Preparation method and application of polyphyllin nano-liposome dry powder inhalation

A technology of nano-liposome and polyphyll saponin, which is applied in the direction of liposome delivery, nanotechnology, nanotechnology, etc., can solve the problems of liposomes that are prone to oxidation, storage intolerance, and poor stability, and improve the therapeutic index , convenient transportation, and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation of embodiment 1 saponin VI nano liposome powder spray

[0046] Prepare papaya saponin liposomes by ethanol injection method, with a fixed drug-to-lipid ratio of 1:10, that is, take 270mg of hydrogenated soybean lecithin and 30mg of cholesterol dissolved in 10ml of absolute ethanol as the organic phase, take 30mg of papaya saponin VI, and 30mg of manna Alcohol was dissolved in 30 ml of phosphate buffer (pH 7.4, 0.01M) as the aqueous phase. Slowly add the organic phase to the water phase at a constant temperature of 50°C, stir for 10 minutes, mix evenly, and continue to stir until the ethanol is completely volatilized. The powder spray is prepared by spray drying. The specific process conditions are: Concentrate the heavy building with a rotary evaporator Saponin VI nano-liposomes, taking soluble solids as an index, are concentrated to the concentration (16wt%) of the concentrated solution required for spray drying. Based on 200ml of concentrated liquid, ...

Embodiment 2

[0049] The preparation of embodiment 2 saponins VI nano liposome powder spray

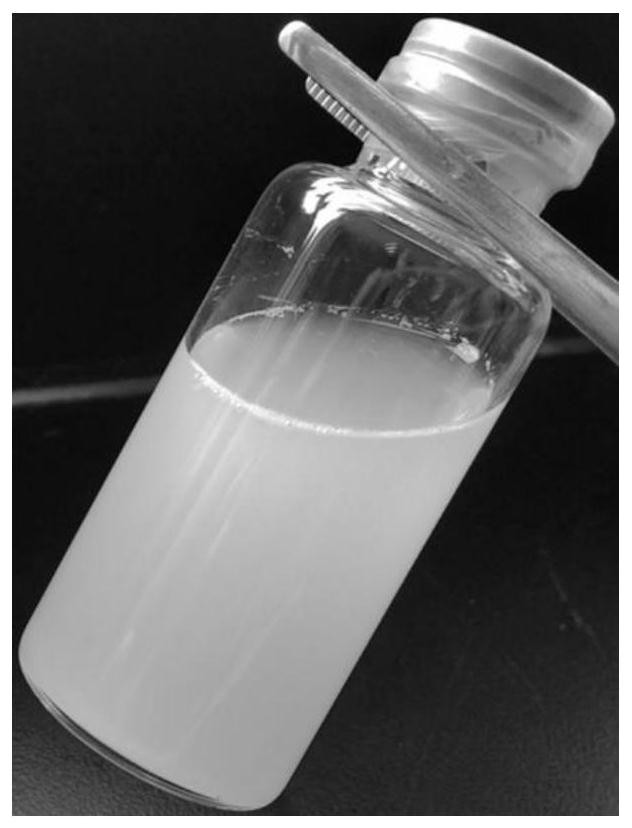

[0050] Prepare papaya saponin VI liposomes by solvent injection method: use ethyl acetate: ethanol (1: 1, v: v) as solvent, fixed drug lipid ratio is 1: 10 (mass ratio), hydrogenated soybean lecithin: cholesterol : Stearylamide (1: 1: 0.1, mass ratio) is used as lipid component, is dissolved in 5~10ml solvent as organic phase, gets 30mg pagoda saponin, and 30mg mannitol is dissolved in 30ml phosphate buffer (pH7. 4, 0.01M) as the aqueous phase. Slowly add the organic phase to the water phase whose temperature has been kept at 50°C, stir for 10 minutes, mix evenly, and continue stirring until the ethanol is completely volatilized, and then the nanoliposomes of papaya saponin VI are obtained, see image 3 ;Adopt the freeze-drying method to prepare the powder spray, and its process conditions are: use lactose and mannitol 1:1 (mass ratio) as the freeze-drying protective agent, use 10% as the drying a...

Embodiment 3

[0052] The preparation of embodiment 3 saponin VI nano liposomes

[0053] Prepare papaya saponin VI liposomes by ethanol injection method, that is, take 400mg hydrogenated soybean lecithin, 50mg cholesterol dissolved in 10ml absolute ethanol as the organic phase, take 50mg paprika saponin VI, 50mg mannitol and dissolve in 50ml phosphate buffer (pH7.4, 0.01M) as the aqueous phase. Slowly add the organic phase to the water phase whose temperature has been kept at 50°C, stir for 10 minutes, mix evenly, continue to stir until the ethanol is completely volatilized, and freeze-dry to obtain the nanoliposome powder of saponin VI precursor; use Box-Behnken The test optimized the main factors affecting the encapsulation efficiency of papaya saponin, the factors were ethanol quality (X1), hydrogenated soybean lecithin quality (X2), cholesterol quality (X3), and carried out the central combination design of factor level. Taking the encapsulation rate as an index, the experiment was arra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Electric potential | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com