Preparation method of shape memory self-lubricating liner material and antifriction method of inner spherical surface of spherical support fixing shell

A liner material, self-lubricating technology, applied in mechanical equipment, fiber types, pivots, etc., can solve problems such as low bearing capacity, reduced yield and product reliability, and accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a method for preparing a shape-memory self-lubricating liner material, comprising the following steps:

[0038] Mixing the epoxy resin matrix, multifunctional curing agent and tertiary amine accelerator to obtain a shape memory epoxy resin solution;

[0039] mixing the shape memory epoxy resin solution with a solid lubricant to obtain a lubricant dispersion system;

[0040] immersing the fiber fabric in the lubricant dispersion system to obtain a composite fiber fabric;

[0041]The composite fiber fabric is placed in a mold, pressurized and sintered, and a shape-memory self-lubricating gasket material is obtained after demolding.

[0042] In the present invention, if there is no special requirement, the preparation raw materials used are commercially available products well known to those skilled in the art.

[0043] The invention mixes the epoxy resin matrix, the multifunctional curing agent and the tertiary amine accelerator to obtain the shap...

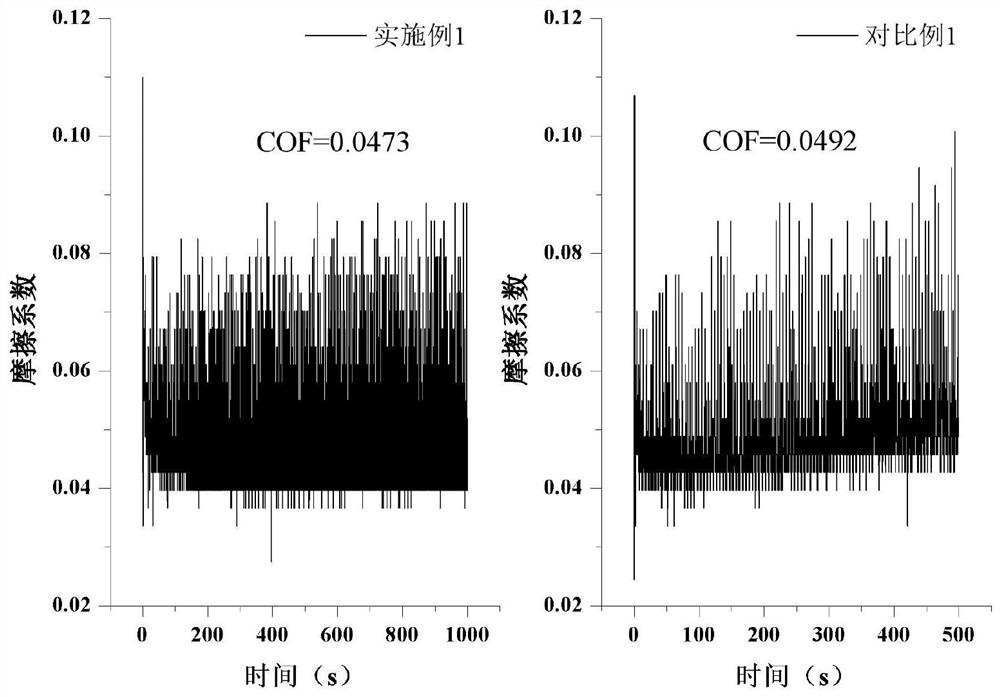

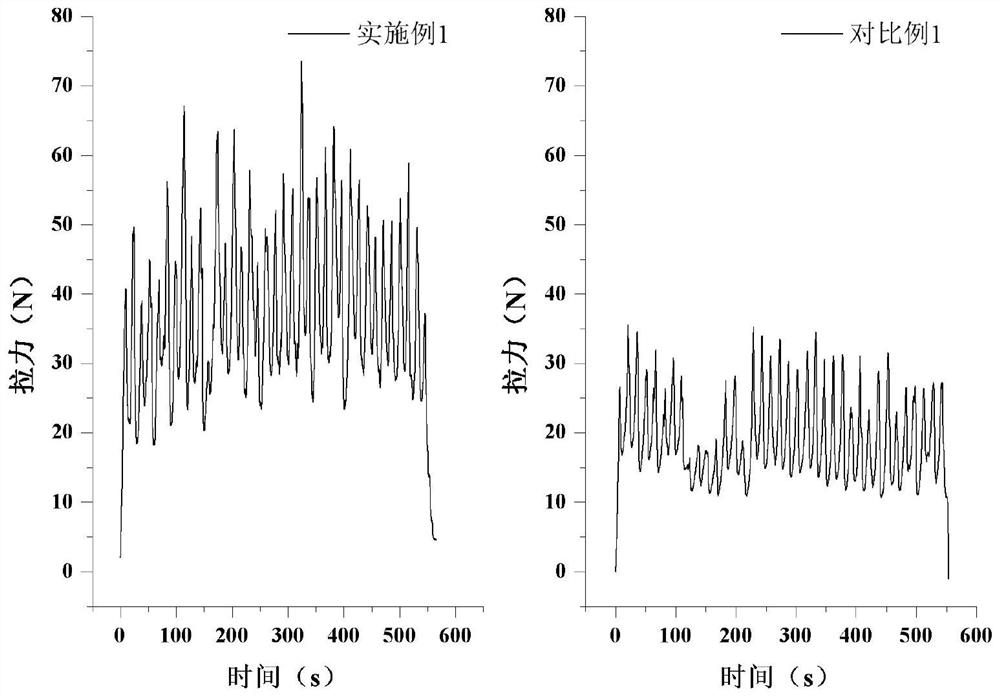

Embodiment 1

[0073] a. Preparation of shape memory epoxy resin solution:

[0074] Mix 0.255 mol of epoxy resin E-51, 0.255 mol of curing agent methyl hexahydrophthalic anhydride, and 1.275 mmol of accelerator triethylamine, and stir evenly to obtain an uncured shape memory epoxy resin solution.

[0075] b. Preparation of lubricant dispersion system:

[0076] 28.60g of graphite with a particle size of 200 mesh and 19.07g of molybdenum disulfide with a particle size of 200 mesh were added as a solid lubricant to the above-mentioned shape memory epoxy resin solution, stirred at a rate of 400rpm for 30min, and ultrasonically treated at an ultrasonic power of 500W for 15min. A uniformly dispersed lubricant dispersion system is obtained.

[0077] c. Dipping:

[0078] The blended fabric of polytetrafluoroethylene fibers and aromatic polyamide fibers is dipped and dried 8 times in the lubricant dispersion system, and soaked for 2 minutes each time to obtain a composite fiber fabric; the polytetr...

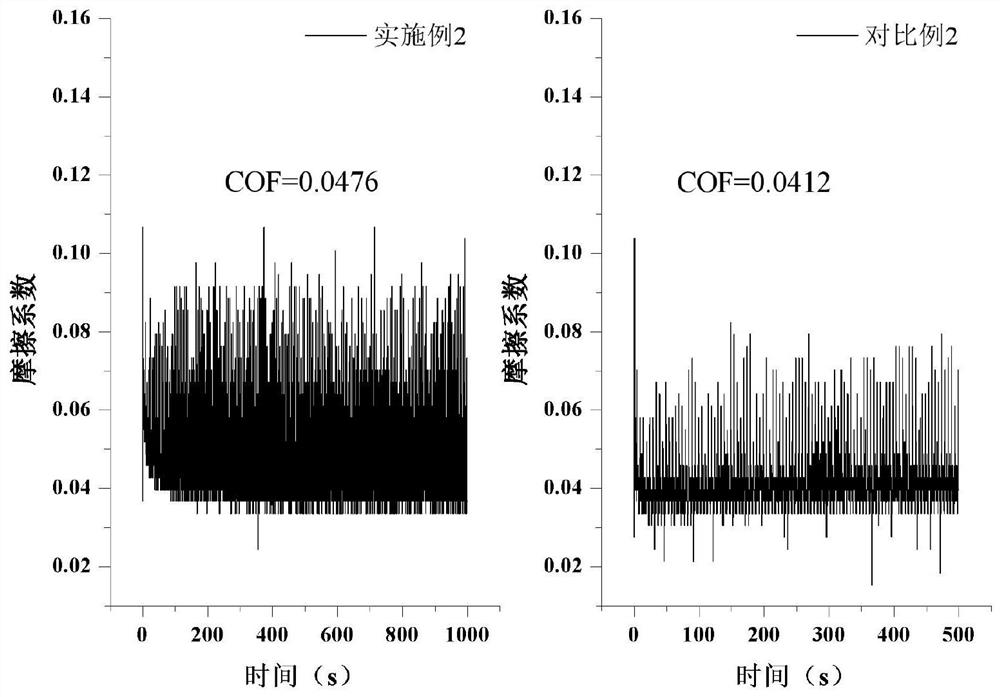

Embodiment 2

[0097] a. Preparation of shape memory epoxy resin solution:

[0098] Mix 0.20mol epoxy resin AG-80, 0.40mol curing agent adipic acid, and 2.0mmol accelerator N,N-dimethylphenethylamine, and stir evenly to obtain an uncured shape memory epoxy resin solution.

[0099] b. Preparation of lubricant dispersion system:

[0100] Add 14.0g of graphite with a particle diameter of 200 mesh and 14.0g of molybdenum disulfide with a particle diameter of 250 mesh as a solid lubricant to the above-mentioned shape memory epoxy resin solution, stir at a rate of 450rpm for 25min, and perform ultrasonic treatment with an ultrasonic power of 400W for 30min. A uniformly dispersed lubricant dispersion system is obtained.

[0101] c. Dipping:

[0102] The blended fabric of polytetrafluoroethylene fiber and aromatic polyamide fiber is impregnated and dried 6 times in the lubricant dispersion system, and soaked for 10 min each time to obtain a composite fiber fabric; the polytetrafluoroethylene fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average peel strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Average peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com