Irregular polypropylene fiber short fiber for high-efficiency filtering, and spinning method thereof

A polypropylene staple fiber and high-efficiency filtration technology, which is applied in the spinning field, can solve the problems of high linear density, small dirt holding capacity, low filtration effect and low filtration accuracy, and achieve improved filtration accuracy and life, material saving, and good shaped holes The effect of machinability

Inactive Publication Date: 2017-04-05

YANGZHOU YONGHUI TEXTILE TECH

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The slubbed filter yarn spun by ordinary polypropylene fiber has low filtering effect and precision, high linear density, and small dirt holding capacity, which can no longer meet the needs of the current domestic and foreign markets. Users have put forward higher requirements for slubbed filter yarn. : The cross-sectional shape of polypropylene fiber is profiled and complicated, forming a larger specific surface area, more voids and microporous structures to accommodate impurities and dirt, to meet the pre-conditions of post-spinning yarns

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

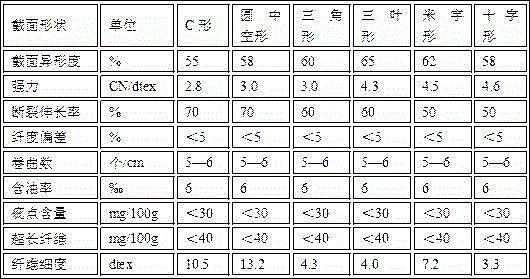

[0016] Taking the spinning fiber specification of 3.3-10.5dtex×64mm as an example, the physical indicators of the fiber are as follows:

[0017]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Powerful | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses an irregular polypropylene fiber short fiber for high-efficiency filtering. The cross section of the polypropylene fiber short fiber is shaped as any form from the following: C-shaped, circular hollow-shaped, trilobal-shaped, cross-shaped, Chinese character mi-shaped and triangular-shaped, the fineness of the polypropylene fiber short fiber is set from 3.3dtex to 13.2 dtex, the length is from 38mm to 102mm, the irregularity is from 50% to 70%, the strength is greater than 3.0CN / dtex, and the polypropylene fiber short fiber comprises an organosilicon activator with a weight percentage content of 0.6+ / -0.02%. The irregular polypropylene fiber short fiber provided by the invention is a filtering material which is suitable for industrial production and satisfies ever increasing requirements and is dedicated to the field of filtering for improving the pollutant holding quantity.

Description

technical field [0001] The invention relates to spinning technology, in particular to a special-shaped polypropylene staple fiber for high-efficiency filtration and a spinning method thereof. Background technique [0002] The slubbed filter yarn spun by ordinary polypropylene fiber has low filtering effect and precision, high linear density, and small dirt holding capacity, which can no longer meet the needs of the current domestic and foreign markets. Users have put forward higher requirements for slubbed filter yarn. : The cross-sectional shape of polypropylene fiber is profiled and complicated, forming a larger specific surface area, more voids and microporous structures to accommodate impurities and dirt, to meet the pre-conditions for post-spinning yarns. Contents of the invention [0003] Purpose of the invention: The purpose of the invention is to solve the deficiencies in the prior art, and provide a special-shaped polypropylene staple fiber for high-efficiency fil...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D01D5/253D01D5/24D01D5/08D01F6/46D01F1/10

Inventor 刘铭时菁菁

Owner YANGZHOU YONGHUI TEXTILE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com