Preparation method and application of SLIPS/LDHs composite film layer on surface of magnesium alloy

A composite film layer and magnesium alloy technology, which is applied to the device for coating liquid on the surface, metal material coating process, coating, etc., can solve the problems of complicated operation and high cost, and achieve firm combination, good universality, The effect of proactive protection intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for preparing a triple self-repairing SLIPS / LDHs composite film layer on the surface of a magnesium alloy, the specific steps are:

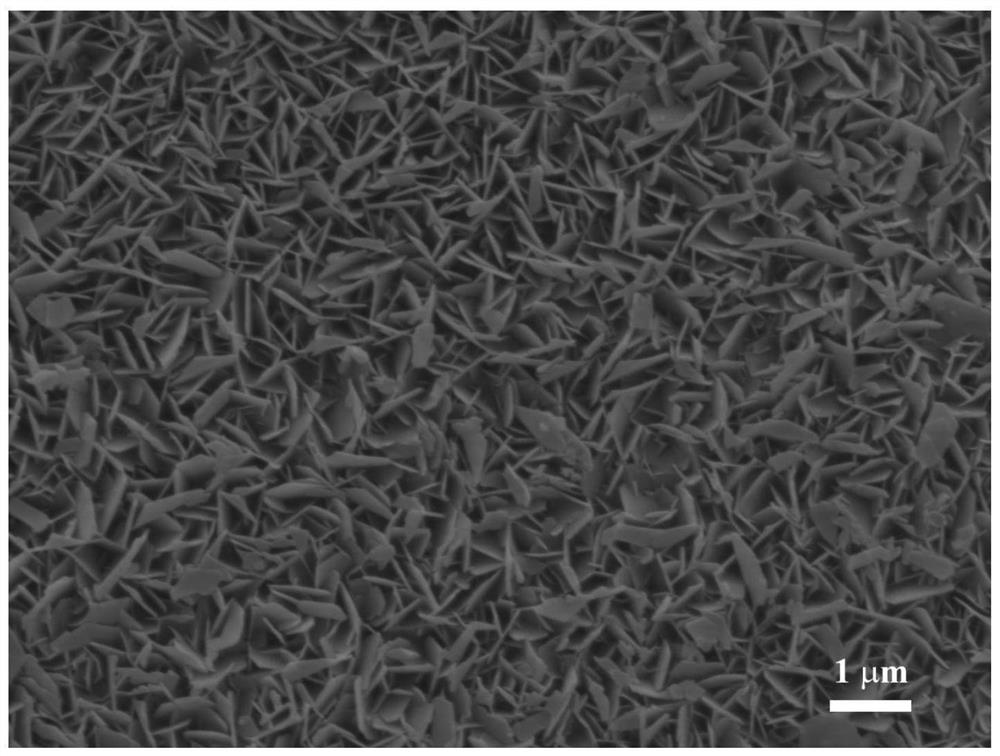

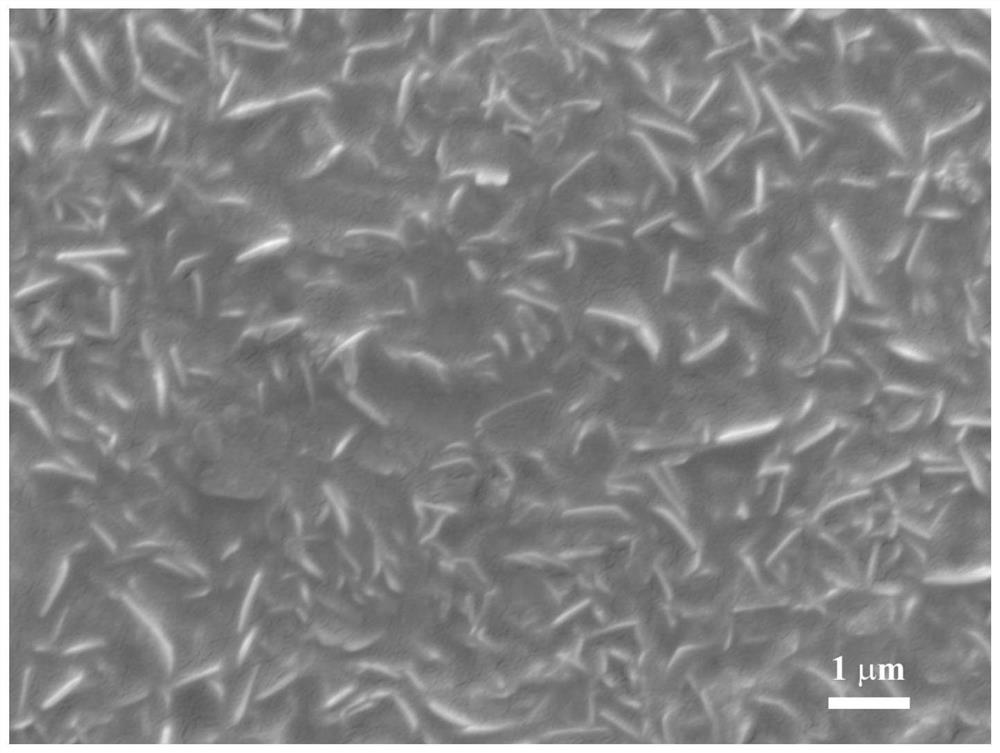

[0045] 1. In situ growth of MgAlLa-LDHs film layer

[0046]Soak the water-milled magnesium alloy AZ31 in the above-mentioned degreased and degreased aqueous solution (sodium hydroxide 40g / L, sodium carbonate 25g / L, sodium phosphate 40g / L), keep warm in a water bath at 50°C for 60s, and then wash with 1M hydrogen Wash with an aqueous solution of sodium oxide at 60°C for 30s, and then use 400g / L nitric acid (ρ=1.42g / ml) to polish at room temperature 25°C for 1-2min. Rinse again with deionized water and dry with cold air. (Water mill: Use 150, 600, 800, 1200, 2000# sandpaper to polish the magnesium alloy substrate respectively, and use alcohol to ultrasonically clean it for 5 minutes, then dry it for later use).

[0047] Hydrothermal reaction steps: first pour the electrolyte solution into the liner of the reaction kettle, and then...

Embodiment 2

[0056] A method for preparing a triple self-repairing SLIPS / LDHs composite film layer on the surface of a magnesium alloy, the specific steps are:

[0057] 1. In situ growth of MgAlLa-LDHs film layer

[0058] Soak the water-milled magnesium alloy AZ31 in the above-mentioned degreased and degreased aqueous solution (sodium hydroxide 40g / L, sodium carbonate 25g / L, sodium phosphate 40g / L), keep warm in a water bath at 50°C for 60s, and then wash with 1M hydrogen Wash with an aqueous solution of sodium oxide at 60°C for 30s, and then use 400g / L nitric acid (ρ=1.42g / ml) to polish at room temperature 25°C for 1-2min. Rinse again with deionized water and dry with cold air.

[0059] Hydrothermal reaction steps: first pour the electrolyte solution into the liner of the reaction kettle, and then put the cleaned magnesium alloy sample into the in-situ growth solution, the in-situ growth solution: sodium nitrate 0.1M, aluminum nitrate 0.05M, nitric acid Lanthanum 0.001M, pH 10.9; after ...

Embodiment 3

[0068] A method for preparing a triple self-repairing SLIPS / LDHs composite film layer on the surface of a magnesium alloy, the specific steps are:

[0069] 1. In situ growth of MgAlLa-LDHs film layer

[0070] Soak the water-milled magnesium alloy AZ31 in the above-mentioned degreased and degreased aqueous solution (sodium hydroxide 40g / L, sodium carbonate 25g / L, sodium phosphate 40g / L), keep warm in a water bath at 50°C for 60s, and then wash with 1M hydrogen Wash with an aqueous solution of sodium oxide at 60°C for 30s, and then polish with 400g / L nitric acid at room temperature 25°C for 1-2min. Rinse again with deionized water and dry with cold air.

[0071] Hydrothermal reaction steps: first pour the electrolyte solution into the liner of the reaction kettle, and then put the cleaned magnesium alloy sample into the in-situ growth solution, the in-situ growth solution: sodium nitrate 0.1M, aluminum nitrate 0.05M, nitric acid Lanthanum 0.001M, pH 10.9; after closing the rea...

PUM

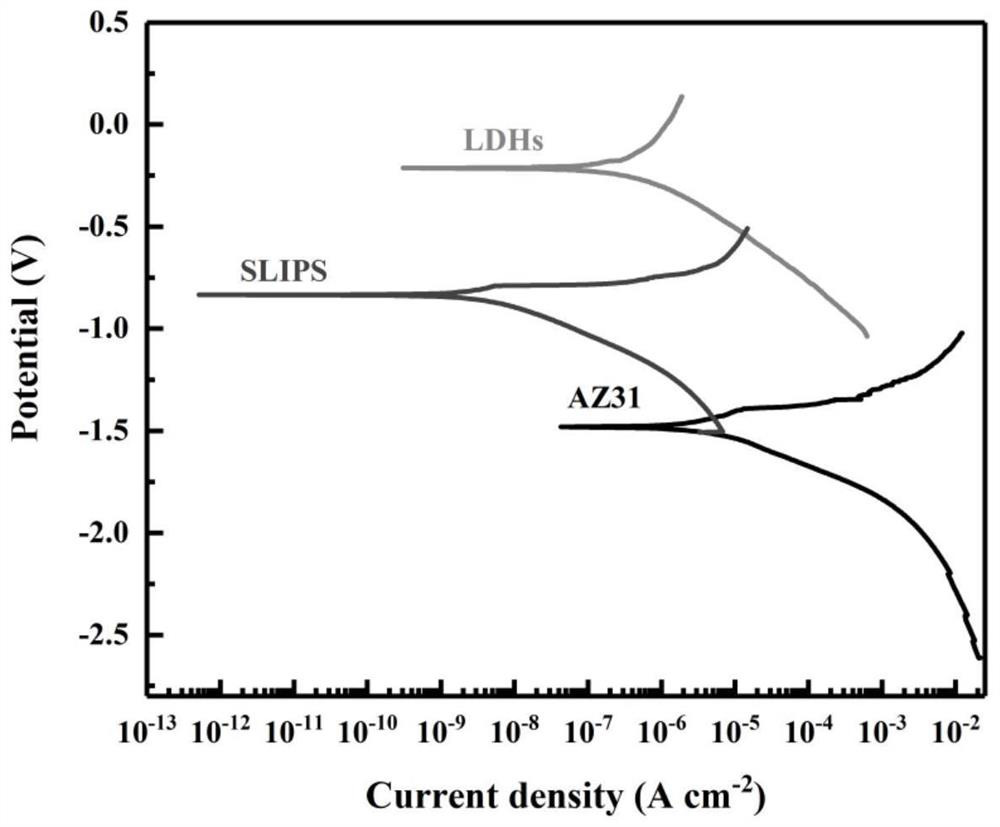

| Property | Measurement | Unit |

|---|---|---|

| Corrosion current density | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com