Rapid and simple preparation method of lignin-based carbon quantum dots with high quantum yield

A technology based on carbon quantum and lignin, which is applied in the field of fluorescent carbon quantum dot preparation, can solve the problems of low fluorescence quantum yield of products, inability to prepare in large quantities, and complicated preparation process, so as to achieve cheap and easy-to-obtain materials and benefit large-scale production. Scale promotion, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

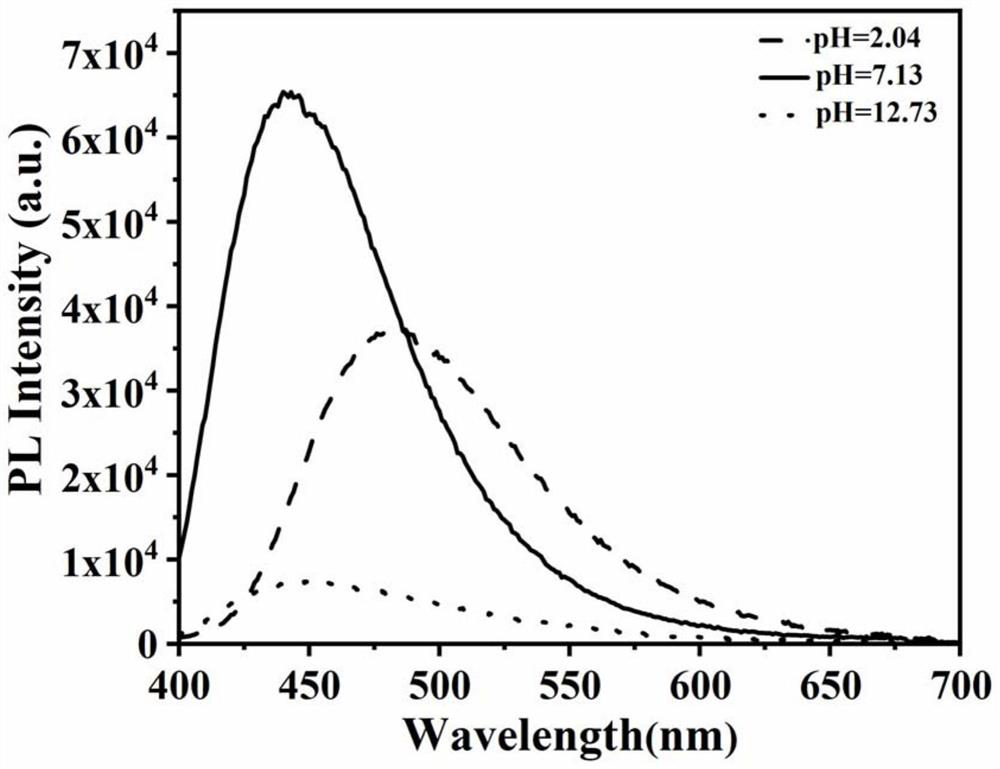

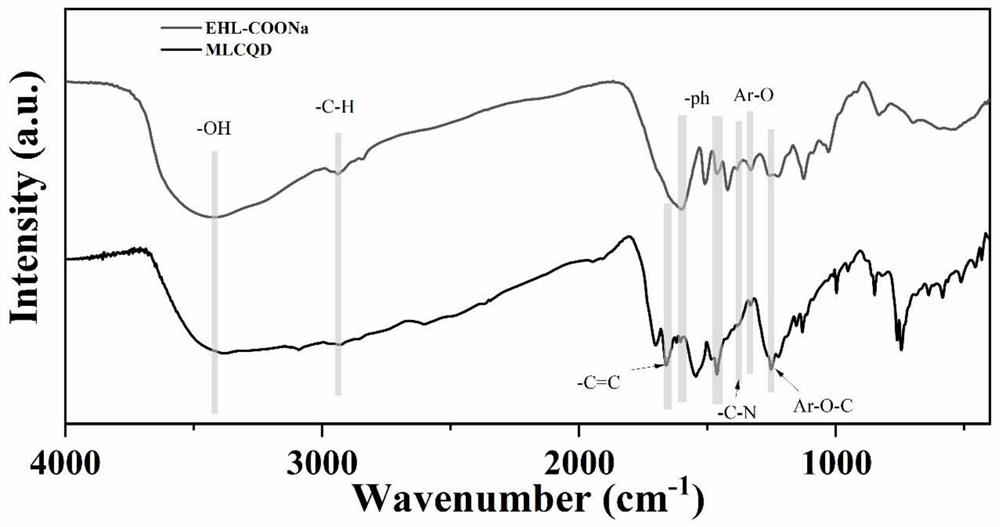

[0033]Dissolve 10g of Longli enzymatic lignin in an alkaline solution, add 6g of monochloroacetic acid dropwise, and heat at a constant temperature for 90 minutes. After the reaction, adjust the pH to acidic to precipitate the modified lignin, centrifugally wash, and dry for later use. Weigh 0.25 g of the obtained modified lignin and 10 g of citric acid, disperse them in 50 mL of ultrapure water under magnetic stirring, add 1.0 g of ethylenediamine, and disperse by ultrasonic oscillation for 15 min. After microwave reaction at 150° C. for 5 minutes, take it out, and naturally cool to room temperature, the crude product of lignin carbon quantum dots is obtained; the crude product is centrifuged, filtered through a filter membrane, and the filtrate is collected. After the filtrate was purified by dialysis with a 5000 Da specification dialysis bag, a lignin-based carbon quantum dot solution was obtained, and its quantum yield was measured to be 56.82%. The lignin-based carbon qua...

Embodiment 2

[0035] Dissolve 10g of bioleborin lignin in an alkaline solution, add 6g of sodium hypochlorite dropwise, and heat at a constant temperature for 90 minutes. After the reaction, adjust the pH to acidic to precipitate the modified lignin, centrifuge and wash, and dry for later use. Weigh 0.5 g of the obtained modified lignin and 10 g of citric acid, disperse them in 50 mL of ultrapure water under magnetic stirring, add 0.5 g of o-phenylenediamine, and disperse by ultrasonic oscillation for 5 min. Then microwave reaction at 150° C. for 20 minutes, take it out, and naturally cool to room temperature to obtain a crude product of lignin carbon quantum dots; centrifuge the crude product, filter it through a filter membrane, and collect the filtrate. After the filtrate was purified by dialysis with a 3000Da specification dialysis bag, a lignin-based carbon quantum dot solution was obtained, and the measured quantum yield was 64.49%. The lignin-based carbon quantum dot solution is rota...

Embodiment 3

[0037] Dissolve 10g of Shanghai Yunzhe alkali lignin in alkaline solution, add 6g of sodium bromide dropwise, and heat at a constant temperature for 90min. After the reaction, adjust the pH to acidic to precipitate the modified lignin, centrifuge and wash, and dry for later use. Weigh 0.5 g of the obtained modified lignin and 1.5 g of glycolic acid, disperse them in 20 mL of ultrapure water under magnetic stirring, add 1 g of urea, and disperse with ultrasonic oscillation for 20 min. Then microwave reaction at 200° C. for 30 minutes, take it out, and naturally cool to room temperature to obtain a crude product of lignin carbon quantum dots; centrifuge the crude product, filter it through a filter membrane, and collect the filtrate. After the filtrate was dialyzed and purified with a 500 Da specification dialysis bag, a lignin-based carbon quantum dot solution was obtained, and its quantum yield was measured to be 42.53%. The lignin-based carbon quantum dot solution is rotative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com