Preparation method of mesophase pitch

A technology of mesophase pitch and residence time, which is applied in the field of preparation of mesophase pitch, can solve problems such as poor high temperature thermal stability of mesophase pitch, elevated temperature, and difficulty in asphalt purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

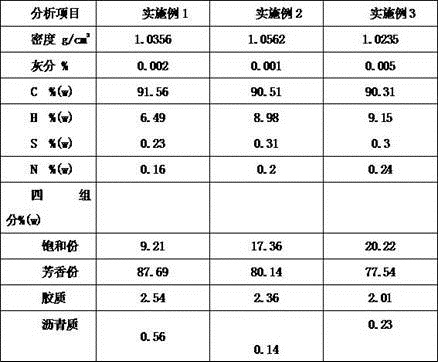

Embodiment 1

[0044] The refined catalytic oil slurry of a refinery is used as the raw material, and its property analysis is shown in Table 1. The raw material enters the preheating device 2 and is heated to 300°C, and then enters the thermal reaction device 4 through the pipeline 3. The reaction temperature of the thermal reaction device 4 is The temperature is 440°C, the reaction pressure is 2.0MPa, and the reaction time is 60min. The reacted material enters the quenching device 6 through the pipeline 5. The temperature of the quenched material is 350°C, and the cooling rate is 30°C / min. Reaction device 9, the reaction temperature of thermal reaction device 9 is 400°C, the reaction pressure is 2.0MPa, the reaction time is 240min, high-temperature water vapor 10 enters from the bottom of thermal reaction device 9, and its volume space velocity is 6h -1 , the produced light distillate components are discharged from the device through the pipeline 8, and the heavy components enter the quench...

Embodiment 2

[0046] The refined catalytic oil slurry in a refinery is used as the raw material, and its property analysis is shown in Table 1. The raw material enters the preheating device 2 and is heated to 420°C, and then enters the thermal reaction device 4 through the pipeline 3. The reaction temperature of the thermal reaction device 4 is is 460°C, the reaction pressure is 1.0MPa, and the reaction time is 10min. The reacted material enters the quenching device 6 through the pipeline 5. The temperature of the quenched material is 380°C, and the cooling rate is 80°C / min. Reaction device 9, the reaction temperature of thermal reaction device 9 is 420°C, the reaction pressure is 1.5MPa, the reaction time is 120min, high-temperature water vapor 10 enters from the bottom of thermal reaction device 9, and its volume space velocity is 15h -1 , the produced light distillate components are discharged from the device through the pipeline 8, and the heavy components enter the quenching device 12 t...

Embodiment 3

[0048] The refined catalytic oil slurry in a refinery is used as the raw material, and its property analysis is shown in Table 1. The raw material enters the preheating device 2 and is heated to 350°C, and then enters the thermal reaction device 4 through the pipeline 3. The reaction temperature of the thermal reaction device 4 is The temperature is 480°C, the reaction pressure is 0.5MPa, and the reaction time is 20min. The reacted material enters the quenching device 6 through the pipeline 5. The temperature of the quenched material is 300°C, and the cooling rate is 45°C / min. Reaction device 9, the reaction temperature of thermal reaction device 9 is 390°C, the reaction pressure is 0.2MPa, the reaction time is 200min, high-temperature water vapor 10 enters from the bottom of thermal reaction device 9, and its volume space velocity is 10h -1 , the produced light distillate components are discharged from the device through the pipeline 8, and the heavy components enter the quenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com