Functional structural oil as well as preparation method and application thereof

A technology of functional structure and oil, applied in the field of edible oils and fats, can solve the problems of complex operation, no optimized structural fat, no literature reports, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

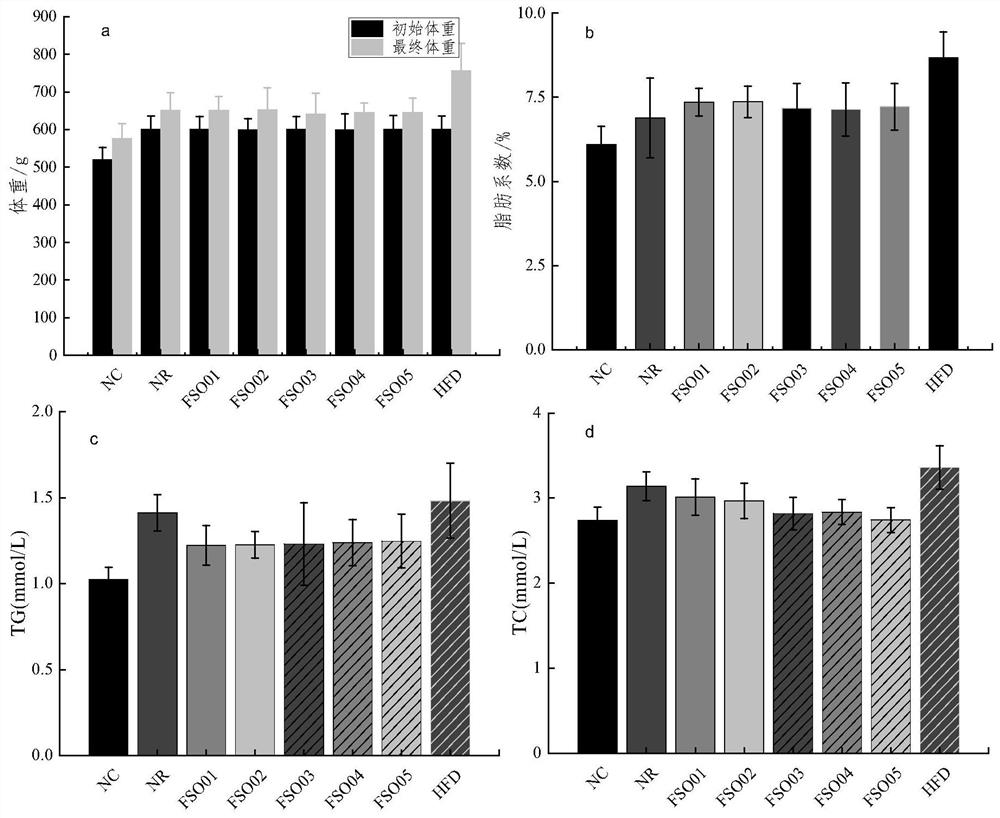

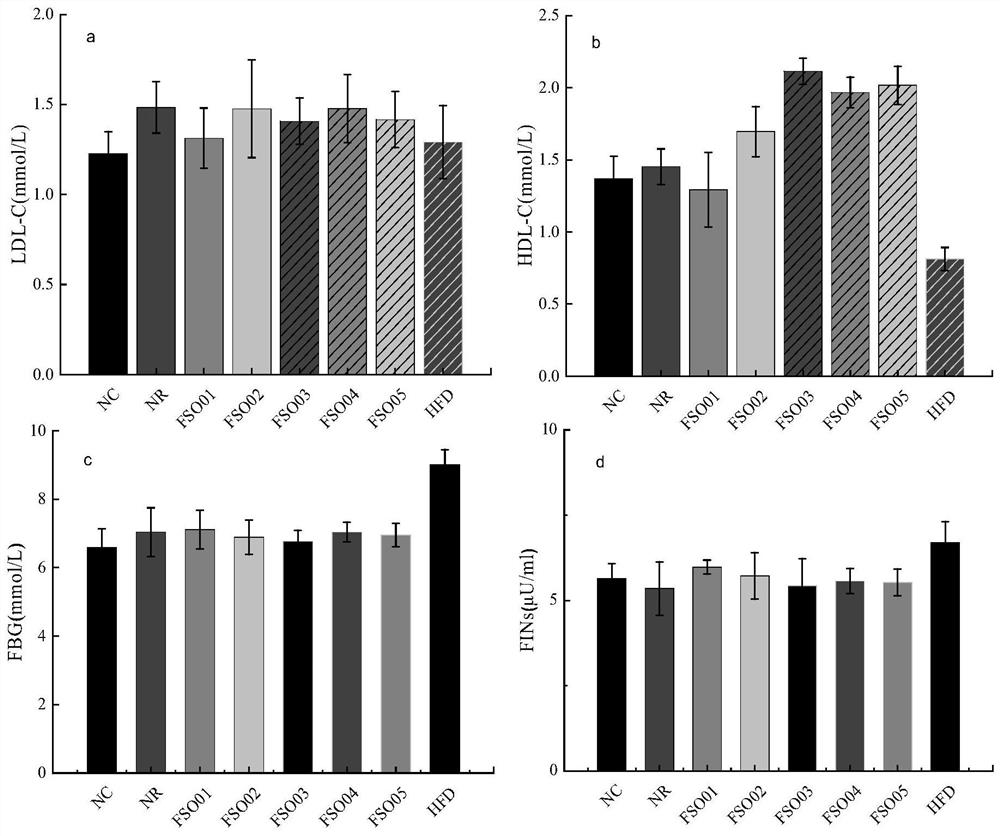

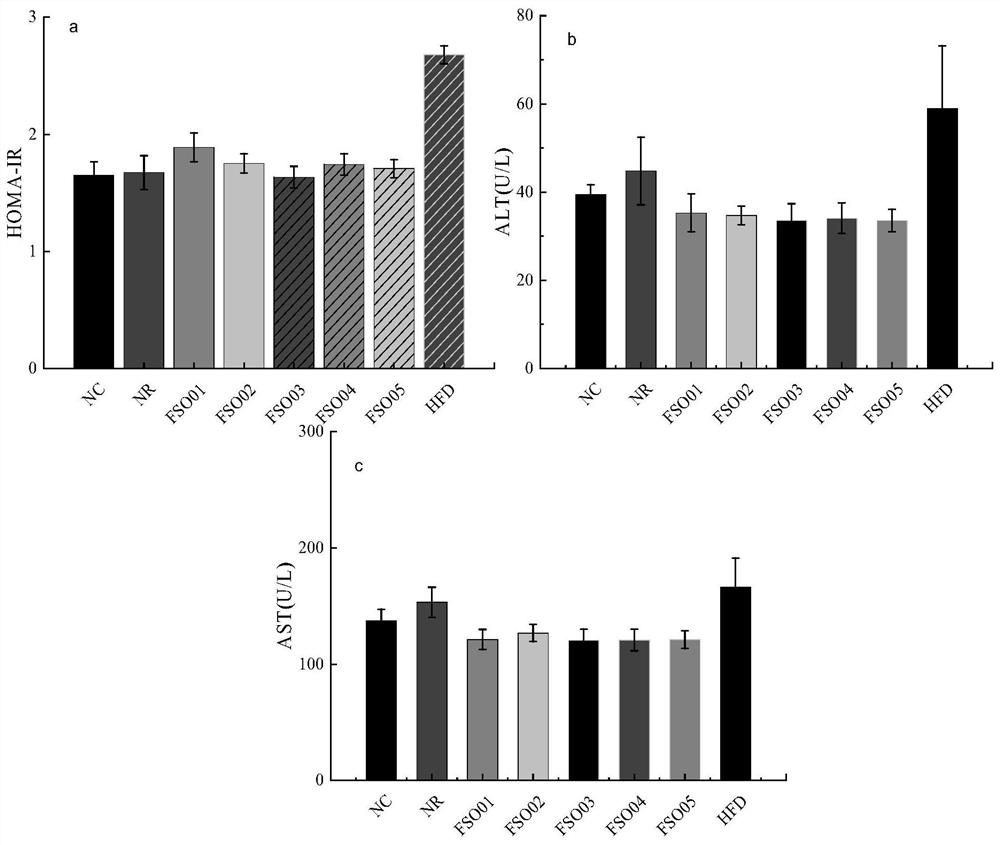

Embodiment 1

[0066]The camphor tree seed kernel oil, glyceryl caprylate, soybean oil, and fatty acid of linseed oil raw materials used in this embodiment are raw materials, and the composition thereof is shown in Table 2 for details. According to the mass ratio of caprylic acid glyceride to camphor tree seed oil is 3:7, 4:6, 5:5, 6:4, 7:3, the molar ratio of medium-chain fatty acid to long-chain fatty acid is 2 and the ratio of linolenic acid to linolenic acid The molar ratio of oleic acid is 2, respectively weigh appropriate amount of camphor tree seed oil, caprylic glycerides, soybean oil and linseed oil in different esterification reactors, and add fat according to 10% (w / w) of the mixed oil quality enzyme. The reaction temperature is 60°C, and the stirring reaction time is 8h. After the quaternary transesterification reaction, the lipase in the reaction solution was separated, and after molecular distillation and purification, the structural ester content was measured, and the mass ra...

Embodiment 2

[0083] In this example, according to the mass ratio of glyceryl caprylate and camphor tree seed kernel oil as 5:5, the molar ratio of medium-chain fatty acid to long-chain fatty acid as 2 and the molar ratio of linolenic acid to linoleic acid as 2, weigh 35.31 G of caprylic glycerides, 35.31g of camphor tree seed oil, 6.07g of safflower seed oil and 52.18g of perilla seed oil in the reactor. Quaternary transesterification reaction conditions are: lipase 10% (percentage of mixed oil mass), magnetic stirring (stirrer 30mm×10mm, rotating speed 100rpm), reaction temperature is 60°C, and reaction time is 8h.

[0084] After the reaction, the target product was obtained by molecular distillation, and the structural ester content was determined to be 97.69% by HPLC-ELSD detection method.

Embodiment 3

[0086]In this example, according to the mass ratio of glyceryl caprylate and camphor tree seed kernel oil as 5:5, the molar ratio of medium-chain fatty acid to long-chain fatty acid as 2 and the molar ratio of linolenic acid to linoleic acid as 2, weigh 35.89 The caprylic glyceride of g, the camphor seed kernel oil of 35.89g, the corn oil of 7.03g and the perilla seed oil of 52.18g are in the reactor. Quaternary transesterification reaction conditions are: lipase 10% (percentage of mixed oil mass), magnetic stirring (stirrer 30mm×10mm, rotating speed 100rpm), reaction temperature is 60°C, and reaction time is 8h.

[0087] After the reaction, the target product was obtained by molecular distillation, and the structural ester content was determined to be 98.01% by HPLC-ELSD detection method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com