Winding machine of three-freedom-degree linkage winding spindle shaft

A degree of freedom, winding machine technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve problems such as affecting fiber quality, edge rubbing, etc., to ensure quality, avoid rubbing and damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

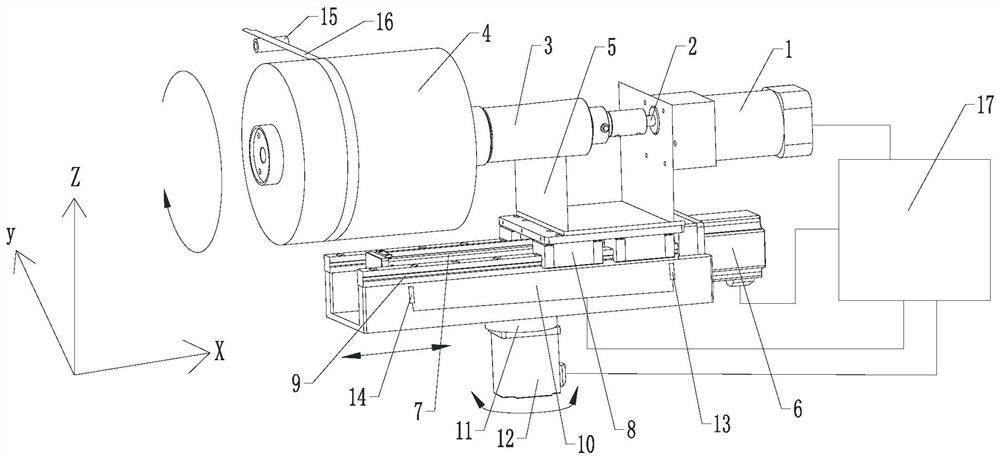

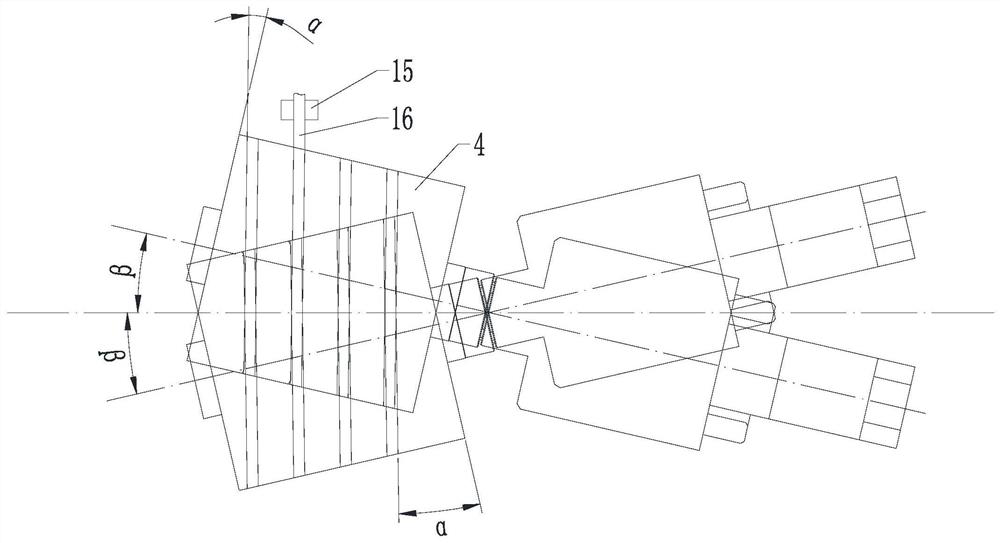

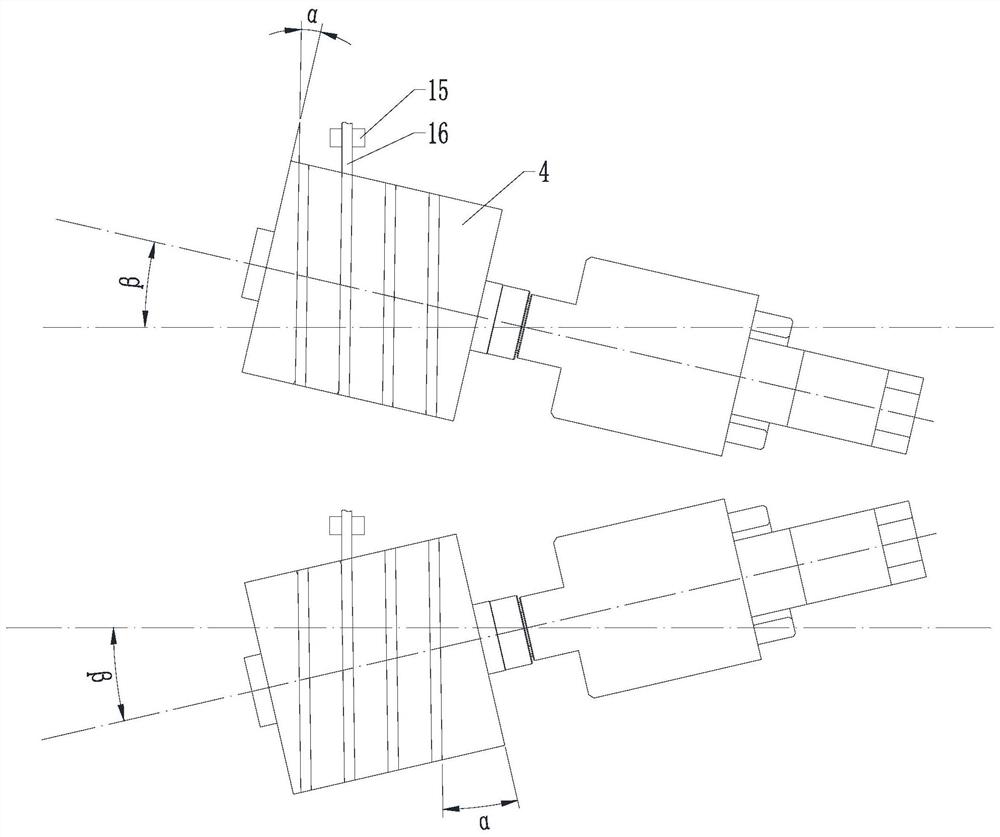

[0023] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0024] For the convenience of understanding, the length direction of the slide rail is defined as the X-axis direction, the width direction of the slide rail is defined as the Y-axis direction, and the direction perpendicular to the slide rail is defined as the Z-axis direction. For the movement of the X-axis, the rotation of the X-axis and the rotation of the Z-axis, the direction where the spindle is located is the left side, the direction where the asynchronous motor is located is the right side, and the direction shown by the arrow in the accompanying drawings is the direction of motion.

[0025] Such as figure 1 As shown, a winding machine with a three-degree-of-freedom linkage winding spindle shaft includes a winding device for winding fibers, a reciprocating yarn guide device for driving the reciprocating motion of the winding devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com