Preparation method of polyacrylic acid oil-absorbing resin and product thereof

A technology of oil-absorbing resin and polyacrylic acid, which is applied in the field of oil-absorbing resin, can solve the problems of reduced oil absorption performance, slow adsorption efficiency, and low oil absorption ratio, and achieve good oil-water selectivity, controllable and adjustable structure, and improved separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

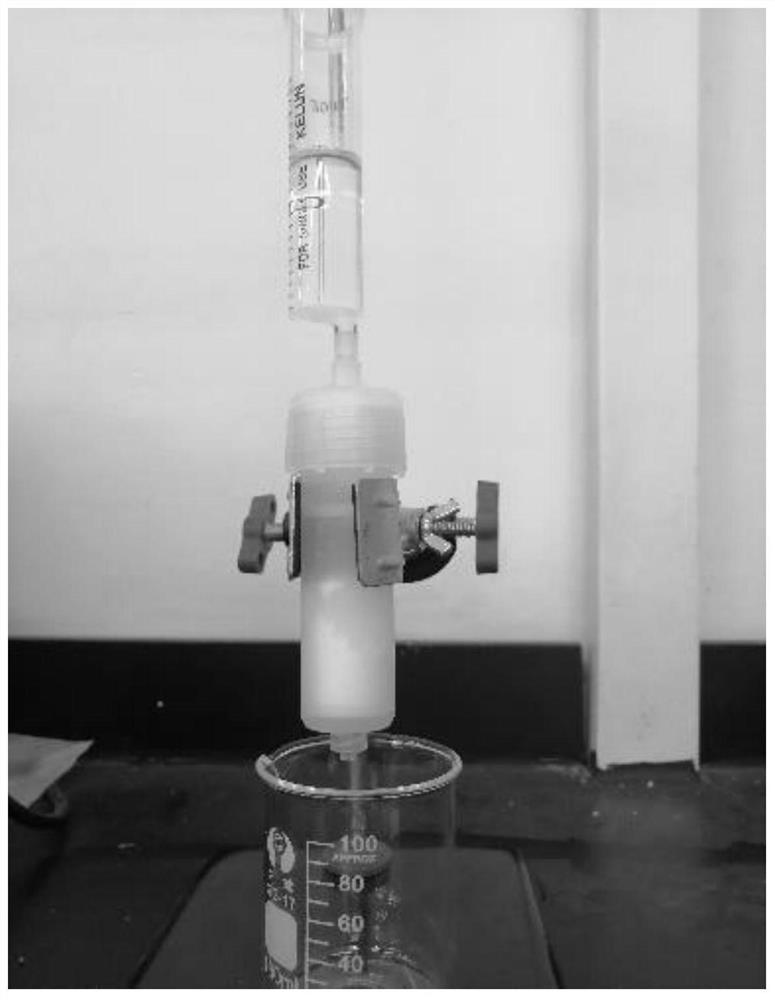

Image

Examples

Embodiment 1

[0040] (1) Accurately measure 5 mL of trimethylolpropane, then add 1 mL of concentrated sulfuric acid (mass fraction of concentrated sulfuric acid ≥ 70%), and add 20 mL of acrylic acid when the system is cooled to room temperature after exothermic heat is completed. After heating to carry out reflux reaction for 3 hours, wash with saturated sodium carbonate solution to remove concentrated sulfuric acid, trimethylolpropane and acrylic acid, and dry with anhydrous potassium carbonate to obtain a resin skeleton core precursor.

[0041] (2) Dissolve 200mL of acrylic acid in 50mL of ultrapure water, add 10mL of the precursor synthesized in the first step, add dodecylbenzenesulfonic acid as an emulsifier, and fully stir with a spiral stirrer. After the system turns milky white, add 0.1g of oil-soluble initiator azobisisobutyronitrile, heat up to 70°C and stir for inverse emulsion polymerization for 60 minutes to obtain a polyacrylic acid resin skeleton, and use gel chromatography to ...

Embodiment 2

[0044](1) The original soil of attapulgite is roasted at 350°C for 4 hours, crushed to pass through a 100-mesh sieve, and soaked in 0.05mol / L sulfuric acid solution for 20 minutes (the mass-volume ratio of attapulgite to acidic solution is 10g: 30mL), Then take it out and directly transfer it to 1.5mol / L sodium hydroxide solution for soaking for 10 minutes (the mass volume ratio of attapulgite and acidic solution is 10g:30mL), wash with water until neutral, and dry at 50°C to obtain modified attapulgite.

[0045] (2) Accurately measure 5mL of trimethylolpropane, then add 1mL of concentrated sulfuric acid, and add 20mL of acrylic acid when the system is cooled to room temperature after exothermic. After heating to carry out reflux reaction for 3 hours, wash with saturated sodium carbonate solution to remove concentrated sulfuric acid, trimethylolpropane and acrylic acid, and dry with anhydrous potassium carbonate to obtain a resin skeleton core precursor.

[0046] (3) Dissolve ...

Embodiment 3

[0049] Same as Example 2, the difference is that the alkali modification process of attapulgite is omitted, and the attapulgite after roasting and acid modification is used as the loading material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com