High-weather-resistance finish paint for protecting ship composite material and preparation method thereof

A composite material and high weather resistance technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of weak oxidation resistance, insufficient density, poor salt spray resistance, etc., and achieve good environmental protection, simple steps, and good film-forming properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Preparation method of high retreat of ship composite material protection, including the following steps:

[0023] Step (1), according to the number of parts, respectively, 80-100 parts of the modified epoxy silicone resin, 1-3 parts of the BYK110 and 1-2.5 parts of organic bentonifier are placed in the bucket, and Among them, 7.5-12.5 parts of xylene was added, and then the resulting mixed material was placed in a dispersion, and the dispersion treatment was performed under the rotational speed of 700-1000 R / min, and dispersing a dispersion A, spare;

[0024] Step (2), according to the weight of the weight, 15-20 parts of the amine curing agent and 20-60 parts of mica powder were sequentially added to the dispersion prepared by the step (1), and at 1200-1500R / min Decomposition treatment under the speed of rotation 20-40 min, dispersion B, spare;

[0025] Step (3), the dispersion B obtained by step (2) is transferred in the grinder to grind the material particle diameter...

Embodiment 1- Embodiment 4

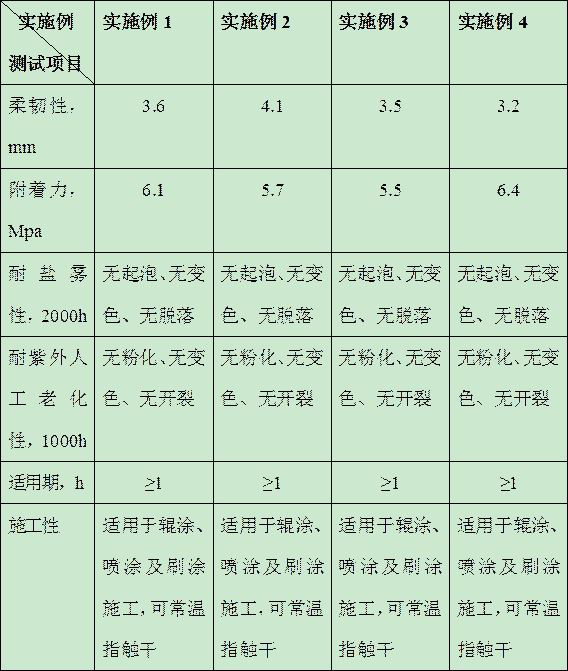

[0030] The composite material of the present invention is a normal temperature finger dry double-component weather resistant coating, and the coating can be applied with a variety of processes such as spraying, brush coating, roll coating. The thickness of each coating is 50 μm, coating The number of layers is 2-4. The specific ingredients of the embodiments are shown in the table below.

[0031] Table 1 Example 1- Example 4 ingredient table

[0032]

Embodiment 1

[0034] Example 1 A high retreat of a high retreat of a ship composite material, including the following steps:

[0035] Preparation of primary bov-modified epoxy silicone resin resin

[0036] A, according to the ratio of 1 g / 2 mL, the epoxy silicone resin and xylene solvent were placed in a reactor with magnetic stirring, and the epoxy resin dilution was prepared.

[0037] At room temperature, according to the ratio of isocyanate and epoxy silicone resin of 1 mol / 20g, the isocyanate obtained by brushing the reactant is slowly added to the step (1) prepared, in the continuous stirring conditions, The polymerization was carried out in a 120 ° C temperature environment for 3 h, and then the resulting reaction product was warmed to 140 ° C to remove xylene solvent treatment, and an epoxy prepolymer was produced.

[0038] C According to the ratio of 1 g / 12 mL, it is placed in a reactor with a mechanical stirred reactor, and after the ultrasonic dispersion is treated, and after the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com