based polyurethane surface layer slurry on a release paper with a coating thickness of 0.1-0.2mm , dried at 115-125°C for 2.5-5min to obtain a surface layer composite film; uniformly coat the solvent-free polyurethane adhesive layer slurry on the obtained surface layer composite film, and adjust the pH value of the adhesive layer slurry to If it is greater than 7, the thickness of the coating is 0.2-0.4mm, and it is dried at 120-130°C for 2-3 minutes, and the coating retains a certain degree of adhesion; the polylactic acid-treated base cloth is attached to the obtained adhesive layer, and then dried at 130-130°C Dry at 140°C for 2-3 minutes, peel off the release paper after drying and aging, and obtain a solvent-free polylactic acid bio-based polyurethane...

Embodiment 1

[0043] Coat the water-based polyurethane surface layer slurry on the release paper, the coating thickness is 0.1mm, and dry at 115°C for 2.5min to obtain a surface layer composite film; wherein, the water-based polyurethane surface layer slurry in this embodiment is composed of parts by mass Consists of 100 parts of polyurethane water-based surface layer resin, 0.5 part of anti-yellowing additive, 2 parts of nano-layered compound wear-resistant additive, 1 part of Henchenke H-1008, and 1 part of color paste.

[0044] Uniformly coat the PH value of the solvent-free polyurethane adhesive layer slurry on the obtained surface layer composite film, the coating thickness is 0.2mm, and dry at 120°C for 2min, and the coating retains a certain degree of adhesion; among them, this implementation The example solvent-free polyurethane adhesive layer slurry is composed of 100 parts by mass of polylactic acid polyol, 50 parts of isocyanate, 0.15 part of organic bismuth catalyst and 0.3 part ...

Embodiment 2

[0051] Coat the water-based polyurethane surface layer slurry on the release paper with a coating thickness of 0.2mm, and dry at 125°C for 5min to obtain a surface layer composite film; wherein, the water-based polyurethane surface layer slurry in this embodiment is obtained by mass parts It is composed of 100 parts of polyurethane water-based surface layer resin, 1 part of anti-yellowing additive, 4 parts of nano-layered compound wear-resistant additive, 3 parts of Henchenke H-1008, and 5 parts of color paste.

[0052] Uniformly coat the PH value of the solvent-free polyurethane adhesive layer slurry on the obtained surface layer composite film, the coating thickness is 0.4mm, and dry at 130°C for 3 minutes, and the coating retains a certain degree of adhesion; among them, this implementation The example solvent-free polyurethane adhesive layer slurry is composed of 100 parts by mass of polylactic acid polyol, 70 parts of isocyanate, 0.2 part of organotin catalyst and 0.4 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile load | aaaaa | aaaaa |

| Tear load | aaaaa | aaaaa |

| Peel load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com