Ca-Ti-Y-Al-Si-O microcrystalline glass brazing filler metal and glass packaging method for nuclear cladding tube port

A technology of glass-ceramics and cladding tubes, which is applied in nuclear engineering, nuclear power generation, measuring devices, etc., to achieve excellent sealing effects, no side effects, radiation resistance, and low viscosity at high temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

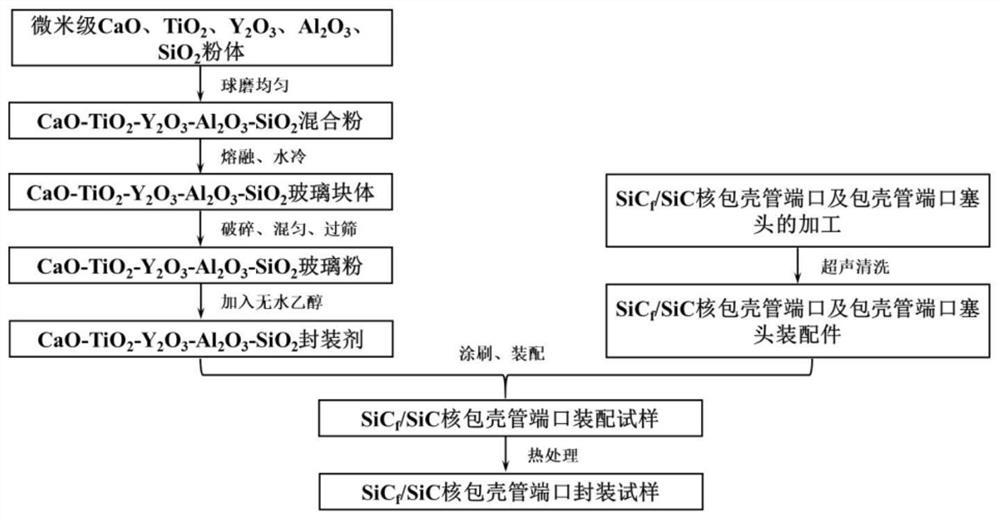

Method used

Image

Examples

Embodiment 1

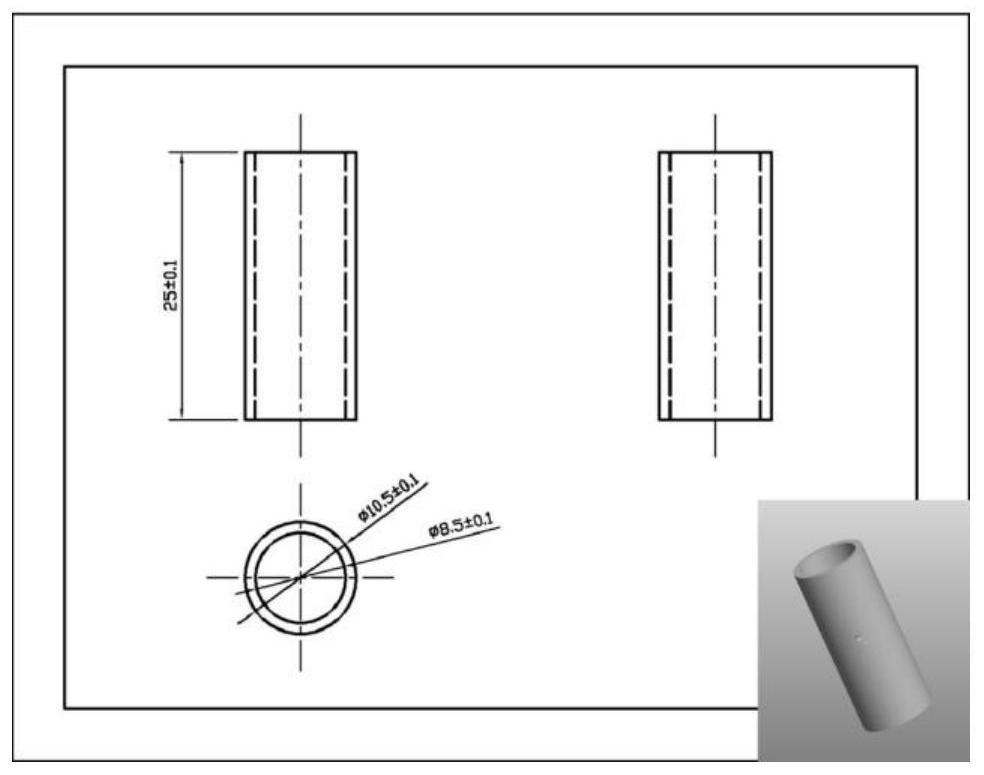

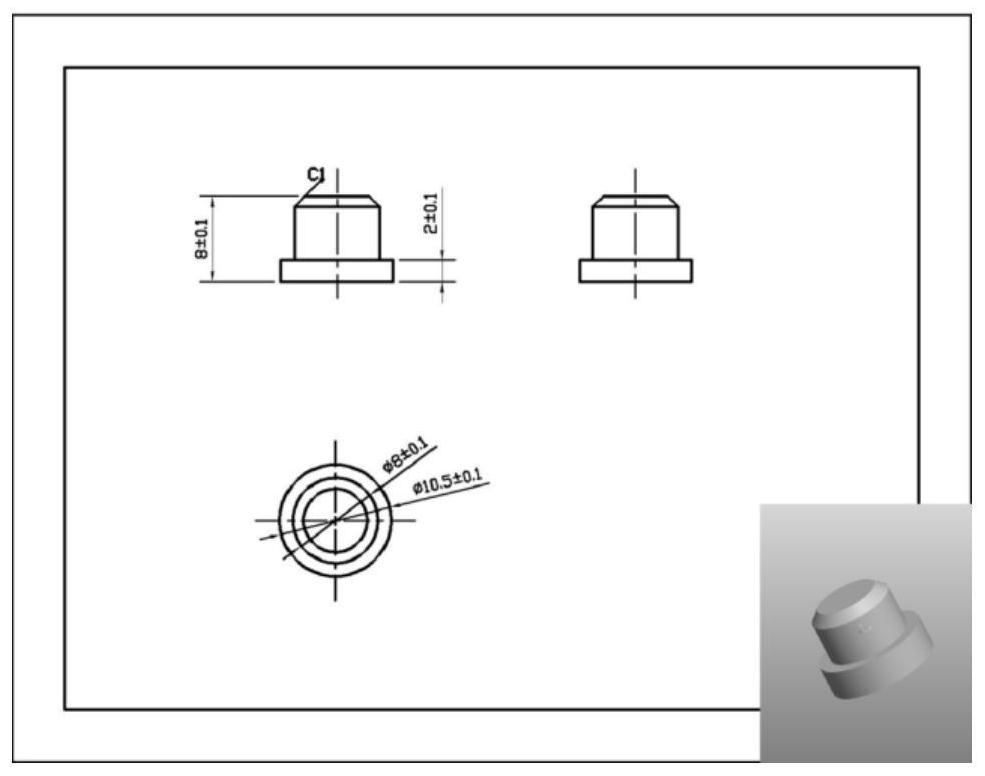

[0033] Use CaO and TiO with a particle size of ~1μm 2 , Y 2 o 3 、Al 2 o 3 , SiO 2 Powder, its mass ratio is: 5% CaO, 5% TiO 2 , 20% of Y 2 o 3 , 30% Al 2 o 3 , 40% SiO 2 , put the four kinds of powders into a ball mill jar and mill them at a speed of 300r / min for 12 hours, put the mixed powders after ball milling in an alumina crucible, and perform heat treatment in an air atmosphere. The heat treatment temperature is 1650°C, and the holding time is 2 Hours, after heat treatment, it is directly placed in cold water for rapid cooling to form a Ca-Ti-Y-Al-Si-O glass block. The glass blocks were crushed and ball-milled, and sieved through a 150-mesh sieve to obtain Ca-Ti-Y-Al-Si-O glass powder. Alcohol is added to the glass powder to form an encapsulating agent, and the mass fraction of the added alcohol is 90%. Coat the encapsulant on the inner wall of the cladding tube and the surface of the cladding tube plug to be encapsulated, place a glass sheet with a thickness...

Embodiment 2

[0035] Use CaO and TiO with a particle size of ~1μm 2 , Y 2 o 3 、Al 2 o 3 , SiO 2 Powder, its mass ratio is: 3% CaO, 2% TiO 2 , 30% of Y 2 o 3 , 25% Al 2 o 3 , 40% SiO 2 , Put the four kinds of powders into the ball milling pot and mill them at a speed of 200r / min for 15 hours, put the mixed powders after ball milling in an alumina crucible, and carry out heat treatment in an air atmosphere. The heat treatment temperature is 1630°C, and the holding time is 2 Hours, after heat treatment, it is directly placed in cold water for rapid cooling to form a Ca-Ti-Y-Al-Si-O glass block. The glass blocks were crushed and ball-milled, and sieved through a 150-mesh sieve to obtain Ca-Ti-Y-Al-Si-O glass powder. Alcohol is added to the glass powder to form an encapsulating agent, and the mass fraction of the added alcohol is 70%. Coat the encapsulant on the inner wall of the cladding tube and the surface of the cladding tube plug to be encapsulated, place a glass sheet with a th...

Embodiment 3

[0037] Use CaO and TiO with a particle size of ~1μm 2 , Y 2 o 3 、Al 2 o 3 , SiO 2 Powder, its mass ratio is: 5% CaO, 3% TiO 2 , 27% of Y 2 o 3 , 20% Al 2 o 3 , 45% SiO 2 , put the four kinds of powders into the ball milling pot and mill them at a speed of 200r / min for 13 hours, put the mixed powders after ball milling in an alumina crucible, and heat-treat them in an air atmosphere. The heat-treatment temperature is 1600°C and the holding time is 4 Hours, after heat treatment, it is directly placed in cold water for rapid cooling to form a Ca-Ti-Y-Al-Si-O glass block. The glass blocks were crushed and ball-milled, and sieved through a 150-mesh sieve to obtain Ca-Ti-Y-Al-Si-O glass powder. Alcohol is added to the glass powder to form an encapsulating agent, and the mass fraction of the added alcohol is 90%. Coat the encapsulant on the inner wall of the cladding tube and the surface of the cladding tube plug to be encapsulated, place a glass sheet with a thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com