Modified vanadium dioxide composite film and preparation method thereof

A technology of vanadium dioxide and composite thin film, which can be used in coatings, luminescent coatings, etc., can solve problems such as the brownish yellow stability of vanadium dioxide-based smart glass coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

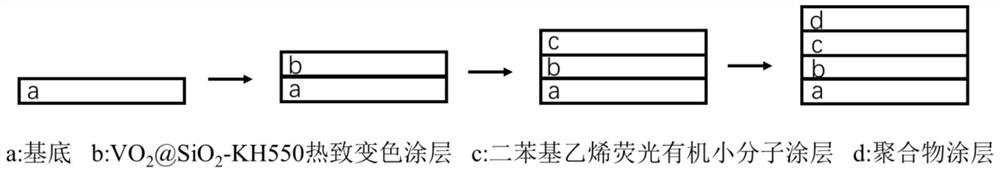

[0041] Take the resulting VO 2 @Sio 2 -KH550 hot discoloration material is dispersed into 10 mL of ethanol, and 1.0 g of polyvinyl butyrahyandehyde is added, and the mixed slurry is formed, and the rod is applied to the glass substrate, and the temperature is cured. VO 2 @Sio 2 -KH550 thermochromic monolayer membrane.

[0042] 0.03 g of 4,4'-bis (2-methoxystyrene) biphenyl is dissolved in 10 ml of dichloromethane, and 1.0 g of polyvinyl butyral butyraldehyde, stirring forms a uniform slurry, coated with roll Apply it to the above VO 2 @Sio 2 -Kh550 hot color changing film, room temperature curing, VO 2 @Sio 2 -KH550 / diphenylthylene fluorescent organic small molecule double composite film.

[0043] 0.6 g of polyvinyl alcohol was dissolved in 10 ml of deionized water, and the uniform slurry was stirred, and the rod was applied to the double composite film, cured at room temperature, VO 2 @Sio 2 -KH550 / Diphenylidene fluorescent organic small molecule / polymer three-layer composi...

Embodiment 2

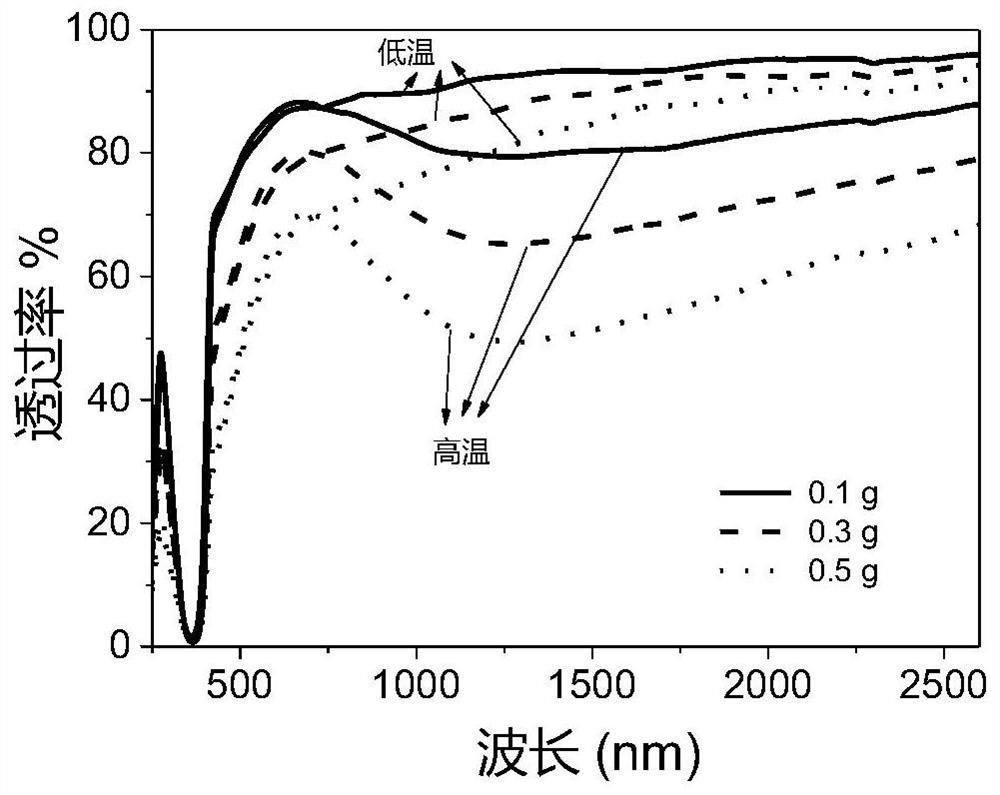

[0045] 0.1g, 0.3g, 0.5g VO, respectively 2 @Sio 2 -KH550 powder is dispersed into 10 mL of ethanol, and then 1.0 g of polyvinyl butyral, stirring forms a uniform slurry, applied to the glass substrate with roller, and concentrates different VO. 2 @Sio 2 -Kh550 hot discoloration film.

[0046] 0.03 g of 4,4'-bis (2-methoxystyrene) biphenyl is dissolved in 10 ml of dichloromethane, and 1.0 g of polyvinyl butyral butyraldehyde, stirring forms a uniform slurry, coated with roll Apply it to the above VO 2 @Sio 2 -KH550 hot-changing film, room temperature, double-layer composite film having different heat insulation effects.

[0047] 0.6 g of polyvinyl alcohol was dissolved in 10 ml of deionized water, and a uniform slurry was stirred, and it was applied to the double composite film with a roller, and the thermal insulation effect was different. VO 2 @Sio 2 -KH550 / Diphenylidene fluorescent organic small molecule / polymer three-layer composite film. The composite film of three differe...

Embodiment 3

[0049] Preparation according to Example 1 2 @Sio 2 -KH550 thermal discoloration monolayer film;

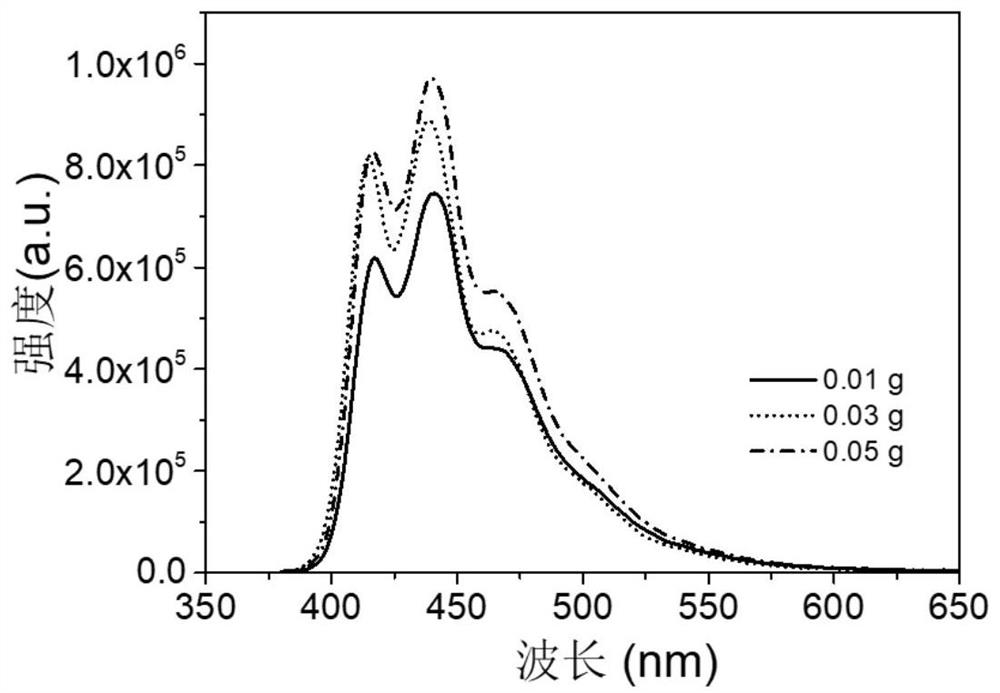

[0050] 0.01 g, 0.03 g, 0.05 g of 4,4'-double (2-methoxystyrene) biphenyl is dissolved in 10 ml of dichloromethane, and then 1.0 g of polyvinyl butyrahyandehyde, stirring is uniform. Slurry, coating different concentrations of sluries into the above VO, respectively. 2 @Sio 2 -KH550 thermally discolored film, room temperature, double-layer composite film having different luminous intensities.

[0051] 0.6 g of polyvinyl alcohol was dissolved in 10 ml of deionized water, and a uniform slurry was stirred, and the rod was applied to the double-layer composite film, and the luminous intensity was different. VO 2 @Sio 2 -KH550 / Diphenylidene fluorescent organic small molecule / polymer three-layer composite film. The emission spectrum of the three composite films was tested under 365 nm ultraviolet radiation. image 3 Indicated. from image 3 It can be seen that due to the amount of 4,4'-dou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com