Ni-doped Ti3AlC2/Cu composite material for inhibiting decomposition of Ti3AlC2 and preparation method of Ni-doped Ti3AlC2/Cu composite material

A composite material and energy spectrum analysis technology, applied in the field of copper-based composite material preparation, can solve the problems that ceramics cannot give full play to their performance advantages, limit the promotion and application of materials, and the interface bonding strength is not high, so as to improve the mechanical properties of materials and significantly reduce holes , the effect of inhibiting pyrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention suppresses Ti 3 AlC 2 Ni-doped Ti for decomposition 3 AlC 2 The preparation method of / Cu composite material, comprises the following steps:

[0042] S1, the Ti 3 AlC 2 The powder, Ni powder and Cu powder are proportioned according to a certain composition ratio, and poured into a ball mill tank for ball milling;

[0043] Ti 3 AlC 2 The composition ratio of powder, Ni powder and Cu powder is: Ti 3 AlC 2 The powder composition is 10Vol.% to 45Vol.%, the Ni powder composition is 8Vol.% to 10Vol.%, and the Cu powder composition is 45Vol.% to 82Vol.%.

[0044] Ti 3 AlC 2 The particle size of the powder is 150-300 mesh, the purity is 97.5%-99.5%, and the shape and structure are irregular; the particle size of the Ni powder is 250-325 mesh, the purity is 98.5%-99.9%, and the water atomized spherical powder; the Cu powder The particle size is 325-400 mesh, the purity is 98.5%-99.9%, and it is water-atomized spherical powder.

[0045] The mill...

Embodiment 1

[0056] Ti 3 AlC 2 Ni-doped Ti with a content of 10Vol.% 3 AlC 2 / Cu composite material pantograph slide plate

[0057] 1) First, 10Vol.% Ti 3 AlC 2 Powder, 8Vol.% Ni powder and 82Vol.% Cu powder are mixed and poured into a ball mill jar for ball milling; Ti 3 AlC 2 The particle size of the powder is 150 mesh, the purity is 97.5%, and the shape structure is irregular; the particle size of the Ni powder is 250 mesh, the purity is 98.5%, and the water atomized spherical powder; the particle size of the Cu powder is 325 mesh, the purity is 98.5%. Water atomized spherical powder. The ball milling parameters are: the volume of the ball milling tank is 0.5L, the ball milling time is 1 hour, the ball milling speed is 150, the ball-material ratio (mass ratio) is 5:1, the process control agent is ethanol solution, and the process control agent ratio is 1:1, The grinding ball is made of agate grinding ball.

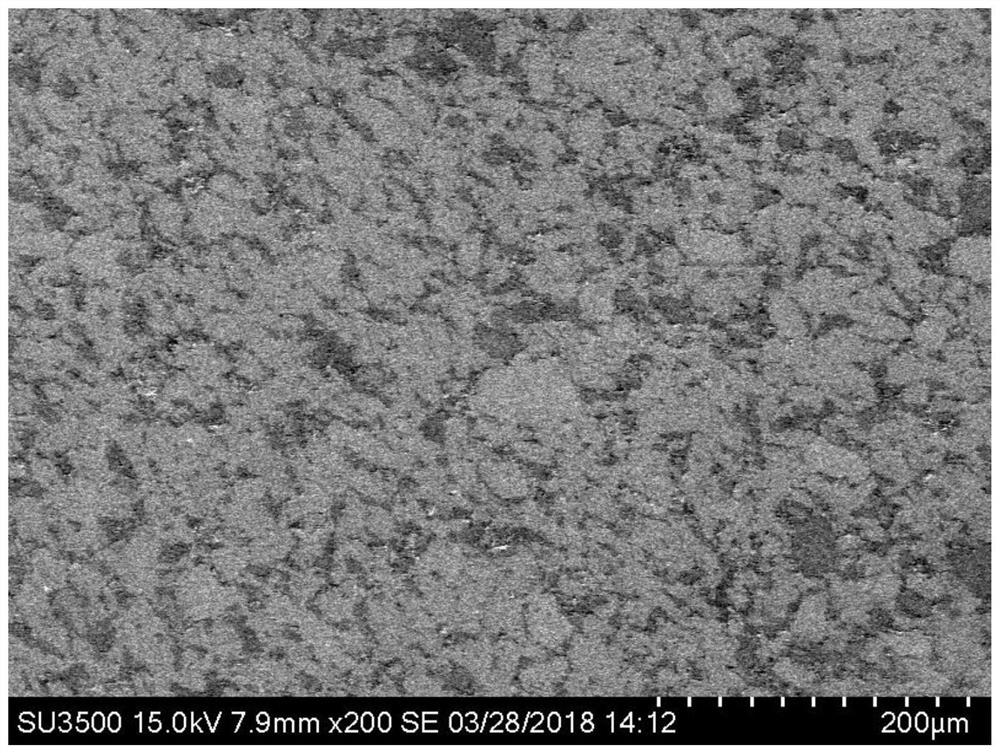

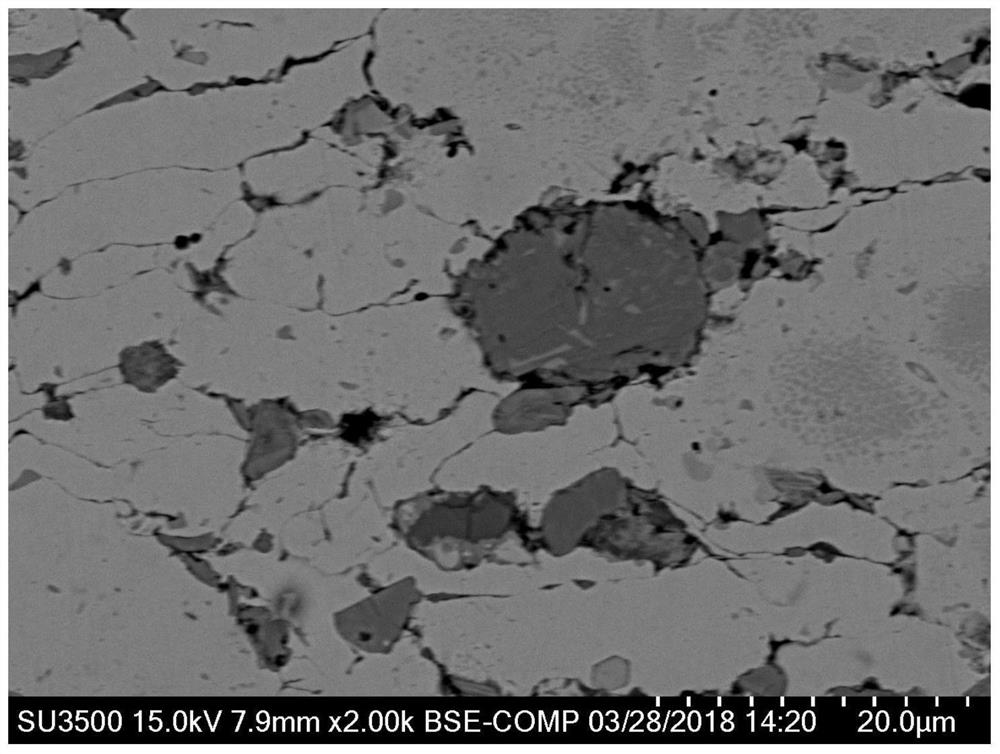

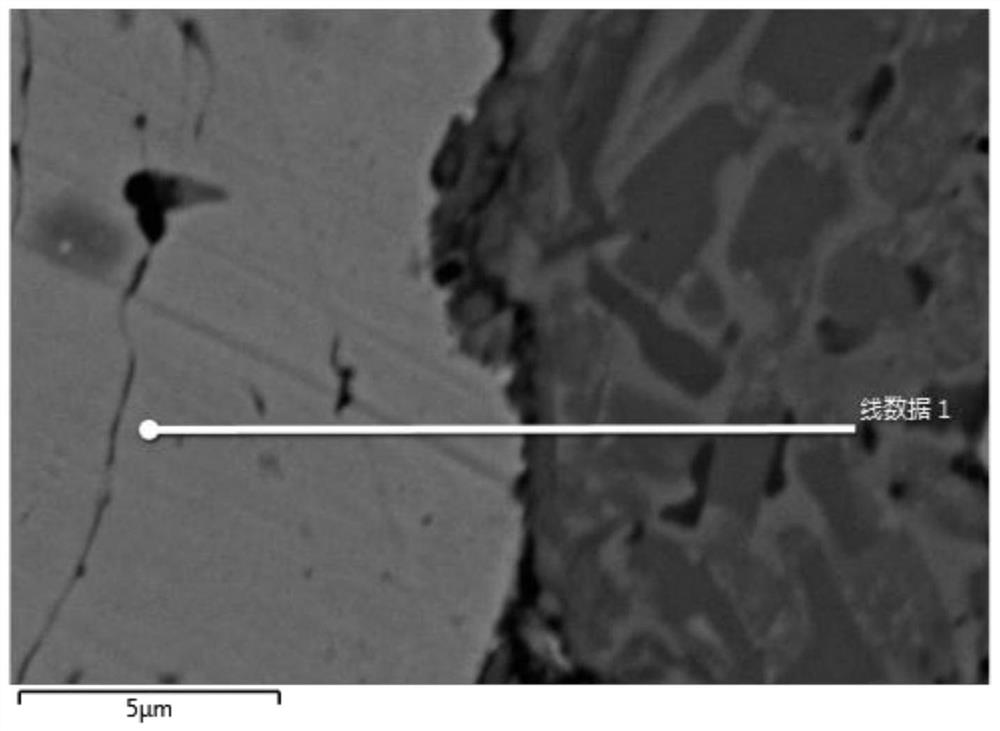

[0058]2) Perform EDS energy spectrum analysis on the ball-milled powde...

Embodiment 2

[0062] Ti 3 AlC 2 Ni-doped Ti with a content of 25Vol.% 3 AlC 2 / Cu composite electrical contacts

[0063] 1) First, 25Vol.% Ti 3 AlC 2 Powder, 8.5Vol.% Ni powder and 66.5Vol.% Cu powder are mixed and poured into a ball mill jar for ball milling; Ti 3 AlC 2 The particle size of the powder is 200 mesh, the purity is 98.5%, and the shape structure is irregular; the particle size of the Ni powder is 325 mesh, the purity is 99.5%, and the water atomized spherical powder; the particle size of the Cu powder is 400 mesh, the purity is 99.5%. Water atomized spherical powder. The ball milling parameters are: the volume of the ball milling tank is 1L, the ball milling time is 2 hours, the ball milling speed is 200rpm, the ball-to-material ratio (mass ratio) is 8:1, the process control agent is ethanol solution, and the process control agent ratio is 1:1. The ball is made of agate mill ball.

[0064] 2) Perform EDS energy spectrum analysis on the ball-milled powder to observe wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com