Ceramic polishing grinding tool and preparation method thereof

A technology of ceramic polishing and abrasive tools, applied in grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems of insufficient toughness of bonding materials, uneven brick surface, large abrasive runout, etc., to achieve good appearance quality, Expand the degree of application and the effect of good buffering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

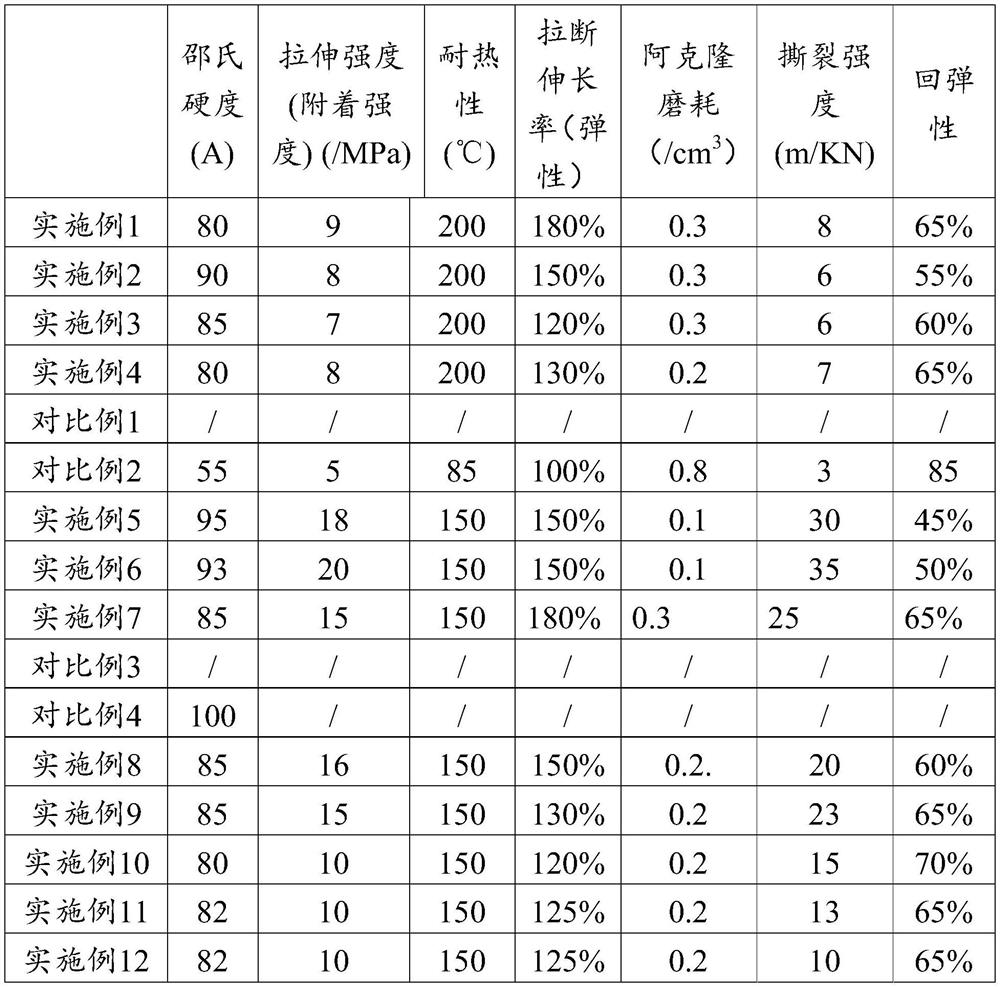

Examples

preparation example Construction

[0038] When a two-component silicone resin or two-component polyurethane resin is prepared, the preparation method of the abrasive contains includes the following steps:

[0039] A. Depending on the function, divide the elastic resin into two copies;

[0040] B. The first elastic resin is mixed with abrasives, and the filler is mixed, and the first mixture is obtained;

[0041] C. A second mixture is mixed with a wax, a functional auxiliary agent, and a first mixture to obtain a second mixture;

[0042] D, mount the second mixture into the mold and cooled after cure.

[0043] The elastic resin is divided into two components depending on the function, and there is a different role in the preparation process, and the addition of other impurities has good performance in avoiding the addition of other impurities.

[0044] When a reactant using a polyurethane resin is used as a material to prepare a raw material, the preparation method of the abrasive contains includes the following st...

Embodiment 1

[0050] The elastic resin binding agent in the abrasive tool in Example 1 selected a fed-form silicone rubber.

[0051] The abrasive tool in Example 1 was prepared by the following preparation method: 20 parts of the silicone rubber according to 20 parts of the liquid silicone rubber, 10 parts of 180 # diamond sand, 40 parts of 180 # green silicon carbide, 4 parts of chromium oxide poured into the stirring In the cylinder, stirring at a rate of 1000 rpm for 10 minutes, then 20 parts of the liquid silicone rubber curing agent B, 4.5 parts of liquid paraffin, 1 coupling agent, 0.5 parts of catalyst, and stirred by 1500 rpm / min. After the uniform slurry is formed in 5 minutes, it is poured into a mold for a long 13 cm, a deep 1.5cm, a width of 5.5 cm. After curing, after curing, then in addition to the 100 degree oven for 5 hours, and then demolded after cooling. Abrasive.

Embodiment 2

[0053] Example 2 The elastic resin binding agent in the abrasive was used to use the addition silicone rubber.

[0054] The abrasions in Example 2 were prepared by the following preparation methods: 10 parts of the liquid silicone rubber A, 180 # diamond sand 10 parts, 180 # green carbonation, 4 parts of chromium oxide poured into the stirring cylinder, at 1000 The rotation / minute is stirred for 10 minutes, then add 25 parts of the liquid silicone rubber curing agent B, 4.5 parts of liquid paraffin, 1 couparent agent, 0.5 parts of the catalyst, and stir for 1500 rpm for 5 minutes to form uniform. After the slurry, poured into a die length 13 cm, deep 1.5cm, width of 5.5 cm, scraping the flat, standing for 1 hour, then placed in a 100 degree oven to curing for 5 hours, and then demolded after cooling to obtain the abrasive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com