Valuable metal extraction process suitable for electroplating sludge

A technology for valuable metals and electroplating sludge, which is applied in the direction of improving process efficiency, can solve the problems of unsatisfactory leaching rate of valuable metals, increased energy consumption, and difficulty in practical use, achieving cyclic enrichment, reducing dangerous properties, The effect of improving the leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Add sulfur and pyrite to the bioleaching regeneration tank, and add sulfur / iron oxidizing compound flora to obtain an active leachate, the pH of the active leachate is 0.8, the concentration of Fe3+ is 1000mg / L, and the concentration of Fe2+ is 500mg / , the solid-to-liquid ratio of the active leachate is 8%, the active leachate is pumped into the bioleaching extraction tank through a peristaltic pump, and the active leachate enters the bioleaching extraction tank through the membrane module In the process, the supernatant in the bioleaching regeneration tank can be pumped directly into the bioleaching extraction tank for extraction reaction, so as to improve the preparation reaction efficiency of the overall equipment, adding solid waste to the bioleaching extraction tank The material undergoes leaching reaction to complete the bioleaching of valuable metals. After the leaching reaction is completed, the mud-water mixture is introduced into a solid-liquid separation dev...

Embodiment 2

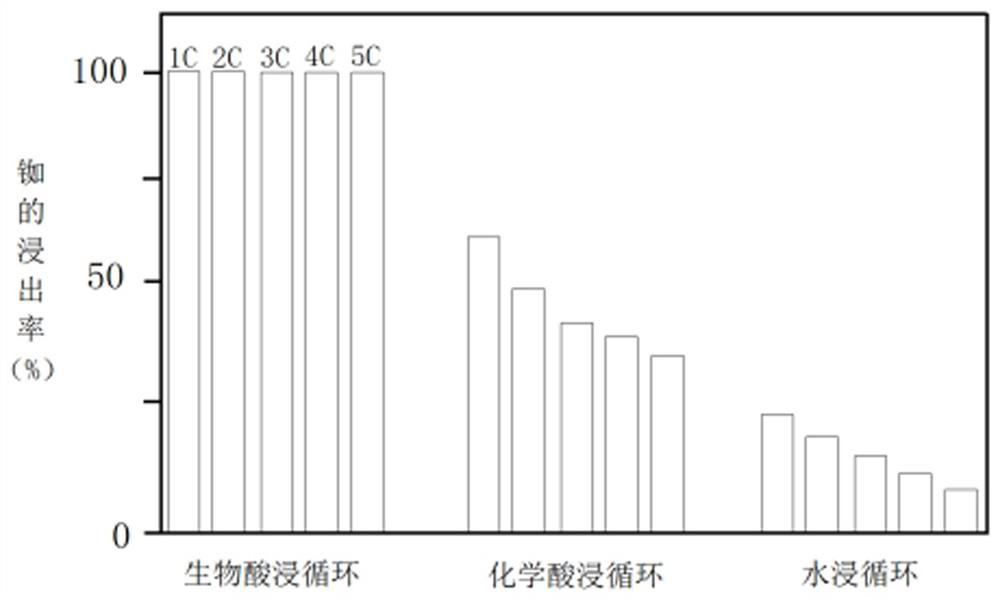

[0043] like figure 1 , the comparison of rubidium soot expensive metal rubidium bioleaching-cycle enrichment and sulfuric acid leaching-cycle enrichment performance is as follows:

[0044] The new technology of MBR bioleaching-circular enrichment can quickly extract-enrich the expensive metal rubidium in iron and steel smelting dust collection dust under the condition of 15% high solid-liquid ratio. Aqueous solution leaching-enrichment efficiency is compared, the results are shown in figure 1 . The new MBR bioleaching-circular enrichment process can realize the complete extraction of expensive metal rubidium in the soot, that is, the leaching rate is 100%, and the bioleaching efficiency (ie, the leaching rate) does not decay during the 5 cycles; the initial sulfuric acid leaching The efficiency is obviously lower than that of bioleaching, the leaching rate is about 80%, and the efficiency of sulfuric acid leaching continues to decline during the 5 cycles, the initial water l...

Embodiment 3

[0046] The performance comparison of oxide electroplating sludge bioleaching-circulation enrichment and sulfuric acid extraction-circulation enrichment is as follows:

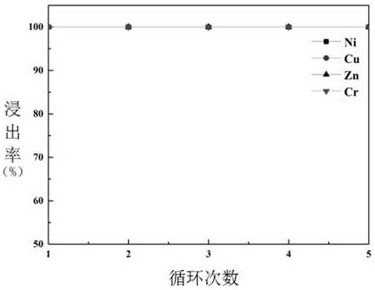

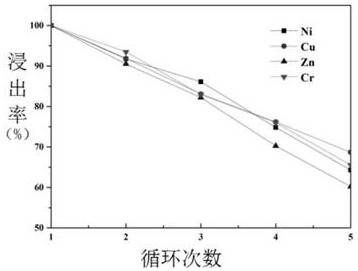

[0047] The new MBR bioleaching-circulation enrichment process rapidly extracts-highly enriches the valuable metals in the oxide electroplating sludge under the condition of 10% high solid-liquid ratio, and performs the same acidity as the sulfuric acid solution leaching-enrichment performance. compare, see figure 2 and image 3 . The research shows that the new MBR bioleaching-circulation enrichment process can realize the complete dissolution of four valuable metals copper, nickel, zinc, and chromium in oxide electroplating sludge, and the bioleaching efficiency does not decay during the five cycle processes; The initial sulfuric acid leaching efficiency was significantly lower than that of bioleaching, and the sulfuric acid leaching efficiency continued to decline during the five cycles, which made it diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com